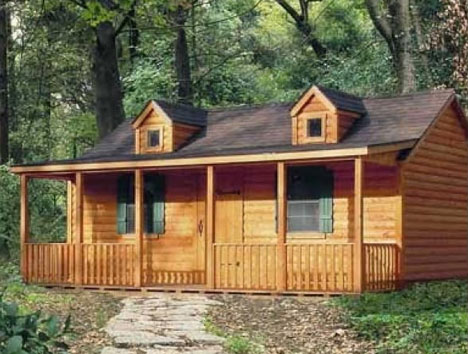

From a recent press release about  Spirit Cabins:

Spirit Cabins:

Don and Kristie Kinsey know firsthand the devastation a hurricane can cause. When Hurricane Katrina demolished their house in 2005, they decided to invest their insurance money in a home that would withstand future storms. After extensive research, the Kinseys chose the Boulder, Colorado-based company Spirit Cabins...The Kinseys were even more pleased with their decision after Hurricane Ike ripped through their Bay St. Louis, Mississippi neighborhood, destroying the area. Their home had survived fully intact.

More about the company:

Spirit Cabins combines old world craftsmanship ... with modern production technology in our state-of-the-art facility to produce fully assembled modular log homes and cabins... [They] deliver on-site nationwide completed modules customized to your needs that require little finishing work.

They offer three disctinct product lines:

And even furniture.

Other interesting pages on the company's website:

- the modular advantage

- a discussion of the difference between modular and manufactured homes.

Yesterday Jetson Green featured a long guest post by Chad Ludeman, President of postgreen: Prefab is Not The Answer to Affordable, Modern & Green Homes.

First, we will look at the prefab industry and try to dispel some of the myths that have arisen around it.

Our take: interesting points, but mostly reduces to his opinion (or very narrow facts). Several points are widely debated in the industry; others are clearly "straw man" arguments, not to be taken seriously.

Second, we will take a quick look at how the housing industry may be able to learn from both prefab and site-built homes to create a hybrid approach that will provide a better, more accessible solution to the home buyer and hopefully reduce the barrier of entry to modern, green, and unique residences.

Plenty of good ideas, but nothing stands out as new. There are lots of companies tackling various approaches to "prefab", ranging from 100% factory built to minor variations on site-built.

If you see something new and important that we missed, please add a comment!

Here's a unique hybrid wall panel, sort of half SIP, half straw bale:

The Enviro Board panels offer a superior building product that is easy to handle and assemble. Today's Enviro Board Panels are solid "concrete like" fiber panels comprised of highly compressed straw fibers. Through the Enviro Board technology, panels are extruded through the mill in a continual process, covered with a durable waterproof paper membrane, cut to desired lengths and end-capped. Panel density and thickness can also be adjusted.The Enviro Board panel replaces conventional and traditional building materials, such as drywall, thermal insulation, exterior moisture barrier (typically tar paper) and exterior plywood. In addition, because of its 32" width, using Enviro Board panels requires 50% less studs and eliminates unnecessary expenses in the form of materials and labor needed to assemble the materials.

From YouTube:

(Hat tip: Materialicio.us)

While visiting the LV Home Fans Yahoo! group the other day, I happened upon a site I hadn't seen before, Secret Fortress Hideout:

This blog documents the progress of our super-cool, pre-fab home "somewhere" in the wilds of Northwest Arkansas. Rocio Romero designed the home, model LVL, and incorporated our custom modifications.

Recent posts have covered insulation, lighting design, and construction delays:

A few critical path items jumped the track and will push us back about a week.

The stainless kitchen cabinets we ordered from Lasertron will be delayed due to an email mixup.

The heat won't be connected for two weeks, which delays the floor installation.

We found out cultured marble won't work for the tub or bathroom sinks and devised a Plan B (Neptune Zen Soaker Tub and custom-fabricated under-mount stainless trough sinks).

And, last, but not least, the company Don scheduled to prime the drywall bumped us a week.

I guess these things happen in building. It's just wild that they all happened in the last two days.

Like A Prefab Project, Secret Fortress Hideout provides a great first-hand look at the construction of a prefab home.

I came across ModularHomeChoice.com while perusing some news the other day:

This website is for those interested in purchasing a modular home or those considering one and wishing to learn more about them. I will share my experiences and lessons learned while acting as the general contractor on my modular home in the St. Louis, Missouri area.When researching modular homes, I found a lot of information supplied by builders or sales agents of modular homes. I am trying to add another perspective to that - that of someone purchasing a modular home as well as being heavily involved in the planning and scheduling of the project.

Sections of the site include:

• background information

• a list of modular builders by state

• financing

• lessons learned

• pictures of all stages of the process

The site is barebones, but informative.

The Virginia Gazette reports:

Ginger Crapse has the answer to affordable housing. “Build modular,” she said....“The perception is that they are glorified trailers,” she continued. “The inspector freaked out. I had to prove it’s modular. He said, ‘It can’t be. It doesn’t look like a modular house.’ People think modulars have to be perfectly rectangular. They see the porch and think that it can’t be modular....”

The ongoing affordable housing debate drives her nuts. “Every time I read this in the paper, I go epileptic,” she said. “They whine, ‘There’s no way to build a house for $110,000.’ There’s no reason we can’t get young families in affordable housing in Williamsburg. We are going to have problems getting teachers, firefighters, police and county employees.... “You can build and at a reasonable price.”

We've previously discussed  Empyrean International in relation to the modernist

Empyrean International in relation to the modernist  NextHouse. Empyrean also offers two other styles:

NextHouse. Empyrean also offers two other styles:

Deck House and Acorn both feature open plans, walls of glass, and soaring volume spaces. Both are custom designed for the customer and the site.The Deck House product features post and beam construction, with exposed Douglas fir beams, wooden ceilings, mahogany windows and trim work....The gently sloping roofs of Deck House feature large overhangs that often give the house a very Prairie or Craftsman style appearance.

Acorns are modified post and beam houses, but most of the structure is not exposed. Featuring expansive walls of Pella windows, steep roofs, and traditional interior trim themes; the interior surfaces in an Acorn are more often painted for a sparkling interior. Acorn exteriors draw on the best of American architectural traditions, updated with superb contemporary detailing.....

The typical price range of both brands is $200 - $250 per square foot.

Empyrean designs each house individually; homeowners can choose to modify an existing floorplan or start from scratch.

The company has been building prefabs since the 1960's. From the Empyrean site:

Deck House, Inc., was founded in 1959 by William Berkes, a graduate of Harvard University School of Design. Having pioneered other building systems, he founded Deck House, Inc. in order to provide top quality post and beam houses to upscale professional families...Acorn Structures was founded in 1947 by MIT architect, John Bemis, another pioneer in the science of pre-engineering technology and custom design. As a renowned leader in energy conservation and active solar designs, the Acorn product become widely recognized in the 1980's as a "thinking person's" custom home, with the company's architecture relating to several traditional American architectural idioms, while still being devoted to energy efficient design...

In 1995, Deck House, Inc. acquired Acorn, and the two companies consolidated their manufacturing and corporate facilities into a combined 150,000 square foot facility.

The National Association of Manufacturers has a pretty nifty series of blog posts and accompanying videos of "stuff being made". This week, they focus on Excel Modular Homes of Liverpool Pennsylvania:

Ed Langley, the company's president and CEO, gives us a tour of the operations starting with sales and moving through design and construction....Lots of construction techniques and philosophies that were new to us. And, it really is a good website with very detailed information -- videos of a modular home being "set," i.e., put in place, here, for example. The home goes up in hours!

Visit the original post for the link to the video. It's long, but shows many details of the modular home manufacturing process.

In August, Witold Rybczynski's skeptical take on prefab appeared in the form of a slideshow on Slate. We covered it, and disagreed. One thing we missed: he also made NPR.

The four minute interview reiterates much of the essay, but is worth a listen.

This video has been getting a lot of attention; it has 739 Diggs and counting.

The company is known as MasterFit in the US and MetalFit in Japan. However, the only website we can find for the company is the Japanese site. (Google translation)

Treehugger saw the system a couple years back:

"The components of the house are actually numbered, and are constructed as you would a piece of kit furniture. Materials cost 10-20% more than those for conventional framing, but the cost is offset by reduced labor expense..."

The "no tools" approach is similar to the  kitHAUS system, except with wood members. Both systems enable relatively unskilled laborers to frame an entire home.

kitHAUS system, except with wood members. Both systems enable relatively unskilled laborers to frame an entire home.

A while back, a commenter on Inhabitat posed what seemed like a radical idea:

"It occurs to me that the factory could be brought to the jobsite with a modification of this method of construction. Perhaps we need to borrow the best method from factory and on-the-job techniques, instead of thinking either-or. For example, why not bring a semi truck that opens out into an on-the-job manufacturing construction unit."

According to the Globe and Mail, a developer in Ontario apparently had the same thought:

'The chandeliers are hanging, the tiles are grouted, the hardwood is shined up,' says Ron Cauchi, president of Mattamy's Stelumar operation....

Anybody who purchases a new house from a builder wants two things: a sturdy structure and a predictable closing date. Legions of buyers have suffered through problems with both.

For years, Mattamy has been looking for a way to improve the quality of the houses it builds and the reliability of move-in dates by transferring some parts of the construction process to the factory floor....

The longest distance any house will travel is about one kilometre, Mr. Cauchi says.

He expects the project to be complete in about four years, at which point the factory will be taken apart and re-erected somewhere else."

Seems like the best of both worlds: factory-built on site!

The Dwell on Design conference is this weekend in San Francisco.

We won't be there, but here's who will:

•  Alchemy Architects

Alchemy Architects

•  EcoSteel, aka EcoContempo

EcoSteel, aka EcoContempo

•  Empyrean International

Empyrean International

•  H-Haus

H-Haus

•  Hive Modular

Hive Modular

•  Michelle Kaufmann

Michelle Kaufmann

•  kitHAUS

kitHAUS

•  LivingHomes

LivingHomes

•  Modern Cabana

Modern Cabana

•  Rocio Romero Homes

Rocio Romero Homes

We heard from Alchemy Architects:

"Alchemy Architects will be at Dwell on Design 2007 with a weeHouse to 'tour'. Amazing, but we had a CA client who's weeHouse is just being finished...so it'll stop in San Fran on its way to San Diego. It's a very exciting opportunity for people who are interested in a weeHouse to see a weeHouse. We'll be in the outdoor, prefab section."

We know these vendors won't be attending:

•  CleverHomes

CleverHomes

•  v2world

v2world

Some prefab-specific events that will be worth checking out:

• September 15 and 16, 2:45 - 3:15: "Prefab Discussion Panel" hosted by Michael Sylvester of fabprefab.com

• September 15, 2:00 - 2:30: "The Process Behind Prefab:The Design and Production of Green Modular Homes" with Jared Levy and Jason Davis of  Marmol Radziner Prefab

Marmol Radziner Prefab

• September 15, 3:30 - 4:00: "Creating the First LEED Platinum Home" with Steve Glenn of  LivingHomes

LivingHomes

Yesterday we covered a slideshow essay at Slate that criticized the current "prefab fad." Rybczynski has a 3 part indictment:

"unpopular, expensive and divorced from industrial production".We're not sure whether he's paying attention.

As for "unpopular", Modernist homes (prefab or otherwise) are aimed at a specific audience:

"Where are all these people who live in cool lofts and spaces in the city supposed to go when they move to the country? They certainly don't want to go live in a colonial-style house." (Robert Luntz of Resolution: 4, quoted in Builder Online)

It's unlikely that modernist prefab will sweep away the dominant preference for traditional homes. But it could easily become a profitable (self-sustaining) niche. Our favorite example is the one that we (Peter and Scott) are using to create and edit this post: the Macintosh still has less than 10% overall market share but represents a thriving business that continues to dominate several niche markets.

Prefab doesn't just mean modernist, e.g.  Hive Modular offers a (mostly) traditional facade,

Hive Modular offers a (mostly) traditional facade,  Empyrean's Deck House and Acorn are classic "post and beam", and the "traditional" modular housing industry is growing.

Empyrean's Deck House and Acorn are classic "post and beam", and the "traditional" modular housing industry is growing.

The current crop of prefab architects want to make "good design" more affordable.

"Most architects working in prefab are trying to create standard designs, to reduce the cost and risk to the client, and bring the services of talented architects to smaller houses." (Lloyd Alter on Treehugger, quoted in May)

"While her first customers tended to fit the stereotype of the Prius-driving, NPR-listening eco-consumer, Kaufmann is increasingly fielding inquiries from people who just want an attractive, affordable house." (From an article on Michelle Kaufmann in July.)

Last point: prefab is not "divorced from industrial production". Many of the companies we cover have built their own factories and most others are working closely with existing factories.

Has the prefab industry achieved its goals? No. Is it headed in the right direction? We think so.

Earlier this month, Slate posted a slide show essay by Witold Rybczynski on "The Prefab Fad." The essay and slide show cover a number of modernist prefabs, arguing that "the current vogue for prefabs is more about industrial chic than affordability."

Rybczynski's says that "modern architecture is unpopular, expensive and divorced from industrial production. That is why whenever it has tried to extend its field to include the territory of the prefabricated house it has failed and been forced to retreat." He predicts that "the current generation of Modernist prefabs is unlikely to fare any better."

Lloyd Alter of Treehugger says "I hope he is wrong."

We think he is. For details, please tune in tomorrow!

As we've reported before, prefab is not just for homes. Business Week recently covered an interesting new hotel in Amsterdam:

The Cubi, a pre-assembled, 74-square-foot cube-shaped living area, is the focal point of each room. Despite the seemingly cramped quarters, each Cubi is both self-contained and luxuriously appointed with Swedish Hästens beds, flat-screen TVs, high-speed Internet access, and a small work station. The bathrooms boast a rain shower and Philippe Starck fixtures....

The Cubi can be placed and hooked up within a few hours. Which means Qbic is a near-instant hotel."

The  perrinepod is a prefab product out of Australia made from a precast concrete shell. While the pods are heavy, assembly takes just three days and the pods are engineered to stack up to 30 units high.

perrinepod is a prefab product out of Australia made from a precast concrete shell. While the pods are heavy, assembly takes just three days and the pods are engineered to stack up to 30 units high.

PerthNow reported on the house last week:

"Here's something for the 'I want it now' generation - a house that can be erected in three days. But this is no flimsy, mail order, do-it-yourself number, the Perrinepod is made from pre-cast, pre-stressed and tensioned concrete and is cyclone and earthquake proof."Worth noting:

"With more than 100 orders on his books already, including some from resorts, developers and other corporate groups, Perrine is quite confident the pod will take off."

Inhabitat was impressed.

Materialicio.us was too.

Last week, CNET posted a photo gallery of a modular home with solar electric, solar hot water and other green features:

A key design element of this green building is its metal roof, which on first thought may not seem energy-efficient. After all, metal absorbs heat, and air conditioners consume a lot of electricity.

But PowerHouse's metal roof serves two specific purposes: heating the house in the cold season and generating electricity. Builders run plastic water tubes under the roof. The water is heated by the sun and distributed through the house to supply hot water and warm the house. The house also has solar electric panels to generate electricity during the day....

The company expects the two-unit project, begun in late June, to be done by the end of August."

"Power Pod Can Reduce Energy Costs Up to 80%. And that's pretty incredible"

Treehugger is a fan:

"The modular green prefab biz is full of difficult choices and tradeoffs. The Powerhouse people appear to have thought about them carefully here. Small, green, just drop it in place, what could be better?"

'Prefab' can mean more than the modernist prefabs featured in Dwell and other design magazines, as Grace at Apartment Therapy LA found out:

"When friends of mine told me that they were building a prefab house on their lot on the outskirts of San Diego, I was expecting an offshoot of the Glide House. Imagine my surprise when they sent me a photo of their rustic cedar mansion courtesy of Lindal..."

According to the Lindal Cedar Homes FAQ:

Many homeowners rebuilding after Hurricane Katrina are turning to modular construction:

'The labor is all done in a factory, and this house is really well built,' she said. 'The whole roof is bolted down. And I've got the fattest pilings I could find. If it doesn't hold up in the next hurricane, I'm moving back to Texas....'"

"Modular or system-built homes are constructed in a factory and shipped by truck in sections called modules or boxes. There can be two, four, six or more modules, depending on the size of the house, Stewart said. The modules are lifted by crane and placed on the pilings or foundation -- and that takes a day. The modules are about 90 percent complete when shipped and include all the walls, flooring, ceilings, stairs, carpet, and wall finishes...."

Walt Bolton, an engineer at B.E.S. Construction:

"The quality, the price and the quick turnaround drew Bolton to modular building. 'We have great local subcontractors, but when you build a product in a plant, the consistency is much greater and you don't have to worry about the temperature, wind or rain.'"

Read the whole article for more details about why people are choosing modular.

A 23-unit modular development is rising in Grand Haven Township, Michigan:

The 11 duplex-style condo buildings will include composite fieldstone on the building's exterior....

They will be assembled on the site, along with garages and sunrooms. Each condo will have an inspection sheet when they're built in Indiana that will be completed by Michigan inspectors."

Quon Modular is a semi-custom prefab system from Australia. Each room is a (mostly) self-contained module, measuring 5 m x 3.1 m (16 ft x 10 ft). Buy exactly what you need placed side-by-side, stacked, or each by itself.

Quon Modular is a semi-custom prefab system from Australia. Each room is a (mostly) self-contained module, measuring 5 m x 3.1 m (16 ft x 10 ft). Buy exactly what you need placed side-by-side, stacked, or each by itself.

Room options and prices:

•  Bedroom, ~$31,000

Bedroom, ~$31,000

•  Kitchen, ~$48,000

Kitchen, ~$48,000

•  Bathroom, ~$40,000

Bathroom, ~$40,000

•  Master Bedroom, ~$32,000

Master Bedroom, ~$32,000

•  Multi-purpose, ~$28,000

Multi-purpose, ~$28,000

Materialicio.us loves the concept:

"For me, this is the simplest, most efficient system yet devised for a customized, prefabricated house. Design your house using their standard components, place the order, and ten weeks later it's delivered."

Few prefabs offer such a flexible approach. The  weeHouse series from

weeHouse series from  Alchemy Architects allows for the addition of specialized modules, such as the sleepTight, but their modules vary in size.

Alchemy Architects allows for the addition of specialized modules, such as the sleepTight, but their modules vary in size.  v2world was offering a similar product in their

v2world was offering a similar product in their  v2shell, but last we heard, they were reworking their product line.

v2shell, but last we heard, they were reworking their product line.

(More coverage: Treehugger)

The folks over at A Prefab Project are having an exciting time, with the delivery and set of their prefab home.

A post on Friday announced the successful arrival of the module on site:

"After many hours on the road and seven flat tires, our house arrived at the site in WV a little after 6:30 Wednesday evening."

Luckily the module arrived in good condition with little damage:

"Well, good news is the house made it fine. No real issues - some minor drywall cracking, a couple of window locks popped during travel that will need to be replaced (not sure exactly what will need to be replaced - Simplex will let me know). Structurally, the house came through great. Window panes are all intact, the loose materials that shipped inside the box didn't do any damage, and no water got in."

On Monday, the house was finally set:

"No attempt at a witty title - I'm too tired. But everything went great. The set was a breeze. Only really took about fifteen minutes to actually lift, move and set the box (and about six hours to set up and break down the crane)."

Homeowner Chris also gave a detailed and useful look at the foundation work that occurred prior to the module's arrival.

Steve Kieran's  Loblolly House takes flat-pak prefab to a whole new level. Kieran's firm

Loblolly House takes flat-pak prefab to a whole new level. Kieran's firm  KieranTimberlake created a series of panels and structure that integrate all of the home's mechanical systems:

KieranTimberlake created a series of panels and structure that integrate all of the home's mechanical systems:

The assembly process begins with off-site fabricated floor and ceiling panels, termed 'smart cartridges.' They distribute radiant heating, hot and cold water, waste water, ventilation, and electricity through the house. Fully integrated bathroom and mechanical room modules are lifted into position. Exterior wall panels containing structure, insulation, windows, interior finishes and the exterior wood rain screen complete the cladding."

Hive Modular,

Hive Modular,  Marmol Radziner, and

Marmol Radziner, and  Alchemy Architects, integrate utilities into multi-room modules that are shipped to the site near-complete. But the companies delivering flat-packed products, like the

Alchemy Architects, integrate utilities into multi-room modules that are shipped to the site near-complete. But the companies delivering flat-packed products, like the  LV Series homes from

LV Series homes from  Rocio Romero, require on-site work to incorporate utilities and finishes. The SIPs or stud-framed panels they ship generally incorporate little more than structure and insulation.

Rocio Romero, require on-site work to incorporate utilities and finishes. The SIPs or stud-framed panels they ship generally incorporate little more than structure and insulation.

For the Loblolly House, this complete prefabrication was necessary to avoid large amounts of work on the sensitive site. The process even works in reverse:

"Just as the components may be assembled at the site swiftly with a wrench, so may they be disassembled swiftly, and most importantly, whole....It is a vision in which our architecture, even as it is disassembled at some unknown moment, can be relocated and reassembled in new ways from reclaimed parts."

Complementing the designs of Ray Kappe and David Hertz,  LivingHomes plans to sell homes based on the system used in the Loblolly House. Also worth noting: Bosch produces the structural frame used for the Loblolly House and the TK iT House.

LivingHomes plans to sell homes based on the system used in the Loblolly House. Also worth noting: Bosch produces the structural frame used for the Loblolly House and the TK iT House.

(Hat tip: Philly.com)

Earlier coverage: Wired article on Plug and Play Construction (January); Architectural Record (April).

If your goal is to reduce the amount of on-site work to an absolute minimum, a houseboat delivers the ultimate in pre-fabricated housing. No earth movers or cement trucks required. Bonus points if the factory is on the water: the width of the flatbed truck no longer matters. Case in point: Modern Marine Homes in Sweden.

"Modern Marine Homes was established in 2002 from a vision of waterside living without compromising the demands expected from a modern villa. The result was [Villa Näckros], a new concept within marine living. A home with modern design characteristics and carefully considered construction."

Architecture firm Strindberg Arkitektur designed the original Villa Näckros, one of two models now available, and formed Modern Marine Homes to sell and produce the product:

"A residence for a client grew to an industrial project, with leading words as: sustainability, low maintenance, development of materials and building, care for the environment, low energy costs, identity....A comfortable living and a lay-out that gives you the optimal feeling of the closeness to the water."

Kalmar, Sweden has even developed a pilot program with Modern Marine Homes for living on the water:

"This unique work has led to the development of properties for living on the water — a floating residential project in the centre of town with the opportunity to leasehold or freehold [own]. The project will be a guide for the future design and construction of floating living in Sweden."

The house was awarded "Building of the Year 2003" by the Swiss Construction Industry. The homes are not available in the U.S.

(Hat tips: CubeMe, Treehugger, Materialicio.us, cool boom, and Arkinetia have all shared their thoughts.)

Hive Modular invites the public to "experience the set process" of one of their

Hive Modular invites the public to "experience the set process" of one of their  B-Line homes in St. Paul, Minnesota later this week. Details below.

B-Line homes in St. Paul, Minnesota later this week. Details below.

The BRE Group is a British "research, consultancy, training, testing and certification organisation delivering sustainability and innovation across the built environment and beyond." They reported this week on the Osbourne demonstration house, built from SIPs:

The house needs two thirds less energy for heating and cooling than a house constructed to 2006 Building Regulations."

• a zinc and slate clad cassette roof that requires no trusses or rafters

• off-site manufactured bathroom pod and door sets

• a plug-together wiring system

• timber I-beam floor joists.

Architecture.mnp posted some unique views of the Maison Tropicale in the rain, plus a nice interior shot.

Similar to SIPs, the Thermomass Building Insulation System consists of two layers of modified concrete with styrofoam between. The system is flexible enough to be "used in site-cast tilt-up, plant precast, modular precast, tunnel form and poured-in-place concrete panels and walls." The site-cast tilt-up method moves the process out of the factory, allowing rapid construction on site.

Architects John Dwyer & Jeff Gallo selected the energy-efficient Thermomass walls to help their 5IVE house achieve LEED Platinum certification:

"Using a technology developed by DOW, the walls will act as a thermal mass giving them a rating of R-30. By employing prefabrication, we were also able to control the quality of the finish on the concrete."

The walls for the 5IVE home are being produced by a company called Forecast Concrete. The benefits of factory precast concrete walls include:

• added precision

• controlled environment

• no form lines

• high strength concrete

The company says that the process is adaptable for any style and size of home.

(Hat tips: Future House made a quick post on June 2, Lloyd Alter of TreeHugger added some detail on June 6, Preston Koerner waxed enthusiastic at Jetson Green on June 7.)

Last week's Prefab Friday on Inhabitat covered an interesting project in the UK:

The Container City™ system uses shipping containers linked together to provide high strength, prefabricated steel modules that can be combined to create a wide variety of building shapes and adapted to suit most planning or end user needs.

This modular technology enables construction times and cost to be reduced by up to half that of traditional building techniques while remaining significantly more environmentally friendly."

Since then, the system has been used for residential, commercial and educational buildings. Projects range from the 7 container Music Studio to the 73 container Riverside Building.

Brand Avenue covered the system a while back:

"I appreciate how they acknowledge temporality: implicit in their no-nonsense construction, and the light ways they touch the ground, is the idea that the site can and will be cleared someday, and something else will take their place. In this way, they interact rather respectfully with context..."

YouTube has a clip from the History Channel's Modern Marvels about the home:

LiveModern is a website for "anyone interested in modern and sustainable design for housing products and services."  EcoSteel, aka EcoContempo, contributes content to the site. Especially worth a look is the construction blog by architect

EcoSteel, aka EcoContempo, contributes content to the site. Especially worth a look is the construction blog by architect  Greg La Vardera:

Greg La Vardera:

"Our blog is for tracking the development of new Modern House designs which are available at our catalog house plan site lamidesign.com/plans. We also cover the prefab house products we work on such as EcoContempo, EcoSteel, custom modular, and IBU container based housing."

The blog covers the variety of projects, detailing developments in the ongoing planning and construction of each. A recent post focused on a project in New Mexico, including photos of the site and renderings of the structures:

"The project consists of a trio of buildings - a residence, a garage/shop, and an observatory structure. Yes! That's right. More detail about that later. The three structures are located in proximity to each other at one corner of the site."

At the Vermont Plat House, interior finishes are going in:

"The owner moves in to the house in a matter of days. No doubt there will be more loose ends, but we will see it almost done very soon."An earlier post on the same house had some great exterior shots.

Other projects, like the Virginia Plat House, or the Colorado Plat House just have photos of the site.

Greg also covers other projects his firm,  LaMi Design, is working on. He recently wrote about a competition entry for a multi-unit building composed of a number of single bedroom container homes:

LaMi Design, is working on. He recently wrote about a competition entry for a multi-unit building composed of a number of single bedroom container homes:

"The proposal was for a student housing village composed of a series of these [stacked] IBU structures. As the competition was being held in concert with a conference on green building, the student housing was proposed as a test bed for new sustainable energy and building systems. It was proposed that the units serve the Engineering school allowing for the students to live in and work at innovating and optimizing the new systems being designed at the school."

Glossary: IBU (Inter-modal Building Units) - Greg La Vardera's name for container housing

I've been reading more about Yurts, and I'm beginning to be won over.

The Yurt Foundation lays out the key advantages:

Yurts are special because they are portable. Central Asian nomads put their gers up in an hour or less. Modern canvas yurts can be set up in a day. To have a shelter that can be put up quickly and then taken down and moved as one's situation changes is a distinct advantage in our transient culture."

Wikipedia includes some great photos of traditional Mongolian yurts. This French company has even more photos showing the traditional process for making yurts by hand.

Treehugger reported on a BBC story about the  micro compact home we've mentioned a couple times before. The BBC report includes a video, and some insight into the home's design:

micro compact home we've mentioned a couple times before. The BBC report includes a video, and some insight into the home's design:

"It's a very tranquil place but at the same time it's a bit of an adventure - there's always something to slide out or under, pull down, tuck away, generally fiddle with, if only out of the need for space. To live here you have to be ordered: to do one thing, you have to finish another first and put it away. And that may be my and other compact-livers' downfall."

The Maison Tropicale sale made a couple more headlines. An AP story about the sale showed up on quite a few sites, like ABC Money UK:

"Its last owner, Eric Touchaleaume, a French antiques dealer, has said he plans to use the sale proceeds to finance a Prouve museum that will travel inside another Maison Tropicale."NY Arts Magazine explained the original use for the prefab homes:

"Prouve's aluminum and steel home was designed for French colonists living in Brazzaville, now the capital of the Republic of the Congo."

Future House Now likes A Prefab Project as much as I do, especially the site's detailed budget page:

"It's been recently updated, and gives a lot of detail, the kind of detail you don't get from glossy magazine articles."

Apartment Therapy eyes  V2world's

V2world's  V2flat:

V2flat:

"They say it has no geographic limitations. So, we say set it up for semi-outdoor summer living anywhere."

AOL Money & Finance has posted a slide show highlighting a new book called Prefabulous. Author Sheri Koones explores a number of prefab building methods, from steel frames to large modules. The slideshow includes a variety of in-progress shots of large, custom-designed prefabs from:

• Hearthstone, Inc.

• American Timbercraft

• Sterling Building Systems

• Excalibur Steel Structures

The book was published in March 2007 by Taunton Press, which some describe as the "the leading publisher in the house and home category". In addition to magazines such as Fine Homebuilding and Fine Woodworking, they offer a whole series of books on home building and design.

Sheri Koones' previous books include Modular Mansions, House About It?, and From Sand Castles to Dream Houses.

Other coverage of Prefabulous around the blogosphere:

• Avenue A comments on prefab entering the mainstream.

• Momoy mentions the book in a discussion of "kit homes" escaping negative preconceived notions.

Elsewhere on the web:

• The Reno Gazette Journal's Robert Bruss explains that the book changed his mind about prefab homes.

• Realty Times columnist Blanche Evans provides excerpts froman interview with the author and some additional modular/prefab links.

The publisher's site includes an overview and a minimal Table of Contents.

I've really been enjoying the posts on A Prefab Project. Homeowners Chris and Sarah track the construction of their prefab home, designed by  Resolution: 4 Architecture.

Resolution: 4 Architecture.

One of the downsides of the modular building method is that modules are limited to a size that fits on a flatbed truck. Chris offers some perspective after a visit to the factory:

"When we were first looking around at the different prefab options, we had no real perspective on what 14' wide or 16' wide would be like for the whole length of a house - those are both obviously fine dimensions for a single room, but how does it feel to have a whole house fit into that width?...yesterday it was reassuring to actually stand in ours and feel how open and comfortable the space is..."

Resolution 4's 16' module width is fairly typical, e.g.

Hive Modular: 16'

Hive Modular: 16'

Alchemy Architects: 14'

Alchemy Architects: 14'

OMD: 12' - 14'

OMD: 12' - 14'

Marmol Radziner: 12'

Marmol Radziner: 12'

Chris answered some user comments and questions by listing some of the finish and fixtures they chose. Their goal: "modest and genuinely cost effective (and of course largely unspectacular)".

Another post compares photos of the actual modules in the factory and the renderings that Resolution 4 had provided to the homeowners in the design process.

Last Monday, Chris relayed a funny story about his Grandpa's take on modernist design.

I received an email from my friend/colleague Michael van Meter the other day. He and other volunteers are building homes in Armenia for charity using a unique pseudo-prefab building process:

One of the things that is desperately needed here is some type of affordable (and quickly constructed) quality housing. Enter my pal George who has many years of building expertise and has a heart for the poor of the world....George has been studying a product called Kiva Block for a couple of years now and has come up with a design that makes this product potentially viable. Kiva is made of Styrofoam of all things and goes together rather like Lego blocks. Think of a concrete block (CMU) that is 12 in high, 8 in thick and 48 in long....It is inexpensive, strong and quick. We have been working here 9 days now and are putting the roof on the first building and are going to start the roof on the 2nd tomorrow...pretty fast for a 2 bedroom 650 sf dwelling eh?

So anyway here we are setting a land speed record at building houses and perhaps there is a market for this thing in the world..."

Thanks Michael!

Update: By coincidence, ICF receives good coverage in the June issue of Residential Design & Build Magazine (hat tip: Materialicious).

A blog named DO Research showed up in a few places around the blogosphere. The blog is an "online note-to-self occasionally posted up on the internets for the unbuilt prefab home of Nicole Dotin and Eric Olson." They've been writing for a while; their coverage of the  Aperture House, mentioned here last week, got attention. Treehugger enjoyed the photos:

Aperture House, mentioned here last week, got attention. Treehugger enjoyed the photos:

"We love showing pictures of modern prefab, hoping that someday it will make good green design accessible and affordable. Nichole Dotin and Eric Olson plan to build a prefab and are clipping their own pictures of favourites. Where others might stick them in a file folder, they store them online as they move around the world from Minneapolis to Reading, UK."

I happened upon a blog that "tracks the building of our house, the first  NextHouse by

NextHouse by  Empyrean." The house is almost complete, and this week, the authors discussed the last-minute craziness of the project:

Empyrean." The house is almost complete, and this week, the authors discussed the last-minute craziness of the project:

"As move-in date draws nearer, all the things that need to be handled seem to be converging and conspiring to eat up all of our free time on weekends, and a bunch of time on weekdays as well."

Prefab Update discusses the efficiency of the 7.83 Hz House:

"It only requires two truck loads of materials to assemble, is built with sustainable materials, and is extremely energy efficient. The home is reconfigurable and low cost."

The  Sander Architects

Sander Architects  Hybrid House showed up on Treehugger. Lloyd Alter wondered about the prefab-ness of the home:

Hybrid House showed up on Treehugger. Lloyd Alter wondered about the prefab-ness of the home:

Most architects working in prefab are trying to create standard designs, to reduce the cost and risk to the client, and bring the services of talented architects to smaller houses. Sander thinks otherwise and says that 'What we love about the part prefab, all custom™ approach to prefab is that this will be YOUR house, designed exclusively for you...' He then follows an absolutely standard process of client engagement, design, design development and construction documents....

However I think it is a stretch to call it prefab."

Treehugger also showed off a new green home built with shipping containers:

"The R4House prototype consists of two bioclimatic homes (one of 150 m2 and a mini-flat of 30m2) made from materials that close the loop. The energy consumption of both is zero due to its bioclimatic design, the solar panels and the geothermal energy source. The waste production during construction is also zero. Both homes are modular and built from six recycled shipping containers; low-cost and allowing flexibility."

The University of Kansas School of Architecture and Urban Design runs a website/blog tracking their projects. They've been posting weekly on the construction of a new prefab in Kansas City. This week (week 19 of the project), they're nearing completion:

"Our goal was to be finished this week and have all of next week to tidy up and prepare for the open house on the 19th. With the exception of minute detail work, we have reached our goal. All of the siding is finished, the south deck is completed, and the ramp is being clad with Cumaru today. We can now finish our site work by bringing in sod in once high-trafficked areas to the south and between the house and garage."

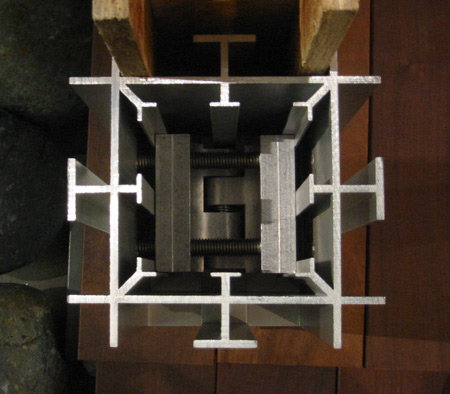

A while back, I wrote about the models from  kitHAUS. The product features an aluminum framing system called

kitHAUS. The product features an aluminum framing system called  MHS (Modular Housing System) developed by US Systems LLC:

MHS (Modular Housing System) developed by US Systems LLC:

"Our modules are constructed on site in a matter of days, not months, and because of [the framing system's] lightweight properties can get into the hardest [to] reach places, without heavy equipment."

I had the chance to see the system for myself at the CA Boom show, and thought it was quite impressive. Clamps are used to hold the structural members together; bolts are only used to tighten the clamps. The kitHAUS reps did inform me that power tools are necessary to tighten the bolts, as hand tools wouldn't achieve the proper torque.

The system manufacturer's website has images, and even a cool video (MHS.WMV at the bottom of the main page) to show how the system comes together. For those interested, there are detailed reports on the structural testing of the system.

A new blog called BLUEPRINT New Orleans explores the future of the city's design and culture. Here, Brad Brooks, talks about "prefab's promise" and the Dwell conference:

"While putting together an initial package of videos about new architectural trends in New Orleans, one of the more promising topics of interest was prefab..."

The San Francisco Chronicle ran a story on a prefab home in the area being built from parts from Austria:

"...what ultimately led Pierce and his wife, Peggy, to bring the Thoma Holz100 system to Walnut Creek was the environmental sensibility of using sustainable wood -- in this case, fast- and easy-growing European larch -- in a way that requires no glues, finishes or other chemicals. Various sizes of lumber are layered vertically, horizontally and diagonally to form the solid panels. Then dried wooden dowels are strategically pressed through drilled holes...and expand inside the panels to secure the structure."

Inhabitat's Prefab Friday covers David Adjaye's prefab home in the UK.

Cubeme has some thoughts and great pictures of  OMD's Seatrain, a house in LA:

OMD's Seatrain, a house in LA:

"In keeping with the artistic spirit of the community in which this house is being built, the project has been a collaborative experiment between the client, Richard Carlson, and the fabricators using a design/build approach where creative and structural decisions were made as the house was being constructed."

Treehugger talks about an aluminum framing system mentioned on Mocoloco mid-last year.

Future House Now covers Alchemy Architect's  weeHouse:

weeHouse:

"You know, there are some houses that just make you feel good when you see them. I always see fun in the "weeHouse" designs from Alchemy Architects. I can't believe I haven't done a post on them before. [Their] houses have such a cool vibe."

And so does a blog called Design Mind:

"These days the Weehouse is not so wee, but it started out as the little abode you see here. It was in production in the US early in the prefab boom and now has many design options for a full home. But it's this first model that I still love."

Here's a recap of prefab coverage from blogs and beyond.

Ecogeek shares thoughts on a new SIP-based prefab out of British Columbia:

"Why design with SIPs? First, as an Architect, I like to see my designs carried out as precisely as possible. Many SIP factories have computer aided manufacturing rigs that cut the panels to within a 1/16", which is unheard of in construction. Second, SIPs are energy efficient, they have minimal air leakage and very high R-Values."Also, check out our post on SIPs.

In March, Treehugger posted some good photos of the home coming together.

Last week, Inhabitat's Prefab Friday took a look at LA-based  Minarc's prefab offering:

Minarc's prefab offering:

"With their new M3 House they will be able to design and deliver an all inclusive package (minus the land and the foundation) that gives their clients a site specific house which also makes the most of the best qualities of factory built prefab...What's more incredible about M3 House is the limited amount of time spent on-site for final assembly. Once the foundation is complete, M3 House can have your 2,500sq foot home ready for furnishing in only 8-10 hours."This post also has an interesting series of comments about the "affordability" of prefab.

This week, Inhabitat highlighted a new container home from  LOT-EK:

LOT-EK:

"The idea is simple: transform a single shipping container into a single dwelling unit that is complete in its flexibility, mobility, and scalability. Designed for the modern-day nomad, the MDU can easily be transported from one spot to the next, fully-loaded with all the live/work amenities you could ask for."

Preston Koerner of Jetson Green comments on the "greenness" of large homes, and discusses with others in the comments:

"My values and beliefs were partially created through my experience living in Japan. I like minimalist. I like clean, sharp lines. I like modern. I like small, but functional. I appreciate that a grain of rice means something, especially when times are tough. And this is why I'm excited to hear the news of Muji coming to America..."

Rocio Romero was not present at CA Boom 4, but she and her team run a serious prefab operation. I spoke with Donna Rosanswank, Sales Manager, on the phone last week. 35

Rocio Romero was not present at CA Boom 4, but she and her team run a serious prefab operation. I spoke with Donna Rosanswank, Sales Manager, on the phone last week. 35  LV Series homes have been completed from the 100 LV Series kits sold since operations began in 2003. Many homes are built from more than one kit, and some projects have been delayed. Sales are doubling every year and they will expand into Canada by early next year.

LV Series homes have been completed from the 100 LV Series kits sold since operations began in 2003. Many homes are built from more than one kit, and some projects have been delayed. Sales are doubling every year and they will expand into Canada by early next year.

The LV series includes:

design:

• standard or customized floorplan (extra $ for custom design time)

• full set of construction documents (exceeds UBC and IRC requirements)

• list of materials, product specifications, and a construction schedule to help your local contractor realize your project

• a binder listing all of the suppliers used to build the original show home; this will help homeowners source materials that are not included in the kit

materials shipped with the kit:

• exterior wall panels

• structural components for floor and roof

• exterior siding

materials that are NOT included:

• interior framing materials

• interior finishes

• windows and doors

• fixtures (plumbing and lighting)

• roofing

The home kits include so few finish materials because "Rocio wanted to be able to fit the whole kit in one flatbed delivery," and to allow customers flexibility in the final product.

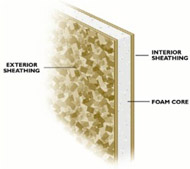

Many of the prefab models coming onto the market, like the  CleverHomes, are built with a technology called SIPs. The acronym SIP stands for Structural Insulated Panel; the lowercase "s" is usually added to pluralize.

CleverHomes, are built with a technology called SIPs. The acronym SIP stands for Structural Insulated Panel; the lowercase "s" is usually added to pluralize.

A SIP contains a 4" - 6" foam layer sandwiched between two layers of rigid material, usually oriented strand board (like plywood, but each layer is made of many small wood chips), plywood, or fiber cement board. This sandwich is the total thickness of your wall, roof or floor, minus the finishes.

The benefits of SIP include the ability to ship a wall panel to your house site that is cut to size and ready to install. Insulation and framing are handled in one step. Compared to standard stud-framing, the SIP is more likely to be the right dimensions, be flatter (compared to the waviness of the studs) and to have a built-in insulation system. The crew on site just fits the panels together.

The general critique of SIP construction in the home-building world is the initial cost, due to most of the labor being offsite in the factory. Considering we are discussing prefab, however, most of the labor for any product will be in the factory. Environmentally conscious folks might take issue with the use of such large quantities of foam in the panels. However, SIPs save construction waste on site, and ensure that your home will have one of the best energy efficiencies possible for the given wall thickness.

If you decide to build a home with SIPs, prefab or not, you need to make sure your contractor has prior experience with this method, as SIP construction is different from traditional construction. And, if the designer doesn't provide oversight, the contractor must make sure that drawings are accurate prior to approving for manufacture. Additionally, installation of electrical, plumbing and mechanical systems will require special techniques.