Many of the prefab models coming onto the market, like the  CleverHomes, are built with a technology called SIPs. The acronym SIP stands for Structural Insulated Panel; the lowercase "s" is usually added to pluralize.

CleverHomes, are built with a technology called SIPs. The acronym SIP stands for Structural Insulated Panel; the lowercase "s" is usually added to pluralize.

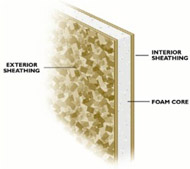

A SIP contains a 4" - 6" foam layer sandwiched between two layers of rigid material, usually oriented strand board (like plywood, but each layer is made of many small wood chips), plywood, or fiber cement board. This sandwich is the total thickness of your wall, roof or floor, minus the finishes.

The benefits of SIP include the ability to ship a wall panel to your house site that is cut to size and ready to install. Insulation and framing are handled in one step. Compared to standard stud-framing, the SIP is more likely to be the right dimensions, be flatter (compared to the waviness of the studs) and to have a built-in insulation system. The crew on site just fits the panels together.

The general critique of SIP construction in the home-building world is the initial cost, due to most of the labor being offsite in the factory. Considering we are discussing prefab, however, most of the labor for any product will be in the factory. Environmentally conscious folks might take issue with the use of such large quantities of foam in the panels. However, SIPs save construction waste on site, and ensure that your home will have one of the best energy efficiencies possible for the given wall thickness.

If you decide to build a home with SIPs, prefab or not, you need to make sure your contractor has prior experience with this method, as SIP construction is different from traditional construction. And, if the designer doesn't provide oversight, the contractor must make sure that drawings are accurate prior to approving for manufacture. Additionally, installation of electrical, plumbing and mechanical systems will require special techniques.