Postgreen Homes recently announced their newest project in Philadelphia, built with SIPs.

Postgreen Homes recently announced their newest project in Philadelphia, built with SIPs.

We are building three new homes on E. Susquehanna Ave in East Kensington, just a few doors down from the original 100k Project.

They are calling these homes "The Skinny Project".

...named for the new model we will be debuting in this build. The Skinny, designed to fit on Philadelphia’s narrow lots, offers an extremely flexible, open floor plan.

They also launched a home customization tool for the Skinny and three additional models:

| Model | BR | Bath | Price |

|---|---|---|---|

Family Family |

2 | 1-2 | starting at $260,000 |

Loft Loft |

1 | 1 | starting at $250,000 |

Work Work |

1 | 1 | starting at $250,000 |

This house made with SIPs was created as a model for "sustainable, affordable housing" in Atlanta, GA.

From their model page (emphasis added):

Above the concrete base, the house is constructed of Structural Insulated Panels (SIP). These panels are pre-cut and pre-wired to match builder specifications and include the interior GWB finish wall, allowing the house to be constructed by three people in two days, generating significant savings in construction time and cost.

The SIPs are attached to one another and do not require additional stick framing. The structure acts as a shell, is typically 30% stronger than a comparable wood stud home, and allows greater design flexibility.

The budget for the project: $160,000.

Hat tip: "+ MOOD" on August 7, 2009.

Nelse Design + Build constructed their first house using SIPs for the walls and roof:

Nelse Design + Build constructed their first house using SIPs for the walls and roof:

From their Green Cubed website:

The core idea of this project is relatively basic; develop a home design and building system for urban infill lots (in this case, Seattle) that is modular enough to maximize design and construction efficiencies, adaptable enough to respond to each unique site and occupant, and sustainable enough to provide a healthy, environmentally friendly, and energy efficient home for generations of urban dwellers.

A slide show is also available on the site.

Hat tip: Jetson Green on June 18, 2009.

materialicious recently linked to an interesting Dwell Magazine article from 2005. The article covered a mountaintop house built with prefab elements by  Anderson Anderson Architecture.

Anderson Anderson Architecture.

the house adds an interesting case study to the ongoing research project that is prefabricated building—another rung to the ladder the building industry needs to climb to maximize prefab’s potential

From the slideshow:

Architect Peter Anderson explains that “the floating nature of the design would not have been possible with conventional onsite framing techniques, nor any of the currently marketed modular home designs.” Using a heavy structural steel frame, engineered wood spline beam system, and structural insulated panels, the architects created a truly unique hybrid structural system and, in the end, a home.

The use of structural insulated panels (SIPs) throughout the house helped speed the construction process. Peter Anderson explains, "The panels themselves hang from and rest upon the steel frame and wood spline beam system, which is the link between the steel frame and the panels. The SIPs provide enclosure, insulation, and the spanning capacity to support the cast-concrete floor."

Read the article for more information.

GreenSource Magazine recently named their Best Green House for April 2009.

Its exterior is constructed of SIPs, while wood-stud partitions make up the interior partitions.

Read the entire article for more information and to see additional pictures.

Hat tip: Jetson Green on April 30, 2009.

The home page of Dwell Magazine currently features a 2005 article about a house in Wisconsin built using SIPs. It was designed by David Salmela of  Salmela Architect.

Salmela Architect.

The larger of the two units (which contains the kitchen, dining area, lounge, master bedroom, bath, and screen porch) is 900 square feet, and the smaller (where the guest room and bath, office area, and mechanical room are located) measures 360 square feet. The house, which was finished in 2003, cost $295,000 to build.

Read the entire article for more information.

Apartment Therapy Re-Nest recently covered a house in East Hampton, NY built with SIPs.

The architect's site has more pictures and info:

Old Stone Highway house [was] conceived as a modern interpretation of the Long Island agricultural vernacular while also incorporating the use of environmentally low impact building technology.

Inhabitat recently shared an interesting remodel by  Blackburn Architects:

Blackburn Architects:

Original barn walls were used as the interior paneling, with a layer [of] SIPs for insulation and stability, plus an exterior layer of new board-and-batten for the cladding.

Check out the post for more pictures.

Hat tip: materialicious on April 17, 2009.

Arch Daily recently highlighted an interesting Hybrid House by  konyk.

konyk.

Modeled after the successful Prius Hybrid automobile by the Toyota Motor Company, HYBRID HOUSE is intended to be an electric house completely off the local utility grid.

The central volume is constructed of 12-1/4″ thick structural insulated panels... Not only are the SIP panels self-supporting, the lightweight pre-cut panels require little energy to transport, and are easily assembled with manual tools and labor at the job site. Fenestration and doorways are achieved by cutting holes through the structural insulated panels, and then capping with standard flashed operable skylight and storefront systems.

See the post for details, including several more pictures.

The comments are also interesting, e.g.

Part of being a good architect is not only creating innovative buildings but to also not disrupt the line of vision in a neighbourhood.

The Alternative Consumer recently featured ModestHouse by  Jeffrey McKean Architects.

Jeffrey McKean Architects.

ModestHouse utilizes a system of pre-manufactured components such as structural insulated panels (SIPS) for the roof, walls and floor; and FSC certified timber for primary framing. Pre-fabricated building components are assembled on site to save time and materials.

See the post for a few more pictures.

We found model information on their site:

Watch their animated assembly video (1:17).

The Structural Insulated Panel Association has a conference in April:

The SIPA Annual Meeting & Conference is the only industry-wide event for SIP professionals. Structural insulated panel manufacturers, builders, design professionals and suppliers of SIP components will convene in Chicago at this unique trade show and conference.

...

attendees can explore the latest marketing and technical developments in the SIP industry.

(We've covered several prefab and modular homes that use SIPs.)

Hat tip: Building Systems on March 24, 2009.

materialicious recently covered a home in Michigan called  Cottage in a day

by architect

Cottage in a day

by architect  Michael Fitzhugh:

Michael Fitzhugh:

Cottage in a Day is a modern, modular pre-fabricated structure based on a 14 foot square module. The cottages are built using structural insulated panels for floor, walls and roof....

Once transported the cottage modules were then assembled in five hours.

The company offers 4 models:

| Model | Price | Size | BR | Baths |

|---|---|---|---|---|

1414-S 1414-S |

$52,000-$56,000 | 182-282 sf | 0-1 | 1 |

1428-S 1428-S |

$115,000 | 375-570 sf | 0-1 | 1 |

1428-SB 1428-SB |

$117,000 | 375-570 sf | 0-1 | 1 |

142814-L 142814-L |

$152,400-$156,500 | 375-570 sf | 1-1.5 | 1 |

Check out the assembly videos on their website.

Treehugger's Lloyd Alter recently attended the Greenbuild International Conference and Expo in Boston. He describes Agriboard Structural Insulated Panels (SIPs) made by Agriboard Industries as

perhaps the best thing I saw

We previously covered SIPs and how they are made.

In constrast, an Agriboard SIP:

... uses wheat and rice straw that is normally burned or ploughed under, and builds it into a panel that delivers R-25, not as good as a styrofoam SIP but pretty good and in a form that gives you a tight envelope.

Recently, Boston Magazine featured an article about the VH R-10 gHouse on Martha's Vineyard.

Why SIPs?

Because he couldn't be on-site every day, [Petrucci] decided to use a premanufactured structural insulated panel system built in a factory in New Hampshire and shipped to the site to be erected..."Prefab panels are a single stroke solution for structure and insulation, and they go up fast," says Petrucci. In fact, it took just three days to get the entire structure up.

Also worth noting: Petrucci is the director of the School of Architecture and Landscape Architecture at Arizona State University.

Read the entire article for more details.

(Hat tip: materialicious on October 20, 2008)

Architectural Record shared an online excerpt of an April 2008 article about the VH R-10 gHouse on Martha's Vineyard.

Where did they come up with the name?

- VH = Vineyard Haven, the town on Martha's Vineyard where the house is located

- R-10 = the zoning district

- gHouse = guest house

[The house was] so profoundly shaped by local restrictions that it adopted the zoning district—R-10—as part of its name.

The local restrictions seem tight:

Guesthouses in the district...may encompass no more than 600 square feet, their height may not exceed 24 feet...the basement may not be accessed from the building’s interior.

But the architect managed to work around them:

The small loft and spacious lower-level guest suite do not count toward the square footage allotted by zoning so, cleverly, 600 technical square feet become 1,000 square feet of livable space.

Details on the house:

Be sure to check out the images:

Core 77 reports:

Before pre-fab became so fabulously fab, the Small Homes Council at the University of Illinois in Urbana, Illinois published Homes From Pre-Assembled Wall Panels in 1954.

A bit more about the Small Homes Council, now known as the Building Research Council:

For over 50 years, BRC (formerly known as the Small Homes Council) has conducted housing research and provided public service to residents, homeowners, builders, contractors, engineers, architects, and others in the housing industry. Today BRC continues to draw on the expertise of its own staff and a campus-wide network of experts to improve the state of our built environment.Current research projects include studies on building performance, moisture control, toxicity issues in residential building materials, windstorm resistance, diversity issues in the architectural profession, and housing environments design and evaluation.

We could not locate the book on AbeBooks.

Still employing similar techniques:

•  LV Series

LV Series

•  Modern Shed

Modern Shed

Here's a unique hybrid wall panel, sort of half SIP, half straw bale:

The Enviro Board panels offer a superior building product that is easy to handle and assemble. Today's Enviro Board Panels are solid "concrete like" fiber panels comprised of highly compressed straw fibers. Through the Enviro Board technology, panels are extruded through the mill in a continual process, covered with a durable waterproof paper membrane, cut to desired lengths and end-capped. Panel density and thickness can also be adjusted.The Enviro Board panel replaces conventional and traditional building materials, such as drywall, thermal insulation, exterior moisture barrier (typically tar paper) and exterior plywood. In addition, because of its 32" width, using Enviro Board panels requires 50% less studs and eliminates unnecessary expenses in the form of materials and labor needed to assemble the materials.

From YouTube:

(Hat tip: Materialicio.us)

At the building conference last month, I spoke with a rep at ParcoHomes, a prefab start-up out of San Francisco. From what I gathered, the company plans to employ mass production techniques currently used for commercial buildings. Parts would be manufactured offshore, packaged, and shipped by sea and truck to your homesite. From the ParcoHomes website:

"We are designing, manufacturing and distributing resource efficient, modern, prefabricated homes employing a 'flat-pack' delivery approach. Our kit of parts is made up of metal-framed floor, roof and wall panels supported on a structural frame. The entire kit of parts is based on a four-foot planning module to allow for an ideal balance between constructability and flexibility."

EcoInfill is currently building the prototype of their Ei1 concept. The concept home's flexibility allows it to "be installed as a single family home, addition, or entire townhome project." I spoke with someone from Sexton + Lawton Architecture, the designers of the homes. He said that the homes will cost them ~$95/sf coming out of the factory; this translates to ~$175/sf installed. While the model home is not yet complete, they are hoping for a 3 month timeline from foundation work to move-in.

SG Blocks repurposes shipping containers for architectural purposes. Many companies building from recycled shipping containers are sourcing their product from SG Blocks. I spoke with a rep who explained that the $200/sf+ cost of building with recycled shipping containers is justified by the added strength and durability.

In addition to these prefab builders, there were a number of SIP manufacturers present. These include Alternative Building Concepts, Shimotsu Architecture and Distribution, and SIP Home Systems. I saw some interesting features, like pre-drilled mechanical chases for electrical connections.

Steve Kieran's  Loblolly House takes flat-pak prefab to a whole new level. Kieran's firm

Loblolly House takes flat-pak prefab to a whole new level. Kieran's firm  KieranTimberlake created a series of panels and structure that integrate all of the home's mechanical systems:

KieranTimberlake created a series of panels and structure that integrate all of the home's mechanical systems:

The assembly process begins with off-site fabricated floor and ceiling panels, termed 'smart cartridges.' They distribute radiant heating, hot and cold water, waste water, ventilation, and electricity through the house. Fully integrated bathroom and mechanical room modules are lifted into position. Exterior wall panels containing structure, insulation, windows, interior finishes and the exterior wood rain screen complete the cladding."

Hive Modular,

Hive Modular,  Marmol Radziner, and

Marmol Radziner, and  Alchemy Architects, integrate utilities into multi-room modules that are shipped to the site near-complete. But the companies delivering flat-packed products, like the

Alchemy Architects, integrate utilities into multi-room modules that are shipped to the site near-complete. But the companies delivering flat-packed products, like the  LV Series homes from

LV Series homes from  Rocio Romero, require on-site work to incorporate utilities and finishes. The SIPs or stud-framed panels they ship generally incorporate little more than structure and insulation.

Rocio Romero, require on-site work to incorporate utilities and finishes. The SIPs or stud-framed panels they ship generally incorporate little more than structure and insulation.

For the Loblolly House, this complete prefabrication was necessary to avoid large amounts of work on the sensitive site. The process even works in reverse:

"Just as the components may be assembled at the site swiftly with a wrench, so may they be disassembled swiftly, and most importantly, whole....It is a vision in which our architecture, even as it is disassembled at some unknown moment, can be relocated and reassembled in new ways from reclaimed parts."

Complementing the designs of Ray Kappe and David Hertz,  LivingHomes plans to sell homes based on the system used in the Loblolly House. Also worth noting: Bosch produces the structural frame used for the Loblolly House and the TK iT House.

LivingHomes plans to sell homes based on the system used in the Loblolly House. Also worth noting: Bosch produces the structural frame used for the Loblolly House and the TK iT House.

(Hat tip: Philly.com)

Earlier coverage: Wired article on Plug and Play Construction (January); Architectural Record (April).

I recently had the opportunity to ask a few questions about the new product line from  Jenesys Building Systems. Here's what I learned:

Jenesys Building Systems. Here's what I learned:

Have you constructed any prefab structures?

Yes. Two. Our first was a small one-off cabin, the precursor to our current line of prefab buildings that we are developing. The second is the prototype of our E Cube line.

Are any models available for sale with timely delivery?

All the models on our website are currently available for sale. Time of delivery depends on the specific options and degree of customization that a customer opts for, but we do have a chain of supply in place and are ready to take orders.

You mention the prototype; do you have any photos, imagery or other documentation of the process/final prototype?

We have some information on this page: http://jenesysbuildings.ca/products-ecube.html

Our prototype E Cube is now at "lock up", structurally complete with doors and windows. [We anticipate] completion of the finishing of the building and landscaping this summer.

Standard features of the  E Cube include:

E Cube include:

• 8 inch thick SIP walls (R 40)

• 6 inch thick SIP roof with 10-12 inches batt insulation (R 60)

• exterior sun screens

• energy-efficient dual-glazed windows

Optional features include:

• solar panels

• triple-glazed windows

Additional coverage at Ecogeek, Treehugger , and Moco Loco.

The BRE Group is a British "research, consultancy, training, testing and certification organisation delivering sustainability and innovation across the built environment and beyond." They reported this week on the Osbourne demonstration house, built from SIPs:

The house needs two thirds less energy for heating and cooling than a house constructed to 2006 Building Regulations."

• a zinc and slate clad cassette roof that requires no trusses or rafters

• off-site manufactured bathroom pod and door sets

• a plug-together wiring system

• timber I-beam floor joists.

Architecture.mnp posted some unique views of the Maison Tropicale in the rain, plus a nice interior shot.

kitHAUS takes a different approach to prefab than the other vendors at CA Boom 4. The

kitHAUS takes a different approach to prefab than the other vendors at CA Boom 4. The  kitHAUS models feature a patented lightweight aluminum framing system with SIPs between the structural members.

kitHAUS models feature a patented lightweight aluminum framing system with SIPs between the structural members.

The custom clamping technique of the MHS (modular housing system) reduces site construction time to a few days. The lightweight aluminum can be assembled without heavy equipment, is resistant to rust and termites, and never needs to be painted.

Exterior cladding is offered in Zinculume (corrugated metal panels) or Ipe wood, both of which are weather resistant and durable. Interior surfaces come un-finished, requiring you and your local contractor to handle flooring and wall coverings, and all cabinetry, lighting, and other fixtures.

kitHAUS offers four standard modules, as well as 5 example configurations on their website. The standard building blocks are 17' square.  K1 features a loft;

K1 features a loft;  K2 has a flat roof. The

K2 has a flat roof. The  K3 module is smaller, at 9' x 13', and the

K3 module is smaller, at 9' x 13', and the  K9 module (an actual offering) is a 4' x 4' home for your dog. The configuration examples range from 512 sf to 768 sf, but it is possible to combine more modules to create a dwelling (or doghouse) of any size.

K9 module (an actual offering) is a 4' x 4' home for your dog. The configuration examples range from 512 sf to 768 sf, but it is possible to combine more modules to create a dwelling (or doghouse) of any size.

The kitHAUS system offers a flexibility that is unmatched by any other home at the CA Boom show. The lightweight framing system and ease of assembly allow the kitHAUS to go places other prefab can't. For instance, if your homesite is on an island, or up some windy mountains roads, the kitHAUS can make the journey.

Energy-efficiency and the environment are topics that are mentioned often by the prefab companies at CA Boom. The features of the  H-Haus models don't take these topics lightly. H-Haus describes its services as "home design for a smart energy future."

H-Haus models don't take these topics lightly. H-Haus describes its services as "home design for a smart energy future."

The H-Haus line consists of 8 standard models, varying in size from a 612sf standalone guest house module, to a 2,100sf home, with garage, terrace, and two bedroom "suites." The models range in overall appearance, from the modern  Cube 5 to the traditional/modern hybrid of the

Cube 5 to the traditional/modern hybrid of the  Cube 8. LIsted prices are in the $200k - $300k range. Most of the models feature colorful stucco finishes; other exterior finish options include metal siding, Hardiplank®, and Cultured Stone®. Several amenities are worth a mention: a standard 10'-0" height entry door, operable skylights, soaking bathtubs, gas fireplaces, and trellises for outdoors terrace areas, to name a few.

Cube 8. LIsted prices are in the $200k - $300k range. Most of the models feature colorful stucco finishes; other exterior finish options include metal siding, Hardiplank®, and Cultured Stone®. Several amenities are worth a mention: a standard 10'-0" height entry door, operable skylights, soaking bathtubs, gas fireplaces, and trellises for outdoors terrace areas, to name a few.

All models strive to combine a well-designed product with eco-friendly features. For example, the standard for Cube walls is an 8" pre-engineered system (compared to a 4" - 6" standard thickness in most homes), allowing for a great r-value (in the range of R-30 to R-50). Other features: energy-efficient windows, solar heating, rainwater catchment and wastewater recycling.

While such inclusions aren't revolutionary, or unique to H-Haus, the H-Haus folks do make a notable effort to incorporate green materials and products into their homes. To stress these features, while also trying to meet a certain aesthetic, IS a challenge. If you are seeking a low-impact prefab product, you should certainly look in the direction of H-Haus.

Many of the prefab models coming onto the market, like the  CleverHomes, are built with a technology called SIPs. The acronym SIP stands for Structural Insulated Panel; the lowercase "s" is usually added to pluralize.

CleverHomes, are built with a technology called SIPs. The acronym SIP stands for Structural Insulated Panel; the lowercase "s" is usually added to pluralize.

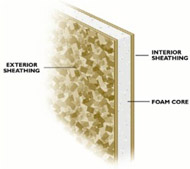

A SIP contains a 4" - 6" foam layer sandwiched between two layers of rigid material, usually oriented strand board (like plywood, but each layer is made of many small wood chips), plywood, or fiber cement board. This sandwich is the total thickness of your wall, roof or floor, minus the finishes.

The benefits of SIP include the ability to ship a wall panel to your house site that is cut to size and ready to install. Insulation and framing are handled in one step. Compared to standard stud-framing, the SIP is more likely to be the right dimensions, be flatter (compared to the waviness of the studs) and to have a built-in insulation system. The crew on site just fits the panels together.

The general critique of SIP construction in the home-building world is the initial cost, due to most of the labor being offsite in the factory. Considering we are discussing prefab, however, most of the labor for any product will be in the factory. Environmentally conscious folks might take issue with the use of such large quantities of foam in the panels. However, SIPs save construction waste on site, and ensure that your home will have one of the best energy efficiencies possible for the given wall thickness.

If you decide to build a home with SIPs, prefab or not, you need to make sure your contractor has prior experience with this method, as SIP construction is different from traditional construction. And, if the designer doesn't provide oversight, the contractor must make sure that drawings are accurate prior to approving for manufacture. Additionally, installation of electrical, plumbing and mechanical systems will require special techniques.

The next player at the CA Boom 4 show will be  CleverHomes. Their design and process is in contrast to the simplicty afforded by the weeHouse. As a result, more is possible with a CleverHome.

CleverHomes. Their design and process is in contrast to the simplicty afforded by the weeHouse. As a result, more is possible with a CleverHome.

CleverHomes details 8 unique models on their website, along with 7 custom case-studies to show how their system can be tweaked and customized. The sizes run the gamut, from a 480sf one-room wood-sided shack, to a large 3,500+ sf modern estate. Styles range from ultra modern to log-cabin chic. All are rectilinear, and most feature flat roofs.

The design process includes a custom design for your lot and setting, satisfying the unique structural and site constraints of any project.

In contrast to the factory-built, fully finished, units that you get with a product like the weeHouse, CleverHomes are shipped to the site in unfinished pieces. Exterior wall sections, called SIPs, industry shorthand for "structural insulated panels", are shipped to the site and are erected by your choice of contractor, with oversight from the CleverHomes folks.

Finishes and fixtures are shipped separately, but "are delivered ready for on-site assembly". Construction schedules are stated to run in the "4-6 month" range. CleverHomes touts this somewhat-prefab process, saying that they "stop short of pre-fabricating large assemblies" when the factory process becomes limiting architecturally, or if the cost of moving a large prefab module would be too high.

CleverHomes is taking advantage of the prefab process in a way that most likely will become more common in the coming years. They are taking advantage of the quality control and cost-savings of the factory and a few pre-engineered schemes, while still allowing for a near-custom home as a product.