The San Francisco Chronicle reports that Michelle Kaufmann has sold the building rights to several of her  MK Designs homes to

MK Designs homes to  Blu Homes.

Blu Homes.

Designs include:

According to the article:

They have developed a proprietary unfolding modular technology that will enable cost savings to be made on Kaufmann designs at the shipping and on-site building stages. Elements that make up the homes such as wall panels are created with hinges so they can be compacted for transportation and unfolded on site. The MK Designs homes will have slightly different floor plans, proportions and elevations from the originals, although, Kaufmann said, the design principles should remain the same.

Blu Homes plans to market the homes nationwide.

The Baltimore Sun recently featured a Habitat for Humanity project consisting of nine factory-built homes in Chesapeake, MD.

According to the article:

Factory-built houses aren't just quick to put up, they're cheaper than homes constructed on-site. Advocates for lower-income residents are realizing that, done right, there's nothing of the much-maligned trailer park about houses coming off today's assembly lines.

Interesting to note:

Habitat's modular-home buyers are getting the whole package, land and all, with no-interest loans from the organization. Including pricey site work but not the cost to buy the land, each house cost Habitat $120,000. When the group built homes from scratch last year in Southwest Baltimore, the construction and site work totaled nearly $160,000 per house.

They include a video (1:54) discussing the project.

The October 2009 issue of Dwell Magazine features a shipping container home in Houston, TX.

the corrugated steel of three containers—two 40-foot-long modules and one 20-foot-long unit—form the northern, southern, and western facades, with a glass wall to the east completing the perimeter

Another 40-foot container serves as a guest house and storage unit.

Here's some pricing info from Numen Development's site:

Our completed projects have ranged from $100/sq.ft. to $150/sq.ft

Dwell includes a slideshow of 23 pictures.

The September 2009 issue of Midwest Home Magazine featured a modular home in St. Paul, MN.

According to the article:

A 240-ton crane showed up at 8:30 a.m., and a crew of 20 started work. The wood-framed, fiberglass insulated, Hardieplank modules—already dry-walled, wired for electric, and plumbed—were screwed together, patched, mudded, and…voila! By 1:30 p.m., the house was ready for finish work

Hat tip: Jetson Green on September 4, 2009.

The Arizona Republic recently discussed the evolution of prefab homes.

Modular houses, usually built in 14-foot-wide sections and assembled at a home site, have evolved from mobile homes of questionable durability into better-built houses with many of the same finishes and features of standard production houses.

Companies mentioned in the article:

Also mentioned, two Arizona communities:

- Dolce Vita at Superstition Mountain in Apache Junction

- Tuscany Villas at Painted Mountain in Mesa

The Denver Post recently covered the Aria Denver project.

In addition to the new homes for the nuns, the company is developing about 17 acres it's buying from the sisters. The first phase of the project, which ultimately will include 270 residences, is expected to start construction by the end of the year.

...

They'll be priced from $250,000 to $500,000 and range in size from 960 square feet to 1,600 square feet.

An article in the July/August 2009 issue of The Atlantic mentions efficiency improvements in housing as a way to ease our reliance on carbon.

The problem:

slightly more than half of the energy consumed in the United States goes to buildings: 12 percent for constructing them, and 39 percent for heating, cooling, and lighting them

According to Marc Porat, "a serial entrepreneur in the 'built environment' sector" and Chairman of  ZETA Communities:

ZETA Communities:

“The easiest, fastest, most effective way to reduce energy demand is to hit buildings”

Porat’s Serious Materials makes high-efficiency windows and low-energy drywall; CalStar Cement uses fly ash to make low-carbon bricks and cement; Zeta Communities puts up town houses with minimal carbon footprints.

(From ZETA's site: "ZETA's core business is factory-built production of residential and non-residential structures.")

In July, The Neosho Daily News in Missouri featured a modular house put together by students in building trades classes at Crowder College.

[The] house was built modular style so it can be moved easily.

The only details we could find:

Interesting to note:

They held an open house and accepted "bids for the house with the winning bid subject to approval by the board of trustees."

The February 2009 issue of Dwell Magazine featured a modular home in Lost River, Virginia.

Worth a look: slideshow of 7 pictures.

Note: The house was built in 2007 - 2008. The owners tracked the entire process via their blog: A PreFab Project. Check out our related posts for more information.

Hat tip: Apartment Therapy on August 7, 2009.

The  casa ti prototype by

casa ti prototype by  Green Modern Kits has been covered in the news recently, according to a post by Copeland Casati:

Green Modern Kits has been covered in the news recently, according to a post by Copeland Casati:

NBC12 in Richmond, Virginia on August 4, 2009 includes a video (2:03)

C-ville Abode in Charlottesville mentions the house in their Green Scene section dated August 4-10, 2009

A month ago, The Saratogian featured this 3-unit modular home in Saratoga Springs, NY.

According to owner, Helena Frost:

This is totally custom made in the factory...It really helped cut down on the cost, about $40 less per square foot.

See our earlier post for more details.

The Los Angeles Times recently covered a prefab house being built by students from Santa Clara University and California College of the Arts.

According to a video (5:48) on their site, the house is constructed from 3 modules arranged in a u-shape.

Refract House will be on display this October at the National Mall in Washington, DC as part of the U.S. Department of Energy's Solar Decathlon.

The Solar Decathlon joins 20 college and university teams in a competition to design, build, and operate the most attractive and energy-efficient solar-powered house.

For more info on the project, see:

- documentary (6:54)

- blog

The New York Times recently featured a ranch retreat that we covered in April.

Cinco Camp is unlike most other shipping-container structures in that the boxes have been left intact, rather than being cut, contorted and connected. The containers and the bar-grate steel decking that runs between them have the same rusty patina as West Texas cattle guards and barbed-wire fences. Hovering above the house and shielding it from the sun are the five slanted, shed-like covers held aloft by I-beams.

Worth a look: slideshow containing 11 pictures.

Interesting note: The owner, Roger Black, "was the art director at Rolling Stone in the 1970s, and at The New York Times and Newsweek in the 1980s, is now a publications consultant and a partner of Font Bureau Inc."

Hat tip: Apartment Therapy New York on July 16, 2009.

The Valdosta Daily Times in Georgia recently covered an open house at  Affinity Building Systems, LLC.

Affinity Building Systems, LLC.

The company manufactures modular homes that are green, affordable and of a high-quality, and have over 24 designs to choose from.

On display:

According to the article:

once the different components of the house were built in the factory, it took about two-and-a-half hours to put them together on the desired spot. Then, for about two weeks the builders finished the walls, laid down the carpets, mounted the garage doors, finished the roofs, and did some final cosmetic work

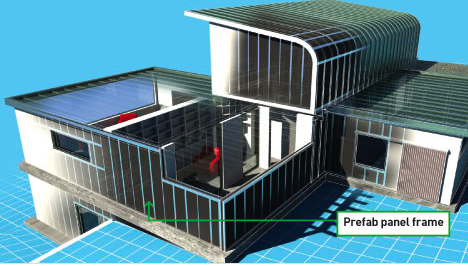

Popular Science recently featured a project using a new type of prefab panel frame by  kama Energy Efficient Building Systems.

kama Energy Efficient Building Systems.

These aren't your conventional structural insulating panels. Instead of foam and strand board, Kama...custom-makes the rigid panels out of light-gauge metal studs and a special type of expanded polystyrene called Neopor that's non-toxic, fully recyclable and blended with graphite to lock out heat, moisture and mold.

According to John B. Carnett, the Popular Science staff photographer who is building the house:

They cost me about 5 percent less than a stick frame would have, but they're 60 percent more energy-efficient and can cut heating and cooling bills in half.

The price listed in his specs for the prefab panel box installation is $7.04 per sf.

Carnett claims to be "the first in the U.S to incorporate Kama's new panels."

House details:

Follow progress via his blog.

Hat tip: Jetson Green on July 21, 2009.

Sunset Magazine recently featured the construction of an  LVM kit home by

LVM kit home by  Rocio Romero in Tucson, Arizona.

Rocio Romero in Tucson, Arizona.

For $22,050, the LVM kit included plans and the exterior shell and walls of the house, along with siding and a list of suggested finishes from Lowe’s and Ikea.

The article includes a slideshow of the 12 week building process.

Hat tip: re-nest on July 16, 2009.

Last month, the San Francisco Chronicle featured factory-built homes by  ZETA Communities. ZETA stands for "Zero Energy Technology and Architecture".

ZETA Communities. ZETA stands for "Zero Energy Technology and Architecture".

Zeta hopes to capture the market for multifamily townhomes, lofts and apartments that are affordably priced and complement environmentally conscious smart growth

...

a two-bedroom live-work townhome would be sold to developers for approximately $258,000 per unit, including shipping, installation and mechanical systems and appliances

The Chronicle's blog previously covered ZETA's demonstration home in Oakland.

Interesting to note:

[ZETA] is not intending to do business directly with homeowners. Rather its business model is based on marketing itself to architects and developers by taking existing building plans and figuring out how to build them in modular pieces.

We missed this article last fall. Natural Home Magazine featured a prefab home designed and built by students in the Studio 804 program at the University of Kansas School of Architecture and Urban Planning.

built in six modular units in nearby Lawrence, Kansas, where the Studio 804 program is based, then trucked 40 miles to Kansas City and assembled

The students designed and built the home over the course of five months.

Check out the photo gallery and video (3:07).

Hat tip: Low Impact Living Blog on June 22, 2009.

Not mentioned in the article or post: the house was built back in 2006.

The upcoming issue of Dwell Magazine will feature a hybrid home by  Christopher Campbell Architecture.

Christopher Campbell Architecture.

The wedgelike shape of the house, the red prefabricated steel frame glimpsed between the slats of two-by-eight-foot pine siding, and the roll-up firehouse doors on the seaward facade all owe a debt to the working buildings of Maine.

...

The metal frame and wood panels that line the interior were constructed in a barn on the mainland then shipped out by barge. Work crews took lobster boats out to the island each day; the spiral staircase from the main room to the master bedroom was fabricated in a Maine shop; and the granite in the foundation is from Mosquito Mountain near Bucksport. The doors are from Bristol and the builder, Scott Pearson, whom Campbell frequently praises to the skies, is a homegrown Mainer.

View their slideshow.

Los Angeles Times recently featured mini prefab structures, including a photo gallery.

Companies mentioned:

Hat tip: materialicious on June 15, 2009.

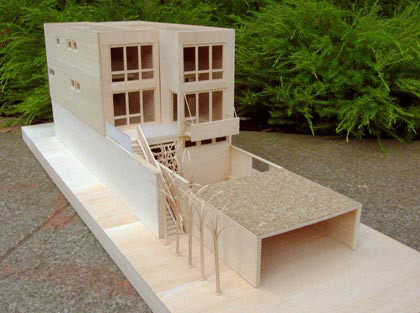

On Monday The New York Times featured a residential project in Germany by architect Daniel Libeskind.

The house is designed as three interlocking structures and most of the elements will be manufactured in a factory.

Interesting to note: Daniel Libeskind designed "the Jewish Museum Berlin and the master plan for the reconstruction of the World Trade Center site in New York".

“I did everything in reverse in my career,” he said. “Most people start with small projects and go on to design a museum. I started with a museum.”

But he says residential design is “the more interesting part of architecture.”

“Too often we celebrate great civic institutions,” Mr. Libeskind continued, “but actually architecture is how people live and how well they live.”

Read the entire article for more.

Hat tip: Jetson Green on June 15, 2009.

Alchemy Architects recently mentioned that

Alchemy Architects recently mentioned that  weeHouse is covered in the inflight magazine for Continental Airlines this month.

weeHouse is covered in the inflight magazine for Continental Airlines this month.

We looked around and found the link:

Builder Magazine recently highlighted 6 prefab houses that could change the future of home building:

-

ma Modular by

ma Modular by  KRDB

KRDB

-

Unity Collection by

Bensonwood

Bensonwood

-

Simple Cottage Sampler by

Russell Versaci Architecture and

Russell Versaci Architecture and  Haven Homes

Haven Homes

-

BrightBuilt Barn by

BrightBuilt Barn by  Kaplan Thompson Architects and

Kaplan Thompson Architects and  Bensonwood

Bensonwood

-

IKEA.SmartCarHouse by

BSB Design

BSB Design

-

HOM Escape in Style by

HOM Escape in Style by  KAA Design Group

KAA Design Group

[Y]ou’d think that with [traditional home] prices falling as fast as a brick that prefab housing would be a non-factor, but just the opposite appears to be true. In fact, prefab may play an even bigger role in the housing industry from here on, architects and builders say.

Read the entire article for more information.

The home page of Dwell Magazine currently features a 2005 article about a house in Wisconsin built using SIPs. It was designed by David Salmela of  Salmela Architect.

Salmela Architect.

The larger of the two units (which contains the kitchen, dining area, lounge, master bedroom, bath, and screen porch) is 900 square feet, and the smaller (where the guest room and bath, office area, and mechanical room are located) measures 360 square feet. The house, which was finished in 2003, cost $295,000 to build.

Read the entire article for more information.

The Wall Street Journal recently looked at 10 winners of residential design awards from the American Institute of Architects. 2 of them fit our "prefab and modular" focus.

From their slideshow:

Cinco Camp (pictured above) by  Rhotenberry Wellen Architects:

Rhotenberry Wellen Architects:

This house is made from five recycled shipping containers

Laidley Street Residence by  Zack/de Vito Architecture:

Zack/de Vito Architecture:

Most of the home's frame was fabricated elsewhere and assembled on-site, a process known as panelized construction

Read the article for more information, and see the slideshow for 10 of the 17 winners.

Hat tip: Arch Daily on April 20, 2009.

Neither source links to the original AIA press release that lists all 17 winners in 4 categories: One/Two Family Custom Housing, One/Two Family Production Housing, Multifamily Housing, Special Housing.

The Vancouver Sun recently featured an interesting proposal by architect George Henriquez (of  Henriquez Partners Architects) and real estate consultant Michael Geller.

Henriquez Partners Architects) and real estate consultant Michael Geller.

Vancouver city council is backing a proposal to provide 550 temporary housing units for the homeless, including prefabricated modular units

According to Geller:

capital costs would vary between $37,000 and $46,000 per unit, compared to $302,000 for permanent units already announced by the province

Read the article for more details.

Hat tip: PropertyProf Blog on April 16, 2009.

The Herald Sun in Australia reports that the first re-Growth pod by  1:1 Architects has arrived on site.

1:1 Architects has arrived on site.

They are available at a cost of $30,000, and can be built as single or multiple units and placed on almost any block in two weeks.

Read the entire article for more details.

Hat tip: Arch Daily on April 12, 2009 and the re-Growth pod blog on April 8. Both include pictures.

The Worcester Telegram & Gazette in Massachusetts recently featured Michelle A. Roberts, founder and creator of  EcoHealth Homes.

EcoHealth Homes.

Her opinion about modular homes:

“They are designed with detailed, engineered plans. And they are made in factories in a controlled environment where there are safe, happy workers,” Ms. Roberts said. “There are some gorgeous mansions that are modulars.”

Besides better quality, she said, modular offers fewer construction delays, a tighter building envelope and continuous inspection throughout manufacturing.

Read the entire article for more information about Ms. Roberts. Interesting note: she has been appointed to Governor Deval Patrick's Massachusetts Zero Net Energy Buildings Task Force.

The News & Observer in North Carolina highlighted a modular hybrid home.

Studio B adapted the prefabricated portions of the house into a simple, striking composition: modules on the ends, a recessed entry space in the middle and a single sloped roof capping it all. Three parts of the house were trucked to the site from a nearby factory and installed in one day.

...

Spanning the prefabricated modules...is the portion of the project that was built on site: the two-story living area

We found model information on the BuildSense website:

They also share a floorplan (PDF) that includes a series of construction pictures.

Read the entire News & Observer article for more information and check out their photo gallery.

The February 2009 issue of Dwell Magazine featured a concrete prefab in Switzerland by architect Felix Oesch.

it took nine months to build the house using a prefabricated panel system

...

Each panel is made up of two outer layers of 2.4-inch-thick concrete, which act as the bread of the sandwich. Inside there’s a core layer of concrete as well as seven inches of insulation. This means the panels, which arrived onsite with all the holes cut for the fixtures and fittings, are relatively light and easy to maneuver. Subsequently, construction was a question of fitting them all together like pieces of Lego.

Read the entire article and view a slideshow containing 11 pictures of the home.

Hat tips: StyleCrave on March 17, 2009 via materialicious on March 11, 2009.

Last week, Times Union covered a new 3-unit prefab building in Saratoga Springs, NY.

Highlights:

-

builder:

Westchester Modular Homes

Westchester Modular Homes

- designer: Phinney Design Group

- 4,200 sf, 2 stories

- the sections arrived in six boxes

- "saved 20 percent on building and loan costs by going prefab"

- built in 8 days in the factory (plus additional work to be done on site)

Over the next few months, workers will add custom porches, cupolas and other features to make the home fit into the area's Victorian streetscape

Read the entire article for details.

The New Republic recently discussed the plight of prefabricated housing in the United States.

Technologically, there is no reason why houses, like cars, cannot be mass-produced, and in other countries they are constructed that way. Prefabricated, mass-produced homes, like mass-produced cars, offer myriad advantages. Fewer resources, material and labor, are wasted. Weather does not dictate construction schedules. Higher and consistent quality is more easily and reliably achieved, because the product is fabricated in the controlled setting of a manufacturing plant, with all the attendant cost advantages.

Consistent with their political leaning, they call for government to step in:

For quality affordable mass-produced housing to be built, we need to create different conditions for a mass market. A new legislative structure must clear away the obstacles presented by non-standard, municipally controlled building codes and create enforceable national standards for prefab-friendly, environmentally responsible manufacturing and construction practices.

The article is quite long, but worth reading.

Hat tips: Building Systems on February 21, 2009 and Apartment Therapy on February 26, 2009. The latter has an active comment thread, with a general consensus that price remains a major barrier.

The Economist recently covered small houses.

The Small House Movement has been around for years, encouraging people to think about how much house they really need. But lately it has attracted more attention. “It seems like a perfect convergence of a bad housing market meeting a bad economy and more awareness about global warming,” claims Jay Shafer, an enthusiastic advocate.

The article mentions 2 companies, both with prefab options:

Read the entire article.

Hat tip: Jetson Green on February 23, 2009.

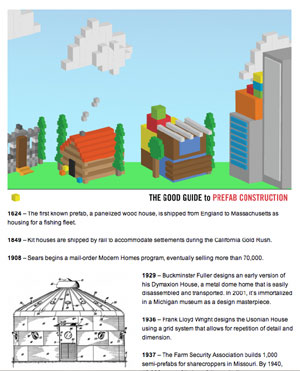

GOOD Magazine recently provided an interesting timeline of prefab history.

Did you know?

1624 – The first known prefab, a panelized wood house, is shipped from England to Massachusetts as housing for a fishing fleet.

They published a set of short articles as the GOOD Guide to Prefab Construction:

- Thinking Inside the Box

- A Sustainable Housing Solution?

- A Few Words From a Legend

- Prefab Financing

- Prefabs: Modular Vs. Kit

The New York times recently shared the winners of Live the Box: An International Design Competition.

According to the contest site:

AIA Newark and Suburban challenges the world’s most innovative thinkers and designers to re-invent the box with their most inspired and creative utilizations of shipping containers as the primary construct of an urban multi-family mixed use project.

They list the entrants and winners.

Read the NYT article for more details.

(Hat tips: TreeHugger on February 2, 2009 and Apartment Therapy Re-Nest on February 3, 2009)

The Cape Cod Times recently featured custom modular homes by  Realty Development Associates in Sagamore, MA.

Realty Development Associates in Sagamore, MA.

Modular home buyers now have a wide choice of fine features that rival those in stick-built homes, from tray and vaulted ceilings, to granite and marble tiles, carpet to wood flooring, maple or cherry cabinets, beadboard and paneled wainscoting and high-grade insulated windows.

Read the entire article for more details.

Back in October, The Guardian provided a gallery of pictures which they consider to be

the best green buildings from the design website Inhabitat

Note: Inhabitat is part of the Guardian Environment Network.

The gallery includes 3 prefab homes:

-

Cellophane House by

Cellophane House by  Kiernan Timberlake Associates

Kiernan Timberlake Associates

-

Redondo Beach house from

DeMaria Design Associates

DeMaria Design Associates

-

a flat pack project by

SYSTEMarchitects and

SYSTEMarchitects and  Gauthier Architects

Gauthier Architects

Hat tip: The Green Blog on October 20, 2008

Michelle Kaufmann Designs is receiving the 2008 TOP FIRM Award from residential architect magazine, so I am here to accept the award on the company’s behalf. It is quite an honor...

More from residential architect:

In the five years since she started her firm ... Kaufmann has made remarkable progress in achieving this mission. Michelle Kaufmann Designs (MKD) has built 33 green, modular homes to date, mostly on the West Coast.... Thirty employees buzz busily around the firm's Oakland, Calif., headquarters, which possesses the same design sensibilities as its houses: clean lines; simple, yet high-quality materials; and an overall sense of calm and order.

Since 2006, the firm has built many projects in its own factory, mkConstructs, in Lakewood, Wash.... "Now we're taking what we've learned in all the construction phases and applying that to our designs," says Paul Warner, AIA, a principal at MKD.

Read the full article for details.

The Boston Herald recently reprinted an Associated Press article about a modular classroom built by Project Frog.

it's a demonstration of how modular construction can be used to construct green buildings cheaper, faster and better.

The classroom was built as a part of the Greenbuild International Conference & Expo which was in Boston last week.

Project Frog ... uses modular building to offer affordable enviro-friendliness — [Mark Miller, the company’s chief executive officer] says its buildings are 25 percent cheaper than traditional construction, though more expensive than normal modular buildings... "I think it’s a huge and neglected part of green building," said [Miller].

The article listed a number of advantages of modular construction, including:

- each piece of the home can be specially designed and fitted, using materials produced with the least environmental impact for maximum energy efficiency and health - each component — the kitchen, the wiring — can be tested for quality in a factory away from the wind and rain

But also recognized the many challenges: (some we agree with, others we don't)

- perception of being cheap and ugly

- Americans generally remain skeptical about the quality of buildings

- standardization can be a drawback ... because most people want to custom build

- limited by relatively few modular building producers

- difficulties transporting the sections to some tightly packed areas

- nature of the housing market, in which most people remodel existing homes, rather than build new ones

Miller is hopeful despite the current housing market:

I can almost guarantee you that at the end of this, green building will still be around, and will probably be kicking up even more, and modular will still be around and be kicking up even more.

Read the whole article for more details, including interviews with:

- Art Breitenstein of All-American Homes

- Carlos Martin of the National Association of Home Builders

Coverage of Project Frog on other blogs:

- Treehugger on November 20, 2008

- Jetson Green on November 22, 2008

The New York Times follows up on the Resolution: 4 prefab in the Bronx that they covered back in February.

After years of living with their son in a 900-square-foot bungalow, Regina and Bill Marengo wanted a bigger place.

Ms. Marengo, a civil engineer, hit on the idea of ordering a prefabricated house. If it could be built in a factory and transported to the site, she reasoned, the family could trade up with minimal disruption.

Which proved to be true:

[the] Marengo’s move to their relatives’ house in Morris Park, the Bronx, lasted only four months; with on-site construction it would have been far longer.

The cost?

The Marengos said they paid about $200,000 to Simplex and slightly more than that to Northside Construction.... For designing the house, the firm Resolution: 4 Architecture received 15 percent of the overall costs.

Read the full article for more details about Resolution: 4 and the construction process.

A few weeks ago, the Aspen Times featured a number of high-end modular construction projects happening around the Aspen, CO area.

some modular home companies...“can make those [modular houses] look like all the other fancy custom homes in the valley,” and in certain cases they can do it quicker and for less money, according to Steve Bossart, a project manager with the city of Aspen who is familiar with ongoing studies into modular technologies.

They mention the following companies:

- Bar Vista Homes (no website found)

-

Studio B Architects

Studio B Architects

-

Timber Creek Homes

Timber Creek Homes

-

WeberHaus

WeberHaus

Read the full article for details.

A recent article at Forbes.com looks beyond the current downturn:

When U.S. housing recovers, the leading homebuilders may not be the ones to benefit.

Instead:

Humble creators of manufactured housing. Not only are these low-end homes more in keeping with the spirit of the times than mutant McMansions, they look much better than the double-wides of yore and subsidy-happy Uncle Sam is about to include them under the aegis of its favored lending programs.

According to the article:

Starting in April [2009], the Federal Housing Administration is increasing loan limits to $70,000 from $46,000 when only the manufactured home -- and not the property beneath -- is being financed.

FHA loans are becoming hugely popular:

...because they are essentially the only low-downpayment loan offering available...There is no income ceiling or credit floor on an FHA insured loan. A borrower just needs to come up with a 3.0% downpayment and prove sufficient income to pay back the loan.

We previously covered the difference between manufactured (HUD code) and modular (regular code) homes.

Read the article for more details.

We're still catching up on news from last month. Here's a story worth covering:

Homes for Our Troops is a non-profit organization that provides homes to military personnel with severe injuries or disabilities sustained in active-duty wartime. Tidewater Modular Homes of Virginia Beach teamed up with Nationwide to provide the house for Bartlett, which will be set on its foundation in Chesapeake on Veteran’s Day Nov. 11.

Bartlett, who lives in Norfolk, came to Martinsville on Wednesday for a reception at Nationwide. He toured his future home in progress, stepping through the rooms on a $110,000 pair of prosthetic legs.

His new modular home is 1,475 sf and handicapped-accessible.

Some links:

- more details

-

Tidewater Custom Modular Homes is the local builder

Tidewater Custom Modular Homes is the local builder

-

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

- Homes For Our Troops accepts donations

(Hat tip: Charles Bevier of Building Systems on October 24, 2008)

The goal of prefab is clear:

For more than a century, architects and builders have strived toward a prefabricated, industrialized house, one made in a factory so that economies of scale would be realized and the product would be affordable to all home buyers.

It's worth remembering that the current "stick built" process was itself an important innovation, "prefabricating" the basic components:

Until the 1830s, most houses in America were built with post and beam framing. All the pieces were hand-hewn and held in place with complex joinery, and home building was a time-consuming, costly process. Around then, however, steam-driven saws that could produce large quantities of accurately sized building lumber and machines that made huge quantities of iron nails began to appear in the larger cities.

An enterprising Chicago building contractor, George Washington Snow, saw the potential for these new products to revolutionize the building industry. He devised a method of framing that was much faster and far less costly.

One step forward in the meantime: panels (6% of homes built in the US in 2007).

the 2-by-4 stud walls sometimes are assembled in factories and hauled to a job site, an approach called panelizing.

A bigger step: modular (3% of homes built in the US in 2007).

a method of building in a factory an entire conventional wood-framed house in sections, loading each one onto a flatbed trailer, trucking it to a job site and then setting it in place with a crane.

Read the whole article for a few details on pros, cons, and possible futures.

Last month, The Daily Telegraph in the UK compiled a list of prefab products, describing them as

a burgeoning crop of 'instant' homes that take the prefab to a whole new level.

Included on the list:

| model | designer | ||

|---|---|---|---|

| The Loft Cube | Werner Aisslinger | ||

| 39-55 sq m (420-592 sf) |

£63,500 - £88,500 ($95,496 - $133,042) |

||

Micro Compact Home Micro Compact Home |

Richard Horden of  Horden Cherry Lee Horden Cherry Lee |

||

| 2.6 m cubic units (8.53 ft) |

about £26,000 ($39,086) excluding installation |

||

| Homes 2 Go | Dutch company Spacebox, brought to Britain by Benfield ATT Homes | ||

| 18 sq m (194 sf) |

£22,950 ($34,500) excluding delivery |

||

| Weberhaus | |||

| 200 sq m (2,153 sf) |

from £300,000 ($450,990) | ||

M-house M-house |

Tim Pyne | ||

| 100 sq m (1,076 sf) |

£147,500 ($221,736) | ||

| Eco Pod | Aidan Quinn of Eco Hab | ||

| 28 sq m (301 sf) |

£30,000 ($45,099) | ||

Read the full article for pictures and further details.

Two weeks ago, the Christian Science Monitor featured Everhouse, a simple design meant to address the post-hurricane housing shortage near the Gulf Coast:

700,000 homes damaged ... and 250,000 homes destroyed

The designer of Everhouse looked to the advantages of prefabrication to help.

To keep costs down, the components of an Everhouse are made by a factory in Palatka, Fla., and then delivered to the land where each unit will be built. And like a desk from Ikea, the pieces arrive with all the necessary materials included...

They opted for a “panelized” design, because the concrete panels are easy to transport and give both the designer and homeowner a good amount of flexibility in house plans.

Key benefit: the shell can be assembled in one day.

The company hopes to produce 1,500 homes per year.

Sawyer also sees a shortage of skilled construction labor in the region. Read the article for his proposed solution.

Last month, the San Francisco Chronicle published an article on West Coast Green's showhome, the Harbinger House from  SG Blocks LLC:

SG Blocks LLC:

What makes this year's showcase home different from the prefab modular model seen last year [MKD's

mkLotus] in San Francisco is not all the green bells and whistles ... it's the actual framework of the house that is truly innovative. This year's showstopper is made from five 40-foot-long shipping containers that once roamed the high seas

The article repeated a comment we've seen a few times:

a layman can't tell that, underneath its sleek lines, Harbinger was once a collection of lowly shipping crates

The advantages of shipping containers?

They're made of heavy-gauge steel, which holds up nicely in a hurricane or earthquake, but is usually too expensive to use in construction. [SG Blocks] gets the containers cheap - $500 to $2,000 a pop - because the fuel costs to ship them back empty to China or other places overseas are prohibitive. Because of the United States' huge trade imbalance, there are many empty containers lying around.

Harbinger details:

- made from 5 shipping containers

- 2 stories

- 1,700 square feet

- about 5% less expensive than building in wood or other conventional materials

- can be built 40% faster

SG Blocks facts:

- founder: David Cross

- location: St. Louis

- has built 6 single-family homes in the US (designed by Lawrence Group)

- 400-unit elder-care facility in Oceanside, CA will be unveiled soon

On the New York Times' Freakonomics blog, Annika Mengisen wonders whether prefab will ever catch on. For answers, she questioned two authors of prefab books, Allison Arieff and James Trulove.

Here are the questions posed; read the full post for their answers.

- Where do prefab houses stand in the U.S. real estate market?

- What, if anything, is the housing crisis doing to prefab?

- What would push prefab beyond a niche market?

- If prefab did catch on, what would the economic implications be?

- What does prefab do for the environment?

- What could prefab do for storm-prone areas?

A blog called Greenlight has some interesting news:

The Japanese electronics giant has assembled a strategic plan to start making modular homes in about three to five years that will combine green construction along with sophisticated electronics to curb energy consumption.

While the energy savings ideas are new, Panasonic "already has a construction division that makes modular homes in Japan."

Though not likely to be coming to the US anytime soon:

the U.S. could be the last market it approaches...

Architectural Record reports:

From October 17 to 30, a temporary prefab “neighborhood” in Philadelphia will offer an optimistic view of what a revitalized city might look like in the near future. A Clean Break, curated by Minima Gallery, will be a central event of DesignPhiladelphia, an annual series of lectures, studio tours, and exhibitions organized by the Design Center at Philadelphia University.

The show will feature two actual prefabs:

Also in the exhibition:

renderings of residences designed by Gans Studio & dArchitects, Studio 804, and Interface Studio Architects ...

The exhibition is free and open to the public.

This month's Conscious Choice, "an enlightened urban lifestyle magazine," examines Prefab 2.0 in a recent article:

Judging by magazines, museums and word of mouth, you might think we were in a prefab housing Golden Age.

You’d be wrong — but not by much. Yes, prefab housing is getting more attention than it has for decades. And yes, beautiful prefab homes are on display at museums and design exhibitions. But just because they’ve built them doesn’t mean homeowners are coming in droves. Instead, only about 100 homeowners live in prefab homes in the U.S....

(One quibble: the estimate of 100 is only true based on a narrow definition, e.g. modernist prefab built in the last few years. We take a much broader view of prefab.)

The article included several profiles from around the US:

Chicago, Illinois

Prefab is an interesting idea and like any good academic, Chris Conley wanted to put the theory to a test. So when he and his family set out to build a weekend home in Libertyville, they decided to be their own guinea pigs.

Designer: the homeowner, Chris Conley

Venice, California

The one-story house has turned out to be the home of their dreams. The house came out on time and on budget.

Designer: Jennifer Siegal of  Office of Mobile Design

Office of Mobile Design

Seattle, Washington

He was so convinced prefab was the future that he and his partner Bill Shepherd bought some land on Whidbey Island to try one out.

But if his experience is any example, prefab may not yet be ready for prime time.

Designer:  Rocio Romero

Rocio Romero

New York, New York

Logistically, they were hoping that building the house in the factory would save time and money. But it didn’t quite work out that way, says Morrow. Getting the permits and doing the finish work, like building a screened-in porch and attaching the four modules to one another, took the same amount of time as any other house.

Designer:  Resolution: 4 Architecture

Resolution: 4 Architecture

San Francisco, California

"We wanted high-quality and enduring style," says [homeowner] Haney. "What we weren't prepared for was the quality of the house. I have built several houses and this is by far the best quality home I've ever lived in. It's fabulous. When you build on-site, there's little quality control. The individual contractors are all supposed to do their jobs, but the overall aesthetic is almost left to chance. In a factory, you have quality control at every step."

Designer:  Michelle Kaufmann

Michelle Kaufmann

Read the full article for additional details.

On Wednesday, The New York Times filed a pair of articles on small homes. The first, specifically covered prefab sheds:

Tiny, high-style prefabricated sheds like the Kithaus have received a great deal of attention over the last year, with admiring coverage in design blogs and magazines, and roughly four times more companies producing them now than five years ago. So far, the market is still small, though a tipping point of sorts may have been reached this year, when Design Within Reach began selling the Kithaus, along with furnishing packages to turn it into an instant office, bedroom, pool house or den.

Companies and models included in that article:

The second explained the "tiny house" phenomenon:

... spaces that are smaller than 1,000 square feet and, in some cases, smaller than 100. Tiny houses have been a fringe curiosity for a decade or more, but devotees believe the concept’s time has finally arrived.

Prefab models mentioned:

An interesting story from Ball State University in Muncie, Indiana:

Michael Gibson recently finished a building prototype that utilizes prefabrication techniques in a way that has never been done before....

Gibson's plan included two standard prefab walls and two experimental walls he called lattice walls that were made of plywood instead of the standard dimensional lumber, which he said wastes materials. The lattice walls also used less material because of an assembly form called nesting, in which several lightweight boards nest together in a V-shaped fashion.

"The beautiful thing about the lattice walls and how they nested together was that they used less nuts and bolts," Gibson said. "They were also very lightweight, and the pressure from the roof was pretty evenly distributed, which prevented the structure from racking."

Most of the companies we track use a small number of accepted framing techniques. Some use SIPs:

Others use traditional framing (whether wood or steel):

-

Rocio Romero

Rocio Romero

-

Marmol Radziner

Marmol Radziner

-

LivingHomes

LivingHomes

-

Alchemy Architects

Alchemy Architects

-

Empyrean International

Empyrean International

-

Hive Modular

Hive Modular

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

And a few use unique metal framing systems:

Worth noting: the plywood framing system used in the  BURST* model, currently on view at MoMA's Home Delivery show, used a similar plywood framing system.

BURST* model, currently on view at MoMA's Home Delivery show, used a similar plywood framing system.

The Washington Post discussed MoMA's Home Delivery show earlier this week, leading with a quite provocative line:

The architect who masters prefabricated housing -- how to make homes that are well designed, mass-produced, affordable and easy to build -- may well go down in history as the Last Architect.

Got my attention, at least. The article continues with the prodding:

As a fascinating and important new Museum of Modern Art exhibition, "Home Delivery: Fabricating the Modern Dwelling," makes clear, they have mostly failed. But if anyone ever succeeds, perhaps the grand challenge of domestic architecture would be over -- time's up, pencils down.

The article makes many such observations and poses a few questions:

The paradox of the prefab dream, which began with proles in boxes, is that it lingers in the bourgeois craving for luxury goods and second houses.

And so does prefab turn out to be just another designer accessory, not so different from Louis Vuitton handbags or Prada shoes, industrial status symbols that are basically the same from unit to unit? Is it true once again that the blessings of modernism, supposedly a gift for the many, are really just a prize for the few?

Some specific thoughts on the homes in the show:

the ridiculously small confines of the Micro Compact House will [not] leave you with any desire to live there.

the System3 project ... is a compelling piece of architecture by any standard.... Stand in the System3 for a few moments, and you want to live here.

In summary:

"Home Delivery: Fabricating the Modern Dwelling" will leave you honestly conflicted, dubious about where history has brought the prefab dream. And more than ready to move into a prefab castle, just as soon as you can buy a nice plot of land and muster the down payment...

What do our readers think about The Posts's observations? Have most of prefab's early practitioners failed? Is prefab just a "prize for the few?"

While reading the full article, be sure to check out the accompanying slideshow.

The Christian Science Monitor took a look at modular homes last week, focusing on the green qualities:

This summer, two exhibitions of modular houses – at Chicago’s Museum of Science and Industry (MSI) and New York’s Museum of Modern Art (MoMA) – are putting a spotlight on how off-site building techniques can shrink the carbon footprint of a new house.

The article cites a number of reasons why building in the factory is a good idea:

- finish construction usually takes a few weeks, not months, saving energy by requiring fewer trips to the job site by construction workers

- by building indoors, workers can also more easily make sure that energy-saving features like insulation are carefully and properly installed for maximum effectiveness

- individual home-building companies may not have the resources to keep current on the latest "high-performance building" techniques ... but modular homes can have state-of-the-art environmental design built into them at the factory

The companies mentioned in the article:

-

KieranTimberlake Associates

KieranTimberlake Associates

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

-

HOM Escape in Style

HOM Escape in Style

- Envision Prefab

- Cardinal Homes

Read the complete article for details.

Very interesting -- though apparently not headed to the US. From an article in the Wall Street Journal:

Best known for its top-selling cars like the Prius and Corolla, Toyota is looking to apply its ecofriendly image and technical know-how to help boost sales of its small and little-known prefabricated-housing division.

Unbeknownst to most of us, Toyota prefabs have been around for awhile:

Since 1975, Toyota has been building steel-frame houses designed to withstand earthquakes and typhoons and keep out burglars.

The tie-in with Toyota's vehicles is certainly interesting:

Toyota's aspirations as a home builder are also gaining new importance with the planned launch by 2010 of its plug-in vehicles, gas-electric hybrid cars with powerful lithium-ion batteries that drivers will need to recharge at home. The car maker is testing an electricity-monitoring system in its homes that would charge the vehicle during off-peak hours to keep utility bills low, while the car's battery can serve as an electrical backup, powering the home during blackouts.

I can't help but quote this imagery:

At the Kasugai Housing Works in central Japan, one of Toyota's three prefab-housing factories, an assembly line of robots, conveyor belts and helmeted workers produced a steady flow of rectangular steel-framed cubicles finished with staircases, kitchen cupboards, bathtubs and toilets.

The timeline sounds right:

Most Toyota homes are made from six or more of these large cubicles, which are assembled -- like Legos -- on the building site. From its start on the factory floor to its final completion on site, a Toyota home can be built in 45 days, less than half the time it takes for contractors to build a typical wooden-frame home, Toyota says.

Alas:

Other than what it called a one-time "experiment" building a development of 50 homes near its truck plant in San Antonio in 2006, Toyota says it has no ambitious plans to build homes outside Japan.

The company's past sales leave much room for expansion, within Japan and abroad:

- 5,000 units in 2006

- 4,600 units in 2007

I couldn't find an official Toyota Homes Website, just this little tidbit from Toyota's homepage.

Read the whole article for some housing issues that are specific to Japan.

A busy week!

Inhabitat's Prefab Friday enjoyed Method Homes' cabin:

we’re happy to report that Method Home’s modern wood wonder has blossomed into a beautiful home.

Inhabitat also covered HOM:

Simple, purposeful, ecological and crafted, HOM houses are meant as secondary residences; a HOM away from home to which busy urbanites can escape in style.

Jetson Green wrote about a container home in San Francisco, designed by Leger Wanaselja Architecture:

It's a simple design that shows what [is] possible with innovative home construction.

Visit Jetson Green for the full post and a bunch of photos of the home. The previous day, Preston previewed the West Coast Green showhome:

It's a 1700 sf container home, but you probably can't tell just by looking.

We'll cover West Coast Green and the showhome in more detail soon.

And a little more news on MoMA's Home Delivery show. New York's The Villager discussed the show:

“Home Delivery" ... is a coup for quality. It’s also a tour of prefab past, a spiffy toy store of drawings, models and actual toys from the century-plus history of industrialized home construction.

Business Week reran a short article from Architectural Record on the show:

One of New York's most exciting cultural venues this summer is a vacant lot in Midtown Manhattan....

Moco Loco ran a series of posts on their favorite three homes in the show. They introduced the show Monday. On Tuesday, they covered the  System3 house:

System3 house:

Inside, its austere bearing gives way to a more luxurious simplicity...

Wednesday's post featured an interview with Cellophane House designer James Timberlake:

What will happen to this particular home on October 21? We are working on this concurrently with the show. We have discussed the possibility of auctioning the house.

Thursday's post looked at  BURST*:

BURST*:

But marveling at the architecture is not the point of BURST*. Ultimately, the structure puts the emphasis on nature: The house’s rear elevation unfurls in a cascade of bleacher-style seating, all the better to sit and enjoy the view—out.

Last week, The Houston Chronicle took an in-depth look at Zamore Homes.

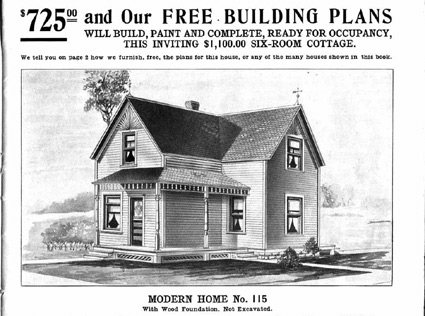

When Sears started selling kit houses by mail in 1908, the company promised that a man of average abilities could assemble any of the models in the catalog — from a small gabled cottage to a roomy Dutch colonial....

Exactly one century later, Houston architect Brett Zamore is bringing kit homes back.

Zamore assumes that the average man or woman of today has neither the desire nor the ability to assemble a home. That's why Zamore Homes will gather the materials, coordinate delivery and manage the construction process....

Some homes are local:

Zamore is just finishing construction on three kit houses in Houston's West End, on Center near Thompson.

Some not:

Mississippi native Karen Parker ... mother of six lost her Biloxi home to Hurricane Katrina ... selected Zamore's design and finally moved into her 1,400-square-feet home this past January.

The article provides a good working definition of "prefab":

In the strictest terms, prefabricated homes are built and assembled in a factory and then shipped to the property. In a larger sense, the term could also apply to homes with prefabricated parts that are assembled on site.

Zamore Homes models fall into the latter category.

In all, there are seven designs, in sizes that reach 2,200 square feet. But the KIT05 can grow as large as the homeowner wants.

Here's the models and specs from the Zamore Homes site:

- KIT00: 400 sf, 1 bedroom ("little casita")

- KIT01: 992 sf, 2 bedrooms

- KIT02: 1,250 sf, 2 bedrooms

- KIT03: 2,000 sf, 2 bedrooms

- KIT04: 2,200 sf, 3 bedrooms

- KIT05: varies

- KIT06: 1,300 sf, 3 bedrooms

- KIT500: 504 sf, 1 bedroom

Compared to local costs in the Houston area:

... new construction going for $130 to $170 per square foot.

The pricing sounds quite competitive:

Zamore's kit homes cost between $110 and $150 per square foot, which includes hard and soft construction costs. [information on hard vs. soft construction costs]

Here's our quick comparison to other kit homes:

| Company | Models | Materials supplied | Advises |

|---|---|---|---|

Rocio Romero Rocio Romero |  LV Series LV Series | only the walls and roof framing | windows, finishes and other materials |

kitHAUS kitHAUS |  k3 k3 | everything except interior fixtures (plumbing, lighting) | None |

Jeriko House Jeriko House |  Jeriko House Jeriko House | all finishes | None |

The materials and finishes page on the Zamore Homes site is worth a look.

Read the full article for more details.

Listen (~16:00) to a broadcast from New Hampshire Public Radio about the show, featuring an interview with Stephen Kieran of  KieranTimberlake Associates.

KieranTimberlake Associates.

Bloomberg Television's James Russell reviewed the exhibition:

... a wildly ambitious display of the pleasures and peculiarities of prefabricated houses. The prototypes, augmented inside the museum by a rich history of the genre, capture both the earnestness of architecture's obsession with industrial technique and its faith in technology as an agent of progress.

Read the whole thing for some specific criticism -- and possible upside.

USA Today offered an overview:

an engrossing survey of the prefab movement...

The New York Times profiled  BURST*08 and architects Jeremy Edmiston and Douglas Gauthier. The path to realizing the home was not an easy one:

BURST*08 and architects Jeremy Edmiston and Douglas Gauthier. The path to realizing the home was not an easy one:

... arranging all the parts into the right piles so they could just be snapped into place at MoMA turned into a logistical nightmare lasting weeks rather than days. While they sorted, the 15 or so architecture students on hand were trying to reassure the contractors about a model that looked as sturdy as a collapsible fan. As for the architects, they were running back and forth to their offices, scrambling to update the drawings and struggling to raise money.

The full chronicle of the home's construction is worth a read, but sadly, it sounds like we won't be seeing future prefabs from the pair:

For the two architects, however, the success is bittersweet. After nine years their partnership has ended. “This is our last project together,” Mr. Edmiston said.

New York Magazine's architecture critic also reviewed the show:

This sporadically exciting but ultimately diffuse show begins indoors, on the sixth floor, and sidles up on the present by way of the past. It opens, brilliantly, with both....an exhibit that can’t quite decide whether prefabrication should be treated with irony or exuberance.

The New York Times architecture critic provided a glowing review of MoMA's Home Delivery in this morning's paper:

"Home Delivery: Fabricating the Modern Dwelling," which opens on Sunday at the Museum of Modern Art, is a delightful surprise....In a tour de force Mr. Bergdoll [the show's curator] was able to build five full-scale model houses for the show in a lot just west of the museum. The effect is startling: expressions of a suburban utopian world surrounded by Midtown’s looming skyscrapers.

Mr. Bergdoll has not only managed to track down some unexpected gems, he has also arranged them in a way that allows us to see them with fresh eyes. He makes a convincing case that prefabricated housing was both a central theme of Modernist history and a dream that remains very much alive today.

We've provided extensive coverage of the full-scale homes; this review adds details on the accompanying exhibits:

[the show] presents more than 80 projects, from humble experiments in suburban living to stunning works of cretive imagination.

Here's a sample: (plus some external links we dug up)

- wall fragments from architects Rahim, Hina Jamelle, Jesse Reiser and Nanako Umemoto

- One Week: "a 1920 Buster Keaton film in which fumbling young newlyweds try to assemble a prefabricated house"

- the Manning Portable Cottage: an 1833 prefab that "could be conveniently packed in a ship's hold and reassembled."

- the 1931 Copper House: "designed by the Modernist master Walter Gropius. It was conceived as a system of insulated copper wall panels that could be easily transported and assembled on site in 24 hours."

-

Jean Prouvé's Maison por l'Institutrice: "a reworking of his 1948

Maison Tropicale, a masterpiece of prefabricated design."

Maison Tropicale, a masterpiece of prefabricated design."

- the Lustron House: "modern technology draped as nostalgia"

- Archigram's 1965 Living Pod: "an amoeba-shaped capsule with mechanical systems plugged into the side"

- Kisho Kurokawa's Nakagin Capsule Tower, which was slated for demolition last year

- Primitive Huts by Wes Jones

- works from Greg Lynn and Teddy Cruz

- Thomas Edison's Simple Concrete House System

Read the full article for more details and a new slideshow with 12 images.

One correction to the article: the frame of the  Cellophane House is aluminum not "lightweight steel."

Cellophane House is aluminum not "lightweight steel."

We've previously mentioned Mississippi's Safeway Homes in regards to their strength and affordability. The Sun Herald ("Southern Mississippi's Newspaper") explains further:

Modular homes built in north Mississippi are the first in this state to receive a Fortified Home designation that qualifies the owner for...insurance discounts once the home is properly installed.

"The desire was to build a home that was very strong, but also very low-cost to maintain," said Dan Hobbs, CEO of Safeway Homes in Lexington, Miss. "The whole purpose was to build excellent quality work-force housing. It's cost-efficient housing."

Some specifics about how the Fortified Home program works:

Safeway Homes are designed to withstand 150-mph winds. While the design has received Fortified Home approval, the designation is awarded only after certified personnel have completed foundation and final inspections to ensure each home is properly and permanently anchored, and meets elevation requirements.

To learn more about the "Fortified...for safer living®" program, visit the Institute for Business & Home Safety site. Read the full Sun Herald article for more details on Safeway Home's designation.

We've covered the Empyrean NextHouse in Silicon Valley before; here's a new story about the home from the San Jose Mercury News:

The 2,400-square-foot house was built in panels by manufacturer Empyrean at its factory in Acton, Mass., shipped to the Bay Area and assembled on-site. It incorporates energy-efficient technology and sustainable materials and is the seventh in a series called the NextHouse; the project has been a collaboration with San Francisco-based Dwell magazine, which has 12 more under way across the country.Lots of people think prefab equals one-size-fits-all.

"Prefab is somewhere in the middle between the builder home, which is like a pair of jeans that's made for the average person, and the custom home, which is like a couture item," says Sam Grawe, editor in chief at Dwell, which has been promoting modern prefab architecture since its debut more than seven years ago.

"Prefab gives you the opportunity to design your own home but also has the efficiencies of the builder's model."

Via the American Chronicle:

...This Old House partners with custom homebuilding company, Bensonwood, to build a new timberframe home.... Cutting-edge techniques, including extensive uses of prefabrication and green technologies, will be implemented to construct a new home on property owned by the Favat family in Weston, Massachusetts....As both the architectural firm and prefabricator on the project, Bensonwood will build 75 percent of the house in a controlled workshop environment. Entire wall systems and room modules will be built, outfitted for plumbing and wiring, with windows and finishes added, in many cases, right in the workshop. Additionally, the timberframe will be created using traditional hand-craftsmanship, as well as the latest computer-aided woodworking technology, providing a level of structural integrity that will last hundreds of years. Many of the home's components will be assembled onsite by crane over a three-week period in early June....

Thisoldhouse.com will feature progress of the Weston project 24/7 through four Webcams powered by EarthCam....

More info on Bensonwood is available at their website.

Also worth a mention: This Old House has a blog, Old House My House, which will be a great place to keep track of the progress of the Weston prefab.

Back in March, Maryland's Gazette.net reported:

Amid today’s gloom and doom in the housing industry, Vince and Stephanie Scuderi are happy — finally — to talk about building their dream home.They chose a modular home design, an alternative construction method that can save time and money....

The house was together within hours, with all the major workings in place, including framing, drywall, roofing, plumbing, electrical wiring, cabinetry and trim.

‘‘The only problem sometimes raised by the homeowner is that they see it assembled in one or two days, then wonder why it takes another 90 to 120 days to finish,” Dean said. After assembly, much work remains, including well, septic and other utility hookups, porches and decks, driveways and landscaping.

Manufacturer: North American Housing Corp.

The full article has more details and images.

The Santa Cruz Sentinel reports:

Technology entrepreneur Philippe Kahn has taken home construction, environmental stewardship and style to a new level.Kahn ... had his new home near the Santa Cruz Small Craft Harbor trucked in from Los Angeles.

The prefabricated house was delivered last week in 18 pieces, each wrapped in white plastic and stored in the harbor parking lot. By today, the pieces, made of steel and glass, will be fit together like a puzzle to make a 3,200-square-foot, three-bedroom home on Fairview Place....

Kahn's home was constructed by Marmol Radziner, a Los Angeles architectural firm that specializes in custom, green modern homes built with prefabricated technologies.

Read the full article for more details and additional photos.

This article is too good to excerpt. 14 questions; interesting answers. Go read it!

We previously reported on Frank Lloyd Wright's prefab Duncan House. The New York Times travel section picks up the story:

We were inside the work of the master. Like any Frank Lloyd Wright house, this one was immediately recognizable.And briefly, it was ours. The Duncan House is a vacation rental, one of half a dozen Wright houses where paying guests can move in for a weekend or a few days and pretend to be home.

Read the full article for details on the other Wright houses (though the Duncan house is the only prefab).

We've covered prefab hotel rooms in Amsterdam. Now Reuters UK reports:

You see a vacant east London building lot paved over with asphalt and used as a car park. Tim [Pyne] sees the site of a rack-'em, stack-'em prefab temporary designer boutique hotel.An architect with years of experience designing temporary buildings for exhibitions, [Pyne] says prefab is the answer for a city like London, where quick development means a shortage of space, and shabby areas are suddenly chic.

His design is called the M-Hotel and it consists of a steel frame with trailer-style mobile homes fitted out with designer furnishings, stacked four high...

Jetson Green says:

I love the possibilities and ideas ... it's cool and innovative. The m-hotel is designed as a series of steel-framed slot boxes that slide into the frame (which makes for easy dismantling in the future).

Also from Tim Pyne: The  m-house.

m-house.

We reported last year on retailer IKEA's prefab homes. More from The Guardian:

Britain's first "Ikealand" opened its metal-panelled pine doors yesterday in an experiment designed to spread the company's off-the-shelf principle from wardrobes and sofas to entire houses.The first of 93 flatpack homes designed and equipped by the household goods store went on show in Gateshead on Tyneside, where scores of would-be buyers are being vetted to ensure that their savings and income are modest enough to qualify....

Prices on the cul-de-sac off Marigold Avenue, where each unit comes with 22 Skimmia shrubs and an apple tree in the garden, range from £99,500 [$198,000] for a one-bedroom flat to £149,000 [$295,000] for a three-bedroom house...

Treehugger adds:

Seen as a way for them to get onto the property ladder, these houses will sell for $260,000 for a two bedroom townhouse. Assembled in a factory nearby, they get to the site ready to be bolted together and take about 16 weeks from start to completion.The system is called BoKlok (Ikea speak for smart living) and was developed in conjunction with Ikea.

I did a little research on prices in the area; these look competitive.

From last month's Boston Globe:

...a three-bedroom, 2-bath home built in pieces in a factory and assembled onsite in less than a day - opens to the public today...It is the latest output from PowerHouse Enterprises, a Lawrence company out to extend the conventions of "eco-friendly" to include economical as well as ecological aspects....

The full article has the details.

The New York Times reports:

The social event of the season in Locust Point, a quiet enclave of tidy family homes along the East Bronx waterfront, took place just over a week ago when a crane lifted two 18-ton halves of a prefabricated house off flatbed trailers and stacked them like Legos on an empty lot....Resolution 4: Architecture of Manhattan...designed the Bronx house...

Joseph Tanney, a partner in the firm, was approached in 2005 by Regina Marengo, president of an engineering consultancy company, about putting a modern prefab on the Bronx waterfront property where she and her husband, William, had lived in a bungalow for two decades.

Read more about the  Resolution: 4 Architecture prefab in the full article.

Resolution: 4 Architecture prefab in the full article.

(Hat tip: Prefab Dweller)

A few of our favorite blogs posted round-up posts at the end of last year. Materialicio.us listed their top 25 stories of 2007, including a number of great prefabs. Jetson Green covered his most popular articles.

We were inspired to review our posts, clean-up the tags and share some highlights -- even if a bit late. First up, our favorite prefab news articles from last year.

From major US newspapers:

The New York Times wrote about prefabs as second homes.

The New York Post wrote about modular homes.

The Los Angeles Times discussed

OMD and the

OMD and the  Swellhouse.

Swellhouse.

The

Loblolly House appeared in the Washington Post and the Philadelphia Inquirer.

Loblolly House appeared in the Washington Post and the Philadelphia Inquirer.

Local papers:

We followed the replacement of FEMA trailers with modular homes.

Looked at modular homes in Long Island.

Covered modular homes in Mississippi.

And saw that modulars can be any size.

And more:

August brought Witold Rybczynski's Prefab Fad article. We disagreed.

In October, we got excited about bringing the factory to the site and a pretty cool prefab penthouse.

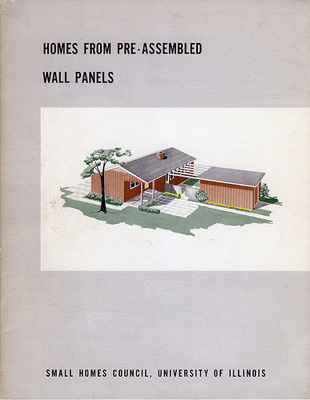

Core 77 reports:

Before pre-fab became so fabulously fab, the Small Homes Council at the University of Illinois in Urbana, Illinois published Homes From Pre-Assembled Wall Panels in 1954.

A bit more about the Small Homes Council, now known as the Building Research Council:

For over 50 years, BRC (formerly known as the Small Homes Council) has conducted housing research and provided public service to residents, homeowners, builders, contractors, engineers, architects, and others in the housing industry. Today BRC continues to draw on the expertise of its own staff and a campus-wide network of experts to improve the state of our built environment.Current research projects include studies on building performance, moisture control, toxicity issues in residential building materials, windstorm resistance, diversity issues in the architectural profession, and housing environments design and evaluation.

We could not locate the book on AbeBooks.

Still employing similar techniques:

•  LV Series

LV Series

•  Modern Shed

Modern Shed

The New York Times reports:

...the Museum of Modern Art has commissioned five architects to erect their own prefab dwellings in a vacant lot on West 53rd Street, adjacent to the museum. Whittled down from a pool of about 400, the five architects are participating in “Home Delivery: Fabricating the Modern Dwelling,” an exhibition opening in July.The five, to be announced today by the museum, are KieranTimberlake Associates of Philadelphia; Lawrence Sass of Cambridge, Mass.; Douglas Gauthier and Jeremy Edmiston of Manhattan; Oskar Leo Kaufmann and Albert Rüf of Austria; and Richard Horden of Horden Cherry Lee in London.

The MoMa site fills in some blanks:

This exhibition will offer the most thorough examination of both the historical and contemporary significance of factory-produced architectures to date. With increasing concern about issues such as sustainability and the swelling global population, prefabrication has again taken center stage as a prime solution to a host of pressing needs. The prefabricated structure has long served as a central precept in the history of modern architecture, and it continues to spur innovative manufacturing and imaginative design....The exhibition will examine this phenomenon through historical documents, full-scale reassemblies, and films that trace the roots of prefabrication in the work of architects including Frank Lloyd Wright, Jean Prouvé, and Richard Rogers, corporations such as Lustron, and the imaginative systems of other influential figures, including Thomas Edison and R. Buckminster Fuller.

This contextual component of the exhibition will provide the foundation for a handful of full-scale commissions to be built in MoMA's vacant west lot....The fabrication and delivery of these projects will be documented in a special online exhibition, which will underline prefabrication's importance as a matter of process over product. Furthermore, the delivery and assembly of these projects will function as a real-time urban event that will be visible to the general public from the city streets

A Prefab Project says:

Perhaps notable for the absence of any of the commercially successful prefab architects working in the US, still kind of a big deal...

Haute Nature also commented.

Howstuffworks features a comprehensive article on prefab homes:

But what exactly is a prefab house? How are the pieces constructed and assembled? How much money does it take to get a house on a plot of land? And what kind of instructional manual comes with the ultimate model kit?In this article, we'll find out what prefabricated houses are all about.

The article is chock-full of information, with subsections including:

• Introduction to How Prefab Houses Work

• History of Prefab Houses

• Modern Prefab Houses

• Types of Prefab Houses

• Prefab Housing Cost

• Prefab House Construction

• Prefab Around the Globe

• Lots More Information

More details about the modular homes that are replacing FEMA trailers for Katrina victims:

People will have to apply for the housing and will pay rent in the first year of 20 percent of household income. After that, occupants have the option to buy the homes, and a portion of the rent can be used for a down payment. In addition, the occupants will get help finding mortgages.

Toll roads aren't just annoying to commuters; they can raise the cost of doing business:

A Pennsylvania law to toll Interstate 80...will have a devastating effect on Pennsylvania's modular housing industry, states The Modular Building Systems Association....Pennsylvania is the top producer of modular homes in the Northeastern United States and one of the top three (3) production states within the entire country. Approximately forty (40) percent of all homes produced in Pennsylvania are transported to other states and even if appropriately sized booths are placed at tolling areas, the toll fees and other related costs will add thousands of dollars to every home.

According to Don Shiner, President of DeLuxe Building Systems in Berwick, PA:

"The cost of our homes will increase not only because of the tolls imposed when we transport the finished home to the job site, but also on raw materials being delivered to our factories, employees traveling on company business, the return of empty undercarriages to the factories for reuse in transporting the next home, time delays in transporting our homes that will result from I-80 being a toll road and other, additional factors."

Link: Modular Building Systems Association

From The Southern Illinoisan:

Charlie and Ellen Sharpe have seen their business, New Horizons Homes, undergo much change in recent years...."This new modular home is a nice example of our construction."

Sharpe said the 2,300-square-foot structure features six modules, which were built independently off site in Pinckneyville.

"There's no worry about the weather," he said. "Materials are kept dry and there's less chance of theft. It's basically a safer work environment and much more efficient...."

Ellen said structures vary from one to three stories in height. Basically, no size is too small or large.

"It's just an educational process for the general public," she said. "This is the wave of the future. Instead of waiting months to build a house, it can be done in a matter of days. Our sales are up 15 percent from last year and we project a 40 percent jump next year."

Read the full article for details.

A few weeks back we reported on 40 lucky families moving from their FEMA trailers to new modular homes. The homes are done and families are moving in, according to the Press Register:

A group of community leaders stood in a circle, hands clasped, praying in the shadow of Bonnie and George Sprinkle's new elevated modular home.The Sprinkles are one of 40 families chosen to receive modular homes funded by a...U.S. Department of Housing and Urban Development grant to the city of Bayou La Batre. Seven families have moved into their houses so far....

The Mitchell Co. of Mobile has overseen the installation of the modular homes, which range between 1,100 and 1,400 square feet and cost between $100,000 and $115,000 each, depending on the elevation required.

The Virginia Gazette reports:

Ginger Crapse has the answer to affordable housing. “Build modular,” she said....“The perception is that they are glorified trailers,” she continued. “The inspector freaked out. I had to prove it’s modular. He said, ‘It can’t be. It doesn’t look like a modular house.’ People think modulars have to be perfectly rectangular. They see the porch and think that it can’t be modular....”

The ongoing affordable housing debate drives her nuts. “Every time I read this in the paper, I go epileptic,” she said. “They whine, ‘There’s no way to build a house for $110,000.’ There’s no reason we can’t get young families in affordable housing in Williamsburg. We are going to have problems getting teachers, firefighters, police and county employees.... “You can build and at a reasonable price.”

Michelle Kaufmann's  mkLoft will be used in a new development in Denver. From the Rocky Mountain News:

mkLoft will be used in a new development in Denver. From the Rocky Mountain News:

Denver developers Susan Powers and Chuck Perry are teaming with Kaufmann to put 40 factory-built town houses on 21 acres near Regis University at West 52nd Avenue and Federal Boulevard. The 1,100- to 1,500-square-foot town houses will be built at the All American Homes factory in Milliken, in Weld County, and trucked 60 miles, in sections, to the Denver site for assembly.That they're modular won't be apparent, as factory-built houses don't necessarily have the mass- produced, cookie-cutter look they did 30 years ago.

Read more about the plans in the full article.

From the Pensacola News Journal:

Dan Gilmore, a Pensacola developer...has teamed up with Mississippi modular home builder Buddy Jenkins to develop a market for affordable homes in the $150,000 range and below.Jenkins said Safeway Homes are not only affordable, but built to strict storm codes, and can withstand winds of 150 mph....

"We go several steps further, and have 14 stations within our factory where we check for quality control. Every piece of wood in our homes is glued and fastened with screws. We not only offer an affordable home, but a safe home."

Read the full article for details.

Office of Mobile Design's

Office of Mobile Design's  Swellhouse appeared last week in the LA Times:

Swellhouse appeared last week in the LA Times: