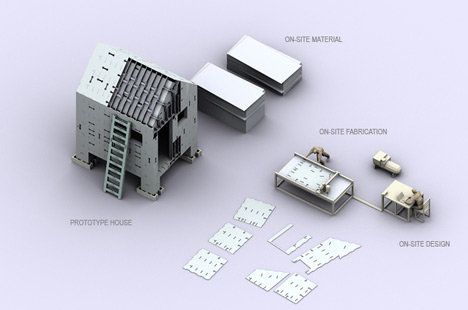

We recently came across an interesting project called The OPEN Prototype Initiative (OPI). It is:

... developing a series of prototypical homes to test a new model for the design, fabrication and assembly of highly responsive places of living.

Founding partners:

More information is available on the OPI website:

We look forward to seeing more from this collaboration.

Taliesin, the Frank Lloyd Wright School of Architecture, posted pictures of their completed Mod.Fab.

[The] prototype residence relies on panelized construction to allow for speed and economy on site or in a factory

PrairieMod tracked their progress from start to finish.

Hat Tip: Jetson Green on February 13, 2009.

The New York Times recently discussed the sustainability of modular housing.

The modular housing industry likes to say that it has always had a few characteristics that today might be considered eco-friendly — from reduced waste to a smaller construction footprint.

But it’s only recently — and increasingly amid the flagging housing market — that manufacturers of factory-built homes have realized that concepts like efficiency and sustainability can make for good business strategy.

Mentioned in the article:

-

Ecohealth Homes Inspired by Caroline McKenna

Ecohealth Homes Inspired by Caroline McKenna

-

LivingHomes

LivingHomes

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

-

New World Home

New World Home

-

Penn Lyon Homes

Penn Lyon Homes

Read the entire article.

(Hat tip: Charles Bevier of Building Systems on February 11, 2009.)

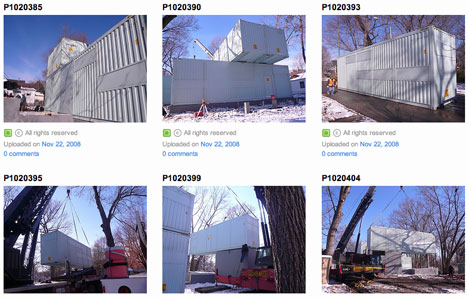

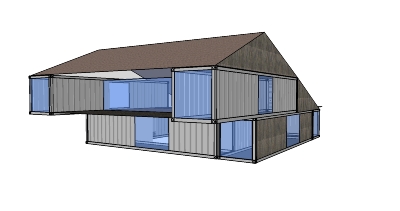

materialicious covered a shipping container house in Kansas City. They found the house via LamiDesign idea log.

The look is very basic. In any case, check out the 53 pictures on Flickr. It's interesting that one section has poured concrete walls.

Back in October, The Guardian provided a gallery of pictures which they consider to be

the best green buildings from the design website Inhabitat

Note: Inhabitat is part of the Guardian Environment Network.

The gallery includes 3 prefab homes:

-

Cellophane House by

Cellophane House by  Kiernan Timberlake Associates

Kiernan Timberlake Associates

-

Redondo Beach house from

DeMaria Design Associates

DeMaria Design Associates

-

a flat pack project by

SYSTEMarchitects and

SYSTEMarchitects and  Gauthier Architects

Gauthier Architects

Hat tip: The Green Blog on October 20, 2008

Jetson Green recently shared pictures of an  Adam Kalkin container house in Maine from 2003:

Adam Kalkin container house in Maine from 2003:

The beautiful home stretches the boundaries of modern design and is truly a work of art. It was created by stacking a dozen orange "reclaimed" shipping containers in a T-shape while replacing some of the steel panels with large windows looking out over the rocky peninsula to Blue Hill Bay.

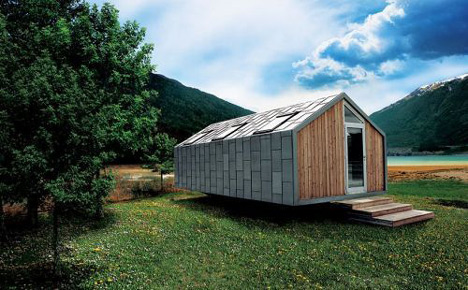

In their February 2009 issue, Dwell Magazine features an article about  American House 08 by architect

American House 08 by architect  William Massie.

William Massie.

For Massie, creating this “transportable” house proved inspirational.

For over a decade, attaching his computer to a laser cutter, he learned how to draw intricate shapes—such as jigsaw patterns for wood paneling—and have the machine cut them out seamlessly. He then bought his own computer numerically controlled (CNC) milling machine, which could drill down into a material to create molds. He was thus able to redefine how standard materials such as concrete, wood, and even rubber were used. They no longer had to be flat or rectangular—they could become sculptural forms.

The prefab part isn't really intended to be practical here:

When the house is moved again, some interior surfaces, such as the plaster ceilings, will, in Massie’s words, “have to be sacrificed.” Redoing them, and reinstalling the floor, will cost about $20,000. The total transport cost, apart from any work to connect the house to the site, will be nearly $45,000. The cost of the house itself? $750,000.

The house is listed on ebay. The starting bid was $480,000 and the current bid is up to $490,100.

Read the Dwell article for more details, then visit Massie's website for numerous pictures and a virtual tour.

(Hat tip: Materialicious on December 22, 2008)

There has been a lot of buzz lately about the  iHouse from

iHouse from  Clayton Homes. They do not offer model information on their main website, though there is a virtual tour of the house.

Clayton Homes. They do not offer model information on their main website, though there is a virtual tour of the house.

The (Maryville, TN) Daily Times interviewed Kevin Clayton, the company's CEO and president, on October 29, 2008.

Metro Pulse had a lengthy article on December 17, 2008:

The core product is a 992-square-foot one-bedroom home featuring a detached “Flex Room” connected by an “Outdoor Living Space” or deck made of recycled materials. If you look at the floor plan ... the main structure looks a little bit like a lower case “i,” with the Flex Room as its dot. Hence the name.

Jetson Green shared some great pictures on January 9, 2009.

TreeHugger had two separate posts on January 10, 2009, one by Lloyd Alter and the other by Brian Merchant.

Last, but not least, a fan created The Clayton iHouse blog. Although not affiliated with Clayton Homes, it is a great source of information.

We're still catching up on old news. In November, Jetson Green covered the  RINCON 5 from

RINCON 5 from  Marmol Radziner Prefab:

Marmol Radziner Prefab:

RINCON is the moniker for their latest modular series, a line of homes that can double as a small prefab dwelling or ancillary living structure, you name it. The name is inspired by the Spanish word for "nook" -- an apt description for this little accessory structure.

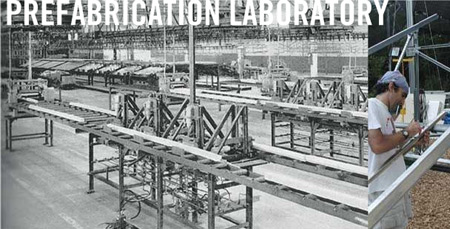

In November, Jetson Green featured a post by one of their sponsors,  Envision Prefab.

Envision Prefab.

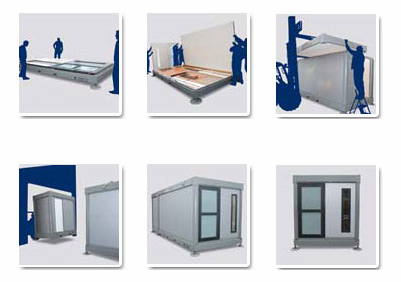

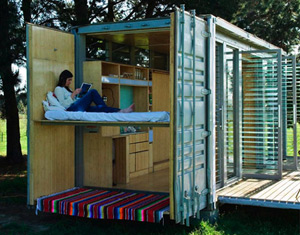

Envision Prefab ... is bringing container architecture to a new level by creating complete modular housing out of these frames.

The home starts with the basic cargo containers. Factory technicians mark out the windows, doors, mechanical, and plumbing vents and cut through the corrugated metal walls. The interior wall is completely removed, and the containers are braced to prevent any deflections.

See the post for photographs of the construction sequence.

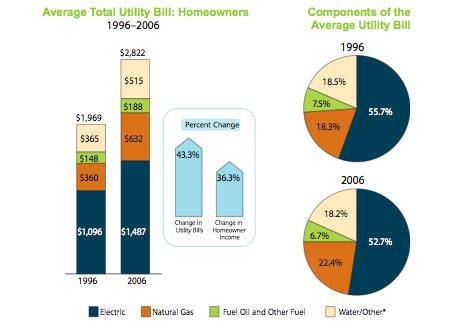

Back in November,  Michelle Kaufmann released a new white paper (pdf) titled "Redefining Cost: A Beacon of Hope Shines through Housing Market Gloom".

Michelle Kaufmann released a new white paper (pdf) titled "Redefining Cost: A Beacon of Hope Shines through Housing Market Gloom".

In it, she says:

The convergence of the financial, energy, and housing crises has essentially become a perfect storm with the power not only to weed out the risky and damaging housing industry practices of old but also to encourage the promulgation of more economically and environmentally sustainable practices going forward.

While the paper doesn't address prefab specifically, it covers issues that could affect the industry. It's definitely worth a look.

Hat tip: Building Systems on November, 27, 2008.

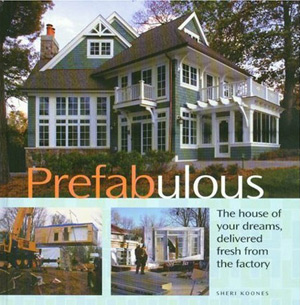

In 2005, Dwell magazine launched a line of co-branded prefab homes with several companies. In October, Time Inc's This Old House (TOH) announced they were following suit (paid subscription required):

... to create the This Old House Home Collection by Bensonwood

Publisher Matt Turck said TOH will get an undisclosed share of revenue. The homes will be priced from $300,000 to $600,000.

Turck added that the pact extends his brand's reputation beyond home improvement.

"Factory-built homes are the future of home building," the publisher said. "We want to connect our brand with the future of home building."

This news comes as the This Old House TV series wraps up construction on a  Bensonwood home that has served as the subject of the show's latest season. Further information on that project is available on the This Old House blog.

Bensonwood home that has served as the subject of the show's latest season. Further information on that project is available on the This Old House blog.

Yesterday's post included a link to a Building Systems blog podcast. Here are a few more prefab-related interviews from their podcast page.

| Person | Company | Minutes |

|---|---|---|

| Tedd Benson |  Bensonwood Homes Bensonwood Homes |

40 |

| Blaine Zulkoski |  North American Log Homes North American Log Homes |

? |

| Michelle Kaufmann |  Michelle Kaufmann Designs Michelle Kaufmann Designs |

30 |

|

Just to keep them all in one post: |

||

| Carl Krave | Pocket Neighborhoods | ? |

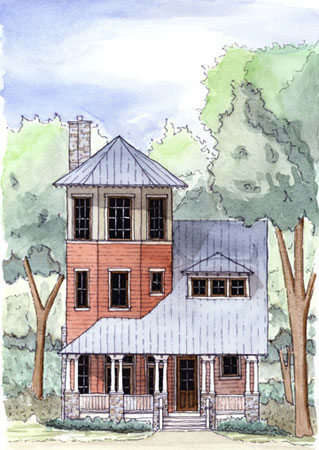

Building Systems blog reported back in November:

Carl Krave, president of Pocket Neighborhoods, a builder and developer in the Tampa Bay, FL ... recently won the coveted Aurora Award for his Glencairn Cottages project.

These green and energy-efficient model homes, which are built off site by Nationwide Custom Homes (Martinsville, VA), replicate the old, historic homes seen in Key West, FL, and Charleston, SC. The project won the award for the best development on less than 100 acres

Worth a listen: their podcast about Krave's strategy.

Worth browsing: Glencairn Cottages

Builder:  Nationwide Custom Homes

Nationwide Custom Homes

Catching up on a backlog of old news. Here's a story out of Austin, Texas:

In about seven hours, Austin builder Gary Bellomy used a 100-foot-tall, 100-ton crane to erect a pair of townhomes that are expected to earn the top rating from Austin Energy's Green Building Program.

Not bad, considering a project this size would typically take months to build. The secret: modular construction.

Companies mentioned:

- Palm Harbor Homes

- Discovery Custom Homes

- Town Builders

- KRDB

Read the full article for details.

Earlier this month, Contemporist shared pictures of the newly finished Johnson Creek  weeHouse in PA.

weeHouse in PA.

Original source: Alchemy blog

Designer:  Alchemy Architects.

Alchemy Architects.

Mocoloco covered the 2+ Weekend House, designed by  Jure Kotnik Arhitekt:

Jure Kotnik Arhitekt:

... the 2+ Weekend House is a container house with a difference - it's made with containers manufactured expressly for housing (vs. cargo containers). "As opposed to the other container projects, which mostly feed on the excess of available cargo containers, ConHouse pushes the development of containers manufactured especially for housing and office purposes."

The company's Conhouse (container house) Web site has lots of details:

See also: more pictures of the 2+ Weekend House.

(Hat tip: materialicious on December 10, 2008; also covered by Treehugger on the same day)

Michelle Kaufmann Designs is receiving the 2008 TOP FIRM Award from residential architect magazine, so I am here to accept the award on the company’s behalf. It is quite an honor...

More from residential architect:

In the five years since she started her firm ... Kaufmann has made remarkable progress in achieving this mission. Michelle Kaufmann Designs (MKD) has built 33 green, modular homes to date, mostly on the West Coast.... Thirty employees buzz busily around the firm's Oakland, Calif., headquarters, which possesses the same design sensibilities as its houses: clean lines; simple, yet high-quality materials; and an overall sense of calm and order.

Since 2006, the firm has built many projects in its own factory, mkConstructs, in Lakewood, Wash.... "Now we're taking what we've learned in all the construction phases and applying that to our designs," says Paul Warner, AIA, a principal at MKD.

Read the full article for details.

Turkish newspaper Hürriyet reports on Turkey's first eco-friendly prefab homes by Orca Yapı Sistemleri:

Orca Yapı began work on the design in 2006. A project request from Sudan required the company to design a steel-structured prefabricated home unit, with a two-year guarantee, that could endure temperatures ranging from plus 50 degrees to minus 50 degrees Celsius. The company added their own requirement of earthquake durability, making it more attractive in the domestic market. The design's first thumbs-up came from the Ministry of Public Works whose tests revealed the house to be durable in earthquakes reaching 7.5 on the Richter scale.

Sustainability and earthquake durability aside, the real draw for the unit is the cost.... The baseline cost for a unit, which does not include any alternative energy production methods like the active solar power water heating system that is installed on the show model in Kocaeli, is $295 per square meter.

That comes out to about $27.50 a square foot. That's in Turkey; I wonder how much it would cost to build the same home here.

The company website is in Turkish, but they do have a video page that's worth a look.

(Hat tip: Treehugger)

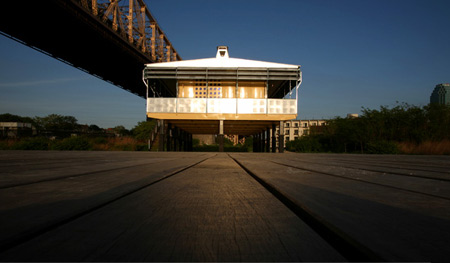

Not a residence, but pretty impressive. Architecture blog Y08 took notice of  LOT-EK's new Puma City:

LOT-EK's new Puma City:

24 shipping containers are retrofitted and transformed into PUMA CITY, a transportable retail and event building that is traveling around the world...

The building is fully dismountable and travels on a cargo ship ... it will be assembled and disassembled a number of times...

(Hat tips: Treehugger, Jetson Green, ecosistema urbano)

We just received an email from Ann Raab at  GreenPod Development:

GreenPod Development:

Our first GreenPod home, Franny’s Pod, named after its owner ... will be complete in a few days!

Members of the press, government officials, and the public are invited to tour Franny's new home, talk with GreenPod designers and staff, and learn more about sustainable living.

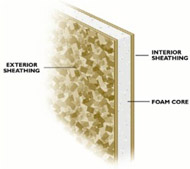

Treehugger's Lloyd Alter recently attended the Greenbuild International Conference and Expo in Boston. He describes Agriboard Structural Insulated Panels (SIPs) made by Agriboard Industries as

perhaps the best thing I saw

We previously covered SIPs and how they are made.

In constrast, an Agriboard SIP:

... uses wheat and rice straw that is normally burned or ploughed under, and builds it into a panel that delivers R-25, not as good as a styrofoam SIP but pretty good and in a form that gives you a tight envelope.

We're still catching up on news from last month. Here's a story worth covering:

Homes for Our Troops is a non-profit organization that provides homes to military personnel with severe injuries or disabilities sustained in active-duty wartime. Tidewater Modular Homes of Virginia Beach teamed up with Nationwide to provide the house for Bartlett, which will be set on its foundation in Chesapeake on Veteran’s Day Nov. 11.

Bartlett, who lives in Norfolk, came to Martinsville on Wednesday for a reception at Nationwide. He toured his future home in progress, stepping through the rooms on a $110,000 pair of prosthetic legs.

His new modular home is 1,475 sf and handicapped-accessible.

Some links:

- more details

-

Tidewater Custom Modular Homes is the local builder

Tidewater Custom Modular Homes is the local builder

-

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

- Homes For Our Troops accepts donations

(Hat tip: Charles Bevier of Building Systems on October 24, 2008)

A couple of weeks ago, materialicious covered Kathy Tafel's KTainer project:

With partners, I own land in a remote part of California. It has wild beauty, and some need of environmental restoration. Our first years there were spent in basic infrastructure such as water and road. To be there on a more regular basis, though, we needed to not spend hours setting up and tearing down a tent each time we visited. My partners built a yurt. I am building a house framed by shipping containers.

According to her website, the KTainer house was made from 4 24' containers which she purchased on Craigslist.

Also on the site, she details the process throughout various stages of construction and shares pictures:

- Overview, including a list of "not its", ie. containers that she did not choose

- Layout

- Site

- Foundation

- Openings

- Deck

- Kitchen

- Roof

- Ladder

Her conclusion:

there is far more romance in the idea of a shipping container home than the actuality of building one. Working with metal is a pain. You need to know metal-working skills or someone who has them. It is dangerous to work with power tools of course, but angle grinders and welders are especially not for the faint of heart. I am of course happy with the result, but this has been harder work than I imagined, and I didn't do the hardest labor.

If you are interested in shipping container homes, or considering building one yourself, Kathy's site is a must-visit.

The winners of the second annual Lifecycle Building Challenge (LBC2 or LBC 2008) were announced recently. About the challenge:

Lifecycle building is designing buildings to facilitate disassembly and material reuse to minimize waste, energy consumption, and associated greenhouse gas emissions. Also known as design for disassembly and design for deconstruction, lifecycle building describes the idea of creating buildings that are stocks of resources for future buildings.

Given those goals, it's no surprise that the three winners in the Building category are prefab:

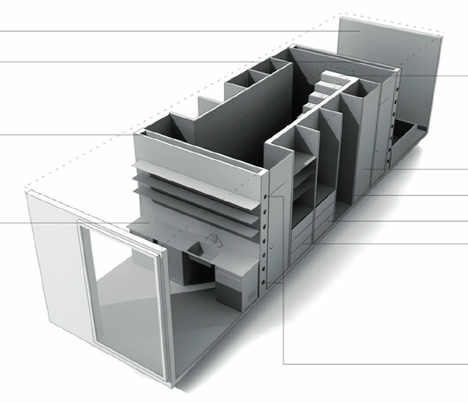

TriPod by Carnegie Mellon University

TriPod is a prototype house demonstrating the "Plug and Play" concept and is designed to provide an innovative alternative to the currently unimaginative housing industry. ... [A] mechanical "core" ... acts as a motherboard that is able [to] accept multiple "pods" that are living, cooking, and sleeping spaces. This modular design allows homeowners to change their homes by adding or subtracting pods to suit their needs over time.

The Workshop by Schemata Workshop

There are two units in the building — in the first iteration the first story is an office; the second is an apartment. The building is elevated on concrete piers and cantilevers over an existing structure on-site

Loblolly House by

Loblolly House by  KieranTimberlake Associates.

KieranTimberlake Associates.

(See our previous coverage of Loblolly House.)

The challenge is sponsored by West Coast Green, U.S. Environmental Protection Agency, Building Materials Reuse Association, American Institute of Architects and Southface.

(Hat Tip: Jetson Green on October 29, 2008)

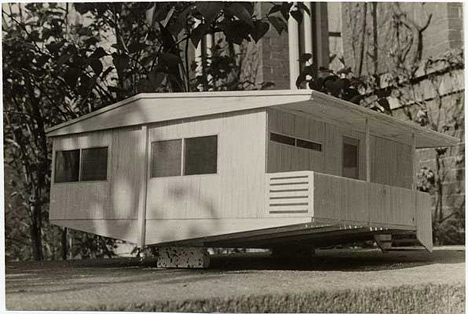

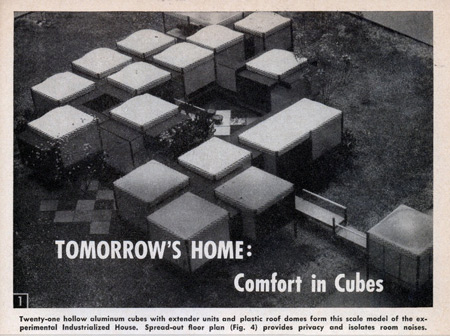

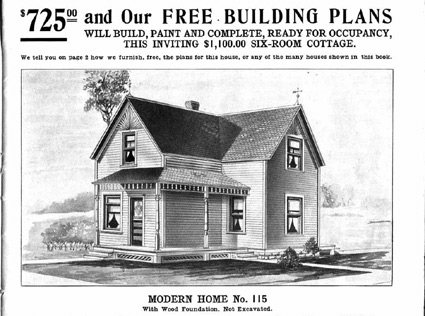

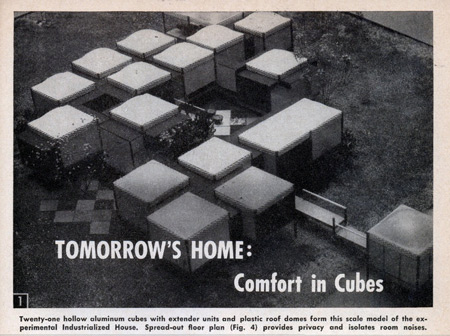

The goal of prefab is clear:

For more than a century, architects and builders have strived toward a prefabricated, industrialized house, one made in a factory so that economies of scale would be realized and the product would be affordable to all home buyers.

It's worth remembering that the current "stick built" process was itself an important innovation, "prefabricating" the basic components:

Until the 1830s, most houses in America were built with post and beam framing. All the pieces were hand-hewn and held in place with complex joinery, and home building was a time-consuming, costly process. Around then, however, steam-driven saws that could produce large quantities of accurately sized building lumber and machines that made huge quantities of iron nails began to appear in the larger cities.

An enterprising Chicago building contractor, George Washington Snow, saw the potential for these new products to revolutionize the building industry. He devised a method of framing that was much faster and far less costly.

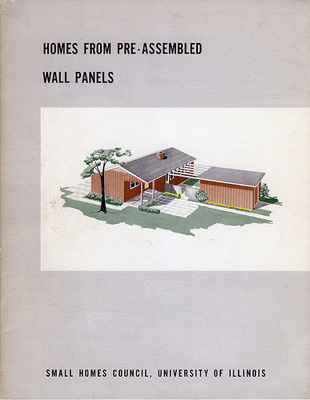

One step forward in the meantime: panels (6% of homes built in the US in 2007).

the 2-by-4 stud walls sometimes are assembled in factories and hauled to a job site, an approach called panelizing.

A bigger step: modular (3% of homes built in the US in 2007).

a method of building in a factory an entire conventional wood-framed house in sections, loading each one onto a flatbed trailer, trucking it to a job site and then setting it in place with a crane.

Read the whole article for a few details on pros, cons, and possible futures.

Last month, The Daily Telegraph in the UK compiled a list of prefab products, describing them as

a burgeoning crop of 'instant' homes that take the prefab to a whole new level.

Included on the list:

| model | designer | ||

|---|---|---|---|

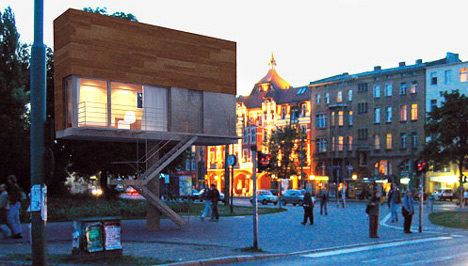

| The Loft Cube | Werner Aisslinger | ||

| 39-55 sq m (420-592 sf) |

£63,500 - £88,500 ($95,496 - $133,042) |

||

Micro Compact Home Micro Compact Home |

Richard Horden of  Horden Cherry Lee Horden Cherry Lee |

||

| 2.6 m cubic units (8.53 ft) |

about £26,000 ($39,086) excluding installation |

||

| Homes 2 Go | Dutch company Spacebox, brought to Britain by Benfield ATT Homes | ||

| 18 sq m (194 sf) |

£22,950 ($34,500) excluding delivery |

||

| Weberhaus | |||

| 200 sq m (2,153 sf) |

from £300,000 ($450,990) | ||

M-house M-house |

Tim Pyne | ||

| 100 sq m (1,076 sf) |

£147,500 ($221,736) | ||

| Eco Pod | Aidan Quinn of Eco Hab | ||

| 28 sq m (301 sf) |

£30,000 ($45,099) | ||

Read the full article for pictures and further details.

Here's an interesting modular development that was announced last month:

Haven Custom Homes ... and Sanctuary Communities have begun construction on the first home in Sanctuary Village, a Traditional Neighborhood Development (TND) located in the western mountains of North Carolina ...

Sanctuary Village will be a walkable, mixed-use village that will encompass 24 acres of multi-generational living with mansion flats, village houses, tree houses, mountain cottages and a civic/commercial component that will include shops, cafes, book stores, cultural events and community gathering spots a short stroll from homes.

We found this explanation of a Traditional Neighborhood Development:

a comprehensive planning system that includes a variety of housing types and land uses in a defined area. The variety of uses permits educational facilities, civic buildings and commercial establishments to be located within walking distance of private homes...

Haven Custom Homes emphasizes the advantages of building "in an off-site, climate controlled environment where the materials used in your home are protected from the weather."

- Precision construction resulting in straight walls, square corners, fitted windows and flat ceilings.

- Extra reinforcements in bearing walls.

- Move in 16-23 weeks after execution of a contract and your approval of final drawings and finish schedules.

Facts:

-

developers: Tim and Iva Ryan of

Sanctuary Communities

Sanctuary Communities

-

builder:

Haven Custom Homes

Haven Custom Homes

-

designer:

Allison Ramsey Architects (strategic partner)

Allison Ramsey Architects (strategic partner)

- location: "five blocks from Franklin's historic Main Street"

Links:

(Hat tip: Building Systems on October 29, 2008)

In September, Charles Bevier of Building Systems blog mentioned a 2-page spread in the Fall/Winter 2008 issue of Better Homes & Gardens' New Home Magazine (BH&G).

BH&G shines the spotlight on the Gull Island.... The design is one of many Poole has created for ... the Southeast market, homes that are turnkeyed by a network of authorized builders.

The blog post summarizes comments by Bill Murray, general manager of HandCrafted, on the advantages of modular construction:

- less time (120 days full turnkey versus 12 to 18 months for site building the old fashioned way)

- meticulous inspection

- modular units are constructed in the controlled environment and sealed from weather before shipping to the jobsite

The issue will be in newsstands through November.

Two weeks ago, the Christian Science Monitor featured Everhouse, a simple design meant to address the post-hurricane housing shortage near the Gulf Coast:

700,000 homes damaged ... and 250,000 homes destroyed

The designer of Everhouse looked to the advantages of prefabrication to help.

To keep costs down, the components of an Everhouse are made by a factory in Palatka, Fla., and then delivered to the land where each unit will be built. And like a desk from Ikea, the pieces arrive with all the necessary materials included...

They opted for a “panelized” design, because the concrete panels are easy to transport and give both the designer and homeowner a good amount of flexibility in house plans.

Key benefit: the shell can be assembled in one day.

The company hopes to produce 1,500 homes per year.

Sawyer also sees a shortage of skilled construction labor in the region. Read the article for his proposed solution.

From the husband and wife team at  Taalman Koch Architecture comes news of a small development of 3 iT houses: Three Junipers.

Taalman Koch Architecture comes news of a small development of 3 iT houses: Three Junipers.

Situated on 5 acres of pristine high desert landscape, each house offers an uninterrupted view of Pipes Canyon and the Pioneertown sawtooth peaks...

The iT house utilizes a "light touch" installation approach, minimizing the construction footprint through use of smaller scale, modular elements and minimal packaging material.

In tandem with that announcement, a new itHouse website has been launched with:

- iT house configuration options

- details on the framing system

- explanation of the on-site assembly

Also worth a look: an informative blog following the construction of the first iT house.

(Hat tip: Jetson Green)

Last month, the New York Times covered a new prefab home in Culver City, CA designed by  Sander Architects:

Sander Architects:

Inspired by the house that Charles and Ray Eames created in 1949 from a prefabricated steel frame and doors, windows and the like ordered from a catalog, the architects took the project on the condition that they could pursue a novel strategy. Besides using acrylic, Panelite, recycled steel and Styrofoam, they would try unusual ingredients like sunflower husks for wall panels and bookshelves, and blue jeans (for insulation).

Some facts about the house:

- 4,200 square feet

- 30 feet high (due to zoning)

- took 3 years to plan and construct the entire project

Final construction cost:

$528,000, only about a third of the going rate for architect-designed houses of this size in the Los Angeles area.

That comes out to about $125/sf. Not bad.

Check out a slideshow of the house (13 pictures). Read the entire article for more details.

Good Morning America's weather anchor, Sam Champion, recently reported from the Smart Home: Green and Wired exhibit at Chicago's Museum of Science and Industry. Check out their video and pictures. Though not mentioned there, the Smart Home is the  mkSolaire by

mkSolaire by  Michelle Kaufmann Designs.

Michelle Kaufmann Designs.

The exhibit runs through January 4, 2009. (See our earlier post for more info.)

Back in March, Swedish designer  Kjellgren Kaminsky Architecture and developer

Kjellgren Kaminsky Architecture and developer  Emrahus presented six prefabricated "passive" homes at the Hem & Villa housing fair in Malmö, Sweden, with a second presentation last month.

Emrahus presented six prefabricated "passive" homes at the Hem & Villa housing fair in Malmö, Sweden, with a second presentation last month.

Here's a paraphrase from Google's translation of the Emrahus home page:

The reason that we no longer need a heat source is that the house has well insulated walls and ceiling ... which retains the heat generated by household appliances, lights, TV set, and people who live in the house.

The houses:

| model | br | size |

|---|---|---|

| Villa VÄRDE | 3 | 1,292 sf |

| Villa Mittskepp | 2 | 1,722 sf |

| Villa Sida Vid Sida | 2 | 1,722 sf |

| Villa TÅRTAN | 4 | 1,862 sf |

| Villa Fixa | 4 | 2,045 sf |

| Villa Dragspel | 2 - 4 | 1,076 - 2,153 sf |

Blog coverage:

Dezeen on March 19th, 2008.

CubeMe on March 26, 2008

Best Houses and Home Design on March 30, 2008

Jetson Green on October 7, 2008

Inhabitat's Prefab Friday on October 17, 2008

In Italy,  Giacomo Guidotti e Riccarda Guidotti Studio di Architettura designed a home that uses prefabricated concrete wall panels as the exterior cladding. That's common in commercial and industrial buildings but rarely seen in residential construction.

Giacomo Guidotti e Riccarda Guidotti Studio di Architettura designed a home that uses prefabricated concrete wall panels as the exterior cladding. That's common in commercial and industrial buildings but rarely seen in residential construction.

One advantage of this method: the concrete forms both the exterior and interior wall surfaces, reducing time spent on finishes.

(Hat tip: materialicious)

The Swiss Architecture Museum included the home in an exhibition last year:

The Casa Grossi in Monte Carasso (2000-04) is particularly interesting. It is a narrow, rectangular building, a dwelling on the fringe of the building zone. This minimalist structure, clad with prefabricated concrete elements, conveys an impression of being hermetically sealed to the outside world, but surprises us with an atrium inside - serving as both a stairwell and an access core - lit from a roof light on the 2nd floor.

Here's some background information on prefabricated concrete wall panels from an excellent reference site called the Whole Building Design Guide.

Paul E. Gaudette explains:

Architectural precast concrete has been used since the early twentieth century and came into wide use in the 1960s. The exterior surface of precast concrete can vary from an exposed aggregate finish that is highly ornamental to a form face finish.... Some precast panels act as column covers while others extend over several floors in height and incorporate window openings...

In general, prefabricated concrete wall panels can serve one of two purposes:

Precast cladding or curtain walls are the most common use of precast concrete for building envelopes. These types of precast concrete panels do not transfer vertical loads but simply enclose the space. They are only designed to resist wind, seismic forces generated by their own weight, and forces required to transfer the weight of the panel to the support....

Load-bearing wall units resist and transfer loads from other elements and cannot be removed without affecting the strength or stability of the building.

It's not clear whether the Casa Grossi wall panels are load bearing.

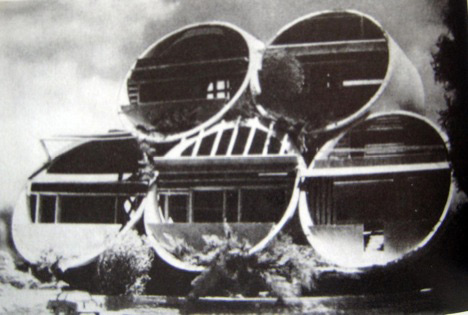

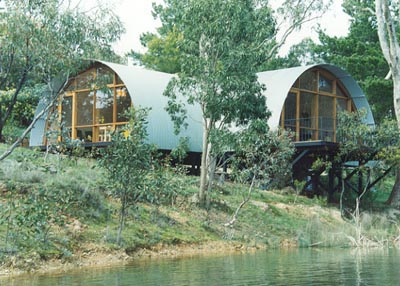

materialicious covers a different sort of prefab product that's been around for a while. From the company site:

The Igloo Satellite Cabin is designed to provide safe, reliable accommodation in remote areas. It has been used for over 25 years in conditions ranging from the tropics to polar icecaps. Units can be flown by helicopter fully assembled, and often fully equipped, to locations inaccessible by road transport. Igloos are ideal short-term accommodation for exploration and research, as well as an attractive alternative for eco-tourism.

Igloos can be lengthened to six or more metres by adding sets of extension panels, or interlinked by tunnels to provide a complete weatherproof base.

The Australian Antarctic Division has a bit more info on the history of the cabins:

2007 marked the 25th year since the first fibreglass Igloo Satellite Cabin was designed and manufactured in Tasmania. As at January 2008, 159 Igloos had been purchased by 45 institutes and individuals in 18 countries, with the majority for use in Antarctica.

More details:

- designed by the late Malcolm Wallhead

-

now manufactured under license by

Penguin Composites

Penguin Composites

- nicknamed “apples”

Clayton homes is holding a showcase of homes this Friday, Saturday & Sunday in Knoxville:

Clayton homes is holding a showcase of homes this Friday, Saturday & Sunday in Knoxville:

This is your opportunity ... to tour dozens of new homes without wasting gas or walking too much. Examine the amenities and style available in today's housing.

Whether you are looking to buy or just looking, it will be the one time this year to see so many houses in one place.

See our earlier post for more details on the company and their previous showcase.

According to their website, the following homes will be on display in Knoxville:

| 4 BR, 2 Bath | Size | ||

|---|---|---|---|

| Fireside II | 2,048 sf | ||

| 3 BR, 2 Bath | Size | ||

| Avondale Marquis | 1,848 sf | ||

| Avondale | 2,048 sf | ||

| Blazer | 1,088 sf | ||

| Blue Ridge | 1,216 sf | ||

| Century | 2,176 sf | ||

| Cumberland Marquis | 1,680 sf | ||

| 2,112 sf | |||

| Elevation Series | 1,344 sf | ||

| 1,568 sf | |||

| Elkmont | 1,456 sf | ||

| 1,680 sf | |||

| Esprit | 1,064 sf | ||

| Excel | 1,216 sf | ||

| Glencrest | 1,792 sf | ||

| Heartlander | 1,568 sf | ||

| 1,680 sf | |||

| 2,128 sf | |||

| Manchester | 1,216 sf | ||

| Mountaineer | 1,280 sf | ||

| Norris | 2,432 sf | ||

| Pinebrook | 1,568 sf | ||

| Pinecrest | 1,680 sf | ||

| River Run - Original | 1,344 sf | ||

| River Run | 1,664 sf | ||

| Worthington | 1,056 sf | ||

| Worthington - Original | 1,568 sf | ||

| 2 BR, 2 Bath | Size | ||

| Community | 1,056 sf | ||

| I-Home, Green House | 1,280 sf | ||

One thing we couldn't tell from their site: which are "modular" (built to local codes) vs. "manufactured" (HUD code).

We recently received an email from  Blu Homes.

Blu Homes.

According to their website:

Our first homes are under development in Utah and Massachusetts, and are expected to be completed in Winter 2008.

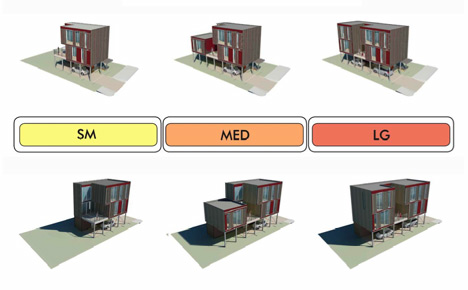

All of their modular homes are fully finished, with a fabrication time of 4-6 weeks and installation time of less than 10 days. They offer several models:

| model | size | baths | price range |

|---|---|---|---|

| Origin | studio - 2 BR | 1 | $50,000 - $115,000 |

| Retreat | 2 BR | 2 | $165,000 - $195,000 |

| 3 BR | 2 | $210,000 - $255,000 | |

| Balance | 2 BR | 1 | $125,000 - $150,000 |

| 2 BR + office | 2 | $165,000 - $195,000 | |

They also offer "Flex" spaces to enlarge an existing home.

From their site:

Preston at Jetson Green has covered the company:

- Blu Homes Launches Convenient, Green, Affordable Abodes

- Blu Homes Moving Forward with Modern, Green, and Affordable Homes

As did Andrew Stone of Active Rain.

Michelle Kaufmann Designs recently sent us an email announcing the launch of their latest home design, the

Michelle Kaufmann Designs recently sent us an email announcing the launch of their latest home design, the  mkHearth.

mkHearth.

Inspired by the natural beauty found in rural structures in the american landscapes, the mkHearth™ home is a sustainable approach to the modern farmhouse. With flowing spaces that organically open to one another, the mkHearth™ home revolves around the center hearth space, a fireplace/cabinetry that circulates up the 3 stories.

Links:

- Images

- Videos

- Floorplans

- “Test drive” it on your property using Google Earth.

Recent coverage:

Preston at Jetson Green loves it.

Stephanie at Apartment Therapy Re-Nest says:

Kaufmann's signature touches are evident in the clean, modern lines, and the way each room seamlessly flows into the next.

The one thing we always love about each of Kaufmann's designs is that they look like the perfect place to throw a party. The kitchen always opens to the dining room, to the living room, to outdoor space. The mkHearth is no exception.

Bridgette Steffen covered the house for Inhabitat's Prefab Friday:

We always love seeing hot designers come out with their next hit– and Michelle Kaufmann’s new mkHearth is likely to be the new hot prefab design.

A real estate agent and a mortgage broker are co-hosting a seminar on modernist prefab next month in the San Francisco Bay Area:

This unique engagement will bring together leading professionals and experts in the field of building, design, real estate, and finance. Anyone who is contemplating the possibility of building a modernist prefab or custom home in Marin County should try to attend this event. Attendance is extremely limited and attendees will be selected on a first registered, first accepted basis.

(Hat tip: Live Modern)

Last month, the San Francisco Chronicle published an article on West Coast Green's showhome, the Harbinger House from  SG Blocks LLC:

SG Blocks LLC:

What makes this year's showcase home different from the prefab modular model seen last year [MKD's

mkLotus] in San Francisco is not all the green bells and whistles ... it's the actual framework of the house that is truly innovative. This year's showstopper is made from five 40-foot-long shipping containers that once roamed the high seas

The article repeated a comment we've seen a few times:

a layman can't tell that, underneath its sleek lines, Harbinger was once a collection of lowly shipping crates

The advantages of shipping containers?

They're made of heavy-gauge steel, which holds up nicely in a hurricane or earthquake, but is usually too expensive to use in construction. [SG Blocks] gets the containers cheap - $500 to $2,000 a pop - because the fuel costs to ship them back empty to China or other places overseas are prohibitive. Because of the United States' huge trade imbalance, there are many empty containers lying around.

Harbinger details:

- made from 5 shipping containers

- 2 stories

- 1,700 square feet

- about 5% less expensive than building in wood or other conventional materials

- can be built 40% faster

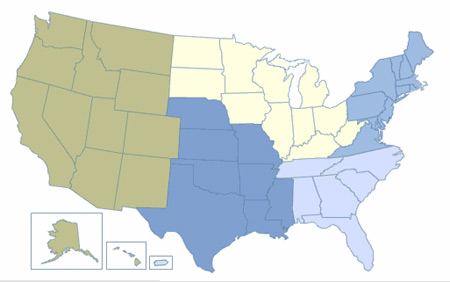

SG Blocks facts:

- founder: David Cross

- location: St. Louis

- has built 6 single-family homes in the US (designed by Lawrence Group)

- 400-unit elder-care facility in Oceanside, CA will be unveiled soon

If you are planning to attend A Clean Break in Philadelphia this weekend, don't miss their presentations being held across the street from the exhibit. Here's one:

Rockhill & Associates

Rockhill & AssociatesEach will discuss their unique modular programs and successes with this chosen method of construction, particularly as an affordable and environmentally-friendly solution to land vacancy and community revitalization.

Design blog Dezeen reports on the Mini House, which takes advantage of new zoning laws in Sweden:

Since January 1st 2008 Swedish property owners are allowed to build a 15 sqm house on their land without a building permit.

The details:

- indoor space: 15 square meters (161.5 sf)

- outdoor space: 15 square meters (161.5 sf)

- 2 people can assemble in 1-2 days

- built with SIPS (panels made of plywood and styrofoam)

- 8 components per house (assembly process shown on the Nordic Marine site)

- requires site preparation of a foundation e.g. concrete slab

- won the Innovation Award 2008 from the Swedish Chamber of Commerce in the UK

More about the concept:

Mini house is a “friggebod” concept which brings some fun and excitement to a dull and conservative market. The concept means prefabrication, flat-pack delivery and weekend-long build-up! Building a house should be fun and easy. Kind of like putting together an Ikea cabinet!

(As best we can tell, friggebod means garden hut or shed.)

See the original post for 11 pictures and more details.

(Hat tip: Treehugger)

Tonight (Oct. 16) from 7:00-10:00 pm is opening night for A Clean Break: "An exhibition of modern prefab architecture and high-design, low-waste innovations for the urban environment."

The full exhibition runs from Oct. 17-30. Their description:

... a pop-up neighborhood of modern and sustainable design with an emphasis on modular and prefabricated homes. The outdoor exhibition offers full-scale homes to tour, installations by architects, urban farming, transportation, environmentally-friendly furniture, public art and other high-design, low-waste products.

See our Oct. 1 post (linked below) for more details.

If you are considering a modular home and live near Boston, MA or Providence, RI:

- Learn What A Full Service Builder Does For You.

- Discover The Benefits Of Modular Construction.

- Understand The True Cost Of "Drop Ship" Homes.

- Permitting Process

- Tear Downs & Rebuilds

- Popularity of in-law-additions

- Free Mortgage & Financial Information.

A little more info on the company:

RDA Inc. offers full real estate, permitting, financing and construction services to handle the new home building process from concept through completion.

Interesting to note, they build only  Westchester Modular Homes.

Westchester Modular Homes.

Their site offers additional information:

- homes offered

- "All In One Day" - photos of installing the modules by crane

- an overview of modular construction

- company background

(Hat tip: Patriot Ledger, Quincy, MA)

Update: fixed the city in the title.

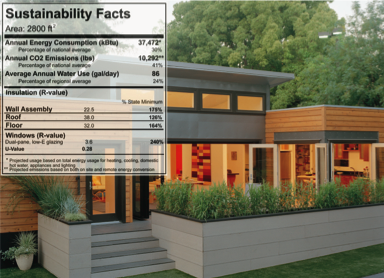

Last week,  Michelle Kaufmann Designs released a white paper on "nutrition labels for homes":

Michelle Kaufmann Designs released a white paper on "nutrition labels for homes":

Green homes are in demand. Buying a green home, however, can be a mystifying, exasperating process. With all the various green home labels and certifications available, buyers want for a way to compare the sustainability of one for-sale home to another. Applying a universal sustainability label to homes, just as we apply nutrition labels to food, would answer this need and further encourage the growth of the green housing market...

By coincidence, we just read an article in Green Building Elements that suggests France already has a good start. The article covers the EvolutiV house by designer  Olgga Architectes:

Olgga Architectes:

The media in France AND the architecture firm who designed the house feel compelled to advertise efficiency in terms of a single number that is easy to understand and can be used to compare this home to others one might choose. I’ve rarely if ever seen that in discussion of US prefab options (or other green homes) - outside of a LEED rating, we’re often left to guess exactly how eco-friendly that home is. We’d love to see this become more widespread in the US - information is power, and simple, objective numbers like this can help us separate the truly eco-friendly from innovative designs that are green in name (or advertising) only.

On the New York Times' Freakonomics blog, Annika Mengisen wonders whether prefab will ever catch on. For answers, she questioned two authors of prefab books, Allison Arieff and James Trulove.

Here are the questions posed; read the full post for their answers.

- Where do prefab houses stand in the U.S. real estate market?

- What, if anything, is the housing crisis doing to prefab?

- What would push prefab beyond a niche market?

- If prefab did catch on, what would the economic implications be?

- What does prefab do for the environment?

- What could prefab do for storm-prone areas?

Just a reminder:

There will be a  Marmol Radziner Open House in Venice, CA this Sunday, October 12, from 2pm - 5pm. Free but reservation required.

Marmol Radziner Open House in Venice, CA this Sunday, October 12, from 2pm - 5pm. Free but reservation required.

Next week you can hear firm principal Leo Marmol, FAIA. Wednesday, October 15, 6pm - 8pm ($22).

Clayton Homes is holding a Showcase of Homes at the Triad Center in Greensboro, NC this weekend, October 10-12. From the press release:

Clayton Homes is holding a Showcase of Homes at the Triad Center in Greensboro, NC this weekend, October 10-12. From the press release:

Literally, Clayton Homes constructs a temporary neighborhood in the parking lot of The Triad Center, fully adorned with sidewalks, landscaping, mailboxes and street signs. The Showcase of Homes provides an opportunity for people to tour a variety of manufactured homes and see how dramatically the homes have changed in recent years.

What to expect:

- 20 new, fully-furnished homes on display

- on-the-spot financing

- hot dogs, drinks and popcorn

- $100 gas card drawings each half hour

Clayton CEO Kevin Clayton explains:

Our unofficial motto is 'Best Home -- Best Price' and we take that very seriously.

It has been his mission since taking over as CEO ten years ago to produce manufactured housing that surpasses site-built homes in look, quality, and value.

Clayton Homes produces both "manufactured" and "modular" housing. These terms have a specific meaning in the industry, part of which is covered on their website:

Manufactured Home: Built entirely in the factory under federal code administered by the Department of Housing and Urban Development (HUD).... Covers single or multi-section homes and includes transport to the site and installation.

The industry stopped using the term "mobile home" (and presumably "trailer home") when the HUD code became effective June 15, 1976. Not mentioned: manufactured homes do NOT qualify for a traditional mortgage, in part because the homes tend to lose value every year.

Modular Home: Built to state, local or regional code where the home will be located. System-built homes are transported to sites and installed.

These homes are built to the same standards as conventional "site-built" homes and qualify for a standard mortgage. (In fact they are often somewhat stronger in order to survive transportation and installation by crane.)

At least one home in the Showcase had 2 stories (see above), so it appears that a mix of both types will be shown.

More about Clayton Homes:

- owned by Warren Buffet's Berkshire Hathaway

- recent news coverage outlines how they've avoided the current sub-prime issues

We didn't make it to this year's West Coast Green, but followed the coverage of those who did. Most interesting: SG Blocks' Harbinger show house.

We previously gave an overview of the house in the run-up to the show. The home was designed by Lawrence Group and built by SG Blocks, SG standing for "sustainable, green."

Inhabitat visited and gave a full review. I found this quote about containers particularly interesting:

The same local skilled workers who repair the containers are hired to repurpose them into house modules, which can then be easily shipped on trains. This process translates into a miniscule transportation footprint and blazingly fast build times: “when you deliver the finished components to site, you can install up to 12 containers using one crane in one day - that’s the equivalent of a 5,000 square foot house that is set in place in one day”.

Preston over at Jetson Green toured the house.

Everyone I talked to loved it. You might think that a shipping container home would feel closed-in and constrictive, but this home certainly wasn't. At 1700 sf, everything felt just right to me.

The home will be on view at other trade events:

The Harbinger Home will go on a journey just as the containers did. It will go to the Urban Land Institute next for their October show, then up to Washington DC for Ecobuild America [in December].

Private Island Blog approves:

The home is ideal for island life as it is set up for the use of solar power and rainwater recycling.

The story behind the name:

West Coast Green had a contest in the naming of the house. The winner, Gregory Schaefer, came up with "Harbinger House", saying:

'By definition, a harbinger is something which allows us to see the future, a foretelling, a symbolic event or bridge. I think we usually are aware of these in hindsight, but here, today we can clearly see the future. The Harbinger House is a model of sustainable design that needs recognition for its forward thinking vision and creativity.'

Visit the West Coast Green site for a long (55 minute) video of the assembly of the Harbinger House. Floorplans are also available.

Via email from  Alchemy Architects, we learned about 3 upcoming open houses for the

Alchemy Architects, we learned about 3 upcoming open houses for the  weeHouse.

weeHouse.

Saturday, October 11, 2008

- 10am - 5pm

- Sloansville, NY

Sunday, October 12, 2008

- 10am - 5pm

- Ulster Park, NY

As these two homes are private residences, please RSVP and get specific directions by emailing Betsy Gabler: betsy@weehouses.com.

The third open house is public:

Thursday, October 16 - Thursday, October 30, 2008

- Philadelphia, PA

- Part of A Clean Break Exhibition, and Design Philadelphia

A blog called Greenlight has some interesting news:

The Japanese electronics giant has assembled a strategic plan to start making modular homes in about three to five years that will combine green construction along with sophisticated electronics to curb energy consumption.

While the energy savings ideas are new, Panasonic "already has a construction division that makes modular homes in Japan."

Though not likely to be coming to the US anytime soon:

the U.S. could be the last market it approaches...

Contemporist looked at homes from  Modern Living in Sweden.

Modern Living in Sweden.

Inhabitat's Prefab Friday covered  BURST*008:

BURST*008:

The BURST homes ... are clearly not about affordability, but about systematizing the process of designing homes based on specific rules.

Inhabitat also wrote about the Redondo Beach house from  DeMaria Design Associates:

DeMaria Design Associates:

The home, constructed with a combination of prefabricated shipping containers and traditional buildings materials, is a stunning beachfront residence.

ColoradoBiz Magazine reports on Sidekick Homes from  Kephart Living:

Kephart Living:

Sidekick specializes in ADUs, or accessory dwelling units. They're anti-McMansions, small — sometimes tiny — living quarters built for backyards of existing homes, typically for aging relatives. Hence, they’re sometimes called "mother-in-law" or "granny" flats.

That's a great niche for modular construction.

The article included some local details:

One complication for the backyard ADU business is that zoning rules vary among municipalities and neighborhoods. ....

"They’re promoted by cities like Arvada [Colorado] as a way to help with the affordable housing issue and the issue of housing the aging population, which are both coming together pretty strongly right now," Kephart says.

In Denver, ADUs are allowed only in neighborhoods zoned for mixed use, such as Stapleton...

Other basics:

- price: $75,000 - $200,000

- size: 400 - 1160 square feet

- owner Michael Kephart launched Sidekick Homes early this spring

The best part:

They're ... pre-built and trucked from the factory to the home site with everything from the ceiling fixtures to the kitchen counters intact.

MKD has added the above video to their Web site. It shows the assembly of their mkSolaire at the museum in Chicago. Fun to watch.

There are plenty more where that came from.

Architectural Record reports:

From October 17 to 30, a temporary prefab “neighborhood” in Philadelphia will offer an optimistic view of what a revitalized city might look like in the near future. A Clean Break, curated by Minima Gallery, will be a central event of DesignPhiladelphia, an annual series of lectures, studio tours, and exhibitions organized by the Design Center at Philadelphia University.

The show will feature two actual prefabs:

Also in the exhibition:

renderings of residences designed by Gans Studio & dArchitects, Studio 804, and Interface Studio Architects ...

The exhibition is free and open to the public.

Last week, NPR covered MoMA's Home Delivery exhibition. The story shared many of the same details we've already reported. However, one new tidbit was the mention of a large prefab project going up in Brooklyn:

On a former landfill in the reedy seaboard of southern Brooklyn, where ocean breezes gently stroke the air, the sound of power tools splinters the morning silence.... the first phase of the Nehemiah Spring Creek affordable housing development.

Spring Creek looks like any construction project, built the conventional way. But the town houses lining these just-paved streets aren't actually built on site. They were trucked in, arriving at the site in almost move-in condition...

The town houses are prefabricated, manufactured miles away in a vast warehouse at the Brooklyn Navy Yard. Then they are brought here whole on a flat-bed truck at night, when they won't interfere too much with New York City traffic...

The online article and accompanying audio are worth a visit.

From a recent press release:

Michelle Kaufmann ... completes 30 homes, sees business triple over past year.

This seems noteworthy, especially considering the current state of the US housing market. Congratulations to  MKD!

MKD!

Earlier this month on her New York Times blog, Allison Arieff posted a well-argued commentary on MoMA's Home Delivery show:

The puzzling thing about "Home Delivery" is its focus on homes that you can’t actually have delivered. The exhibition is chock full of gorgeous and historically significant architectural drawings and models, but the curatorial agenda of the show is muddled.

Specifically:

...it’s hard to understand the decision to exclude from the exhibit the small but significant group of architects who are actually producing prefab homes on a significant scale today.

She mentions:

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

-

Rocio Romero

Rocio Romero

-

Resolution: 4 Architecture

Resolution: 4 Architecture

- IKEA's BoKlok

In contrast, Arieff liked the Whitney Museum's now-closed show on housing pioneer Buckminster Fuller:

Eccentric to be sure, this visionary couldn’t have been more prescient with his concerns about the way we live.... In contrast, "Home Delivery" has tons of cool stuff to look at, but it really does feel odd that a show about homes has so little to say about the experience of actually living in one.

I'm sorry that we missed that one.

Read the full post for more details; Arieff knows the field.

materialicious moved from materialicio.us to materialicious.com. They've been reposting old content and adding some new content.

Jetson Green's guest post on affordable, green prefabs sparked a few responses around the web. Treehugger's Lloyd Alter concluded:

If Jim Kunstler is right and the American suburban experiment is dead, then there will be lots of cheap labor about and prefab is pretty much dead too- it will never be competitive.

But at some point when the housing market returns and there are banks that lend money, people are going to demand the quality and consistency that comes from a factory. That's why cars aren't built in driveways.

BuildingGreen also had something to say:

Unlike Ludeman, I'm not ready to give up on prefabrication just yet. I still think there's promise in the idea of prefabricated green, especially in the mainstream and affordable housing markets. As for green modernist housing, the benefits of prefabrication may never come through for such a relatively small market.

Inhabitat's Prefab Friday looked at the Cellophane House from  KieranTimberlake Associates:

KieranTimberlake Associates:

If its ease of construction doesn’t amaze you, consider the aluminum frame and structural polycarbonate floor plates. Or the easy bolt connections that facilitated the easy assembly and the available built-in environmentally-friendly features, and then you just might be wondering if you covet the ingenuity behind these homes.

Design blog coochicoos shared some photos from his weekend visit to  Marmol Radziner's Palms House.

Marmol Radziner's Palms House.

This month's Conscious Choice, "an enlightened urban lifestyle magazine," examines Prefab 2.0 in a recent article:

Judging by magazines, museums and word of mouth, you might think we were in a prefab housing Golden Age.

You’d be wrong — but not by much. Yes, prefab housing is getting more attention than it has for decades. And yes, beautiful prefab homes are on display at museums and design exhibitions. But just because they’ve built them doesn’t mean homeowners are coming in droves. Instead, only about 100 homeowners live in prefab homes in the U.S....

(One quibble: the estimate of 100 is only true based on a narrow definition, e.g. modernist prefab built in the last few years. We take a much broader view of prefab.)

The article included several profiles from around the US:

Chicago, Illinois

Prefab is an interesting idea and like any good academic, Chris Conley wanted to put the theory to a test. So when he and his family set out to build a weekend home in Libertyville, they decided to be their own guinea pigs.

Designer: the homeowner, Chris Conley

Venice, California

The one-story house has turned out to be the home of their dreams. The house came out on time and on budget.

Designer: Jennifer Siegal of  Office of Mobile Design

Office of Mobile Design

Seattle, Washington

He was so convinced prefab was the future that he and his partner Bill Shepherd bought some land on Whidbey Island to try one out.

But if his experience is any example, prefab may not yet be ready for prime time.

Designer:  Rocio Romero

Rocio Romero

New York, New York

Logistically, they were hoping that building the house in the factory would save time and money. But it didn’t quite work out that way, says Morrow. Getting the permits and doing the finish work, like building a screened-in porch and attaching the four modules to one another, took the same amount of time as any other house.

Designer:  Resolution: 4 Architecture

Resolution: 4 Architecture

San Francisco, California

"We wanted high-quality and enduring style," says [homeowner] Haney. "What we weren't prepared for was the quality of the house. I have built several houses and this is by far the best quality home I've ever lived in. It's fabulous. When you build on-site, there's little quality control. The individual contractors are all supposed to do their jobs, but the overall aesthetic is almost left to chance. In a factory, you have quality control at every step."

Designer:  Michelle Kaufmann

Michelle Kaufmann

Read the full article for additional details.

Apartment Therapy Chicago looked at Werner Sobek's R128 and H16 homes:

These structures aren't available through a manufacturer; they're custom homes designed using lightweight, modular parts. The "prefab" part of these homes lies in their skillful engineering. R218 (shown above) is made from 100% recyclable, easy-to-assemble mortise and tenon joints and bolted joints, while the H16 is made from prefabricated architectural concrete...

And Apartment Therapy New York caught The New York Times' coverage of "high-style sheds":

The focus of the story is on the immediate gratification of prefab sheds ...

Prior to the New York Times' articles, Treehugger wrote about friggebods, or Swedish garden sheds:

Dorte Mandrup Arkitekter have designed a lovely little 100 square foot cabin/office/guest room prefab that is lovely to look at.

Inhabitat's Prefab Friday covered the Danish Easy Domes:

The dome offers individuals the opportunity to build their own high quality homes, coming with pre-built wooden sections, ready to assemble on either a concrete or timber plinth. Once on site, the dome houses take only one day to raise and seal, and for domes less than 50 square foot, no crane is needed to complete construction.

On Wednesday, The New York Times filed a pair of articles on small homes. The first, specifically covered prefab sheds:

Tiny, high-style prefabricated sheds like the Kithaus have received a great deal of attention over the last year, with admiring coverage in design blogs and magazines, and roughly four times more companies producing them now than five years ago. So far, the market is still small, though a tipping point of sorts may have been reached this year, when Design Within Reach began selling the Kithaus, along with furnishing packages to turn it into an instant office, bedroom, pool house or den.

Companies and models included in that article:

The second explained the "tiny house" phenomenon:

... spaces that are smaller than 1,000 square feet and, in some cases, smaller than 100. Tiny houses have been a fringe curiosity for a decade or more, but devotees believe the concept’s time has finally arrived.

Prefab models mentioned:

Marmol Radziner recently completed construction of their Palms House in Venice, CA. Here are the Open House dates:

Marmol Radziner recently completed construction of their Palms House in Venice, CA. Here are the Open House dates:

Click the above links to reserve a slot. Space is still available on all dates.

Event better, you can attend a special session at the house hosted by firm principal Leo Marmol, FAIA:

An interesting story from Ball State University in Muncie, Indiana:

Michael Gibson recently finished a building prototype that utilizes prefabrication techniques in a way that has never been done before....

Gibson's plan included two standard prefab walls and two experimental walls he called lattice walls that were made of plywood instead of the standard dimensional lumber, which he said wastes materials. The lattice walls also used less material because of an assembly form called nesting, in which several lightweight boards nest together in a V-shaped fashion.

"The beautiful thing about the lattice walls and how they nested together was that they used less nuts and bolts," Gibson said. "They were also very lightweight, and the pressure from the roof was pretty evenly distributed, which prevented the structure from racking."

Most of the companies we track use a small number of accepted framing techniques. Some use SIPs:

Others use traditional framing (whether wood or steel):

-

Rocio Romero

Rocio Romero

-

Marmol Radziner

Marmol Radziner

-

LivingHomes

LivingHomes

-

Alchemy Architects

Alchemy Architects

-

Empyrean International

Empyrean International

-

Hive Modular

Hive Modular

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

And a few use unique metal framing systems:

Worth noting: the plywood framing system used in the  BURST* model, currently on view at MoMA's Home Delivery show, used a similar plywood framing system.

BURST* model, currently on view at MoMA's Home Delivery show, used a similar plywood framing system.

Inhabitat's Prefab Friday looked at the Lifepod:

Escape to the beach, the mountains or the trees in San Francisco-based Kyu Che’s sustainable Lifepod. Loosely based on the traditional Mongolian ger (or ‘yurt’ as the Russian translation goes), the Lifepod is at once organic and high-tech. Built to be highly portable, the Lifepod is a fully functioning, off-the-grid mini capsule for modern nomadic living.

Shedworking reported that Alchemy Architects are considering bringing their weeHouses to the UK:

Mark Ramuz from Garden2office is talking to them about the possibility of bringing over the smallest of their buildings if there is enough interest.

A recent email from  Alchemy Architects says:

Alchemy Architects says:

We have now included more and lowered our prices! 2,000 SF weeHouses with Good Stuff are around $125/SF or less, leaving you extra coins to put into your site.

Old pricing was in the $150/SF range, so it's quite a drop. Actual pricing depends on your part of the country.

Also mentioned:

Order a weeHouse SMALL with an off-grid Solar Package before November 1, 2008 for only $99,000 [$109,000 for CA and other states west of Colorado]. Outfitted with Fusion's 720W AC Energy Kit, you only need to provide the foundation, well, and septic to have a completely finished retreat.

Higher capacity solar kits are available for larger homes. For details: FusionModular.com.

We've thoroughly enjoyed A Prefab Project which chronicles the construction of a Resolution: 4 Architecture prefab in West Virginia. Homeowner Chris more or less calls it quits in a recent post, and I can't help but be a little sad.

Granted, the home is complete, but the blog has been such a great resource for understanding the process of building a prefab.

If you haven't taken a look at the blog previously, it's definitely worth it, especially now that the long road is coming to an end.

Well, not exactly "this week", more like "the last two weeks." Here's all the news from while I was away on vacation.

Earlier this month, architecture blog Contemporist covered some minimal prefabs from Swedish company Arkitekthus:

Their goal is to bring good design to a larger market that otherwise could not afford an architect designed home.

Inhabitat's Prefab Friday looked at Travelodge's shipping container hotel in England:

The completed design uses eighty-six containers of various sizes that were retrofitted into bedrooms and bolted together onsite. The exterior has been clad and fitted with windows, thus converting the assemblage into a seamless 120-bedroom hotel.

Inhabitat also showed off the XO Mobile Structure from 70ºN Arkitektur:

... embodies an extreme of living simply - or simply living. The gorgeous prefab features a minimalist two-room construction that comes as-is and goes anywhere you please.

The Dwell blog discussed prefab sheds:

Lately, I've been coveting a Modern Cabana or Modern Shed for my personal back-40 in Los Angeles.

Treehugger cited another Dwell blog article in a post about "park models," or trailers, and their relation to prefab:

There is a vast infrastructure of trailer parks around North America that are due for change and upgrading, and a few visionary park operators are beginning to look at the market for modern.

I am on vacation all of this week, but will be returning September 1. Look for new posts then.

The Washington Post discussed MoMA's Home Delivery show earlier this week, leading with a quite provocative line:

The architect who masters prefabricated housing -- how to make homes that are well designed, mass-produced, affordable and easy to build -- may well go down in history as the Last Architect.

Got my attention, at least. The article continues with the prodding:

As a fascinating and important new Museum of Modern Art exhibition, "Home Delivery: Fabricating the Modern Dwelling," makes clear, they have mostly failed. But if anyone ever succeeds, perhaps the grand challenge of domestic architecture would be over -- time's up, pencils down.

The article makes many such observations and poses a few questions:

The paradox of the prefab dream, which began with proles in boxes, is that it lingers in the bourgeois craving for luxury goods and second houses.

And so does prefab turn out to be just another designer accessory, not so different from Louis Vuitton handbags or Prada shoes, industrial status symbols that are basically the same from unit to unit? Is it true once again that the blessings of modernism, supposedly a gift for the many, are really just a prize for the few?

Some specific thoughts on the homes in the show:

the ridiculously small confines of the Micro Compact House will [not] leave you with any desire to live there.

the System3 project ... is a compelling piece of architecture by any standard.... Stand in the System3 for a few moments, and you want to live here.

In summary:

"Home Delivery: Fabricating the Modern Dwelling" will leave you honestly conflicted, dubious about where history has brought the prefab dream. And more than ready to move into a prefab castle, just as soon as you can buy a nice plot of land and muster the down payment...

What do our readers think about The Posts's observations? Have most of prefab's early practitioners failed? Is prefab just a "prize for the few?"

While reading the full article, be sure to check out the accompanying slideshow.

From Materialicio.us, here's a useful tip for those interested in MoMA's Home Delivery exhibition:

I just went to see the show myself this past monday, and I put the best of the photos I took up on Flickr the next day. I tagged them and yesterday decided to see who else had visited and tagged their photos with “Home Delivery”. I was pleasantly surprised to see many other photos on Flickr. A great way to get a photo tour if you can’t make it to the show.

The link: Flickr Home Delivery search

Witold Rybczynski filed a slideshow report from MoMA's Home Delivery show. In his usually candid style, he gives his impressions of the show, inside and out:

Prefabricated houses have remained an elusive goal for architects, and the MoMA show is a stylish litany of second-place finishers, also-rans, if-onlys, and downright losers.

I'd dare to say that just being included in the MoMA show makes each of the featured projects a first-place, upright winner, but maybe that's just me. Anyway, back to Witold:

After considering some 500 firms, the museum chose younger, lesser-known architects, and the range of solutions demonstrates both a sense of enthusiasm and a variety of novel prefabrication technologies.

He shares his thoughts on the  BURST*008:

BURST*008:

The rather crudely built structure looks out of place here—or, I suspect, anywhere.

The  System3:

System3:

most people's idea of contemporary prefabrication: It's elegant, stylish, and rather austere.

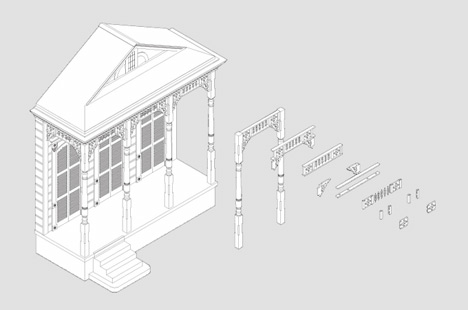

Larry Sass's Instant House:

an ingenious and very complicated answer to the wrong question. ... The laser-cut decorative fretwork on the porch is nice, though.

The  m-ch:

m-ch:

Nothing revolutionary here, but a very nicely designed package.

(Though he suggests buying an Airstream trailer instead.)

And the  Cellophane House:

Cellophane House:

The design, fabrication, and construction are seamlessly integrated, and the various pieces are automatically ordered from the fabricator to suit the design as it is entered into the architect's computer. If there is a Next Big Idea in prefabrication, this may be it.

For the rest of Rybczynski's thoughts and some great photos, check out the whole slideshow at Slate.

The Christian Science Monitor took a look at modular homes last week, focusing on the green qualities:

This summer, two exhibitions of modular houses – at Chicago’s Museum of Science and Industry (MSI) and New York’s Museum of Modern Art (MoMA) – are putting a spotlight on how off-site building techniques can shrink the carbon footprint of a new house.

The article cites a number of reasons why building in the factory is a good idea:

- finish construction usually takes a few weeks, not months, saving energy by requiring fewer trips to the job site by construction workers

- by building indoors, workers can also more easily make sure that energy-saving features like insulation are carefully and properly installed for maximum effectiveness

- individual home-building companies may not have the resources to keep current on the latest "high-performance building" techniques ... but modular homes can have state-of-the-art environmental design built into them at the factory

The companies mentioned in the article:

-

KieranTimberlake Associates

KieranTimberlake Associates

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

-

HOM Escape in Style

HOM Escape in Style

- Envision Prefab

- Cardinal Homes

Read the complete article for details.

I was away this weekend, so here's last week's prefab news a bit late. (Posted Tuesday, but dated Saturday in line with our "This week" series.)

Inhabitat's Prefab Friday looked at  Marmol Radziner's new Rincon 5:

Marmol Radziner's new Rincon 5:

The unit was recently showcased in a Los Angeles event that explored its possibilities as a guest house, yoga studio, and home office. Want to make your new guest bedroom a Rincon 5? The basic unit costs $223,000 to be built, delivered and installed, plus the price of whichever upgrades you think your guests will appreciate most.

Materialicio.us noted that the price of the OMD showhouse in Venice has been reduced. The home (without the lot) was originally listed at $295,000, and then reduced to $259,000. Now:

reduced to $175,000

This year's West Coast Green features a new Showhouse built of containers:

At its core, the 1,700 sqft two-story home will be made of reused shipping containers, which will make construction, in any environment, sustainable, fast, and safe.

Being built right on the tradeshow floor, the home will open to a series of outdoor living spaces and decks, showcasing a dramatic outdoor kitchen ... and a stunning garden of native and naturalized plants and mature olive trees.

The stats:

- 1,700 sf

- 2 bedrooms

- 2 bathrooms

- 2 stories

Jetson Green likes it:

It's a 1700 sf container home, but you probably can't tell just by looking. Sustainability will be number one, with GreenPoint and LEED certification in the plans. Plus, it seems that ecofabulous will be doing the interior design work, so the home, you can believe, will be modish, posh, and green.

Until August 18, you have the opportunity to come up with a name:

Name the Showhouse!

We’ll pick the top submissions, and post them for everyone to vote on.

Whatever name gets the most votes, wins!

We will announce the winning name on September 1st

This year's West Coast Green building conference and expo comes to San Jose, California at the end of September:

You’ll find over 380 exhibitors showcasing the latest in resource-efficiency among a stunning array of green and healthy building products. Over 100 experts and visionary leaders will be presenting their latest developments, insights, and inspiration at the expanding frontiers of the field.

While there aren't many prefab-specific agenda items worth noting, the conference's educational agenda includes a presentation by  Michelle Kaufmann on "The Art of Mass Customization".

Michelle Kaufmann on "The Art of Mass Customization".

The long list of presenters includes Allison Arieff, former editor of Dwell magazine, and even Al Gore.

The show features a Showhouse built of containers; we'll cover that tomorrow.

Michelle Kaufmann

Michelle Kaufmann

MSNBC's Virtual Lifestyles visited the  mkSolaire in Chicago and filed the above video report. Look for:

mkSolaire in Chicago and filed the above video report. Look for:

- explanations of the home's green features

- an interview with Michelle Kaufmann

- a quick montage of the home's assembly

- various views inside and out

- a talking plant!

The price mentioned for the home: $450,000.

The Chicago Tribune visited  Michelle Kaufmann's

Michelle Kaufmann's  mkSolaire exhibit last week:

mkSolaire exhibit last week:

everything in and about the 2,500-square-foot home on exhibit just outside of the Museum of Science and Industry in Chicago has been designed to show the public how easy it can be to incorporate environmental sustainability into their own abodes.

Michelle Kaufmann commented on her hopes for the exhibit:

"We tried to look for ideas in every choice that we make in our homes ... hoping that everyone who goes through it will be inspired to make some change on some level.... Some people will walk away and want to do an entire new home, or some people will think when they go for their towels next and go for organic linens."

Some of the many features of the home:

- half the energy of traditional homes

- a third of the water of traditional homes

- water from the bathroom sink is diverted to the toilet

- a bicycle in the children's bedroom must be pedaled for 30 minutes to charge a battery to power video games

Interesting:

Visitors receive a resource guide that tells about the function of each feature, how they're assembled and where they can be purchased.

e-OCULUS, the blog for the New York chapter of the American Institute of Architects, criticized MoMA's Home Delivery exhibition:

Even though digital fabrication is interesting, I believe there is so much more that goes into prefab housing today than mass production. The eras represented in the exhibition are coming together to create contemporary prefabrication that exists out of necessity, invention, experimentation, as well as digital design. If MoMA had chosen to include examples of buildings that are built, or at least in planning phases ... the exhibition would have more relevance and urgency needed to put the many current prefab ideas into production.

DVICE, a blog from SciFi.com, shared some favorites from the show.

Inhabitat had a double Prefab Friday. First, they linked to ScribeMedia's video from MoMA, seen above: