We covered several prefab and modular home conferences last year:

-

Hive Modular homes in Minneapolis and nearby St. Paul

Hive Modular homes in Minneapolis and nearby St. Paul

- a LV Series home you can rent in the Napa Valley

- a Frank Lloyd Wright prefab in Pennsylvania

- a weeHouse in Minneapolis

And museum exhibitions about prefab, our favorite being the opportunity to walk through Jean Prouve's Maison Tropicale.

A few of our favorite blogs posted round-up posts at the end of last year. Materialicio.us listed their top 25 stories of 2007, including a number of great prefabs. Jetson Green covered his most popular articles.

We were inspired to review our posts, clean-up the tags and share some highlights -- even if a bit late. First up, our favorite prefab news articles from last year.

From major US newspapers:

The New York Times wrote about prefabs as second homes.

The New York Post wrote about modular homes.

The Los Angeles Times discussed

OMD and the

OMD and the  Swellhouse.

Swellhouse.

The

Loblolly House appeared in the Washington Post and the Philadelphia Inquirer.

Loblolly House appeared in the Washington Post and the Philadelphia Inquirer.

Local papers:

We followed the replacement of FEMA trailers with modular homes.

Looked at modular homes in Long Island.

Covered modular homes in Mississippi.

And saw that modulars can be any size.

And more:

August brought Witold Rybczynski's Prefab Fad article. We disagreed.

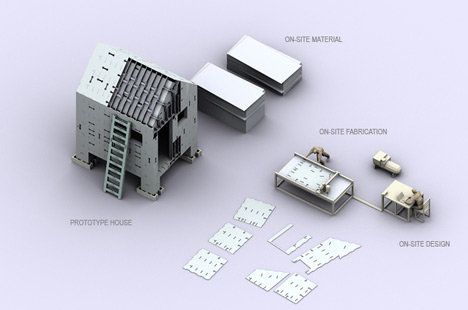

In October, we got excited about bringing the factory to the site and a pretty cool prefab penthouse.

Core 77 reports:

Before pre-fab became so fabulously fab, the Small Homes Council at the University of Illinois in Urbana, Illinois published Homes From Pre-Assembled Wall Panels in 1954.

A bit more about the Small Homes Council, now known as the Building Research Council:

For over 50 years, BRC (formerly known as the Small Homes Council) has conducted housing research and provided public service to residents, homeowners, builders, contractors, engineers, architects, and others in the housing industry. Today BRC continues to draw on the expertise of its own staff and a campus-wide network of experts to improve the state of our built environment.Current research projects include studies on building performance, moisture control, toxicity issues in residential building materials, windstorm resistance, diversity issues in the architectural profession, and housing environments design and evaluation.

We could not locate the book on AbeBooks.

Still employing similar techniques:

•  LV Series

LV Series

•  Modern Shed

Modern Shed

Blogs couldn't get enough of  The Magic Box, first seen on Moco Loco. Treehugger said:

The Magic Box, first seen on Moco Loco. Treehugger said:

Don't know what it costs, don't know what it's made of ... I will just say it is very pretty.

Jetson Green jumped in:

So I ask, after looking at the photos, does this Magic Box represent what's to come in the future? The Magic Box is cubic and versatile and small. It can go anywhere and be used as anything.

Not sure where The Good Human's Prefab Wednesday went, but they've been off since Jan. 3.

Inhabitat's Prefab Friday discussed a strange "prefab":

Winter shelter in the Arctic can take form in an upside down hunting boat – a traditional Inuit practice. Covey Island Boatworks, award winning builders of hand-crafted yachts, power and sailboats, has brought that idea into dry dock developing a prototype wood and epoxy prefab that applies boatbuilding principles directly to an extreme Arctic home.

Jetson Green showed off the flexibility of shipping containers:

It's hard not to gawk at the images of this building.

Jean Prouvé's  Maison Tropicale, which we talked about last year, will be on display in London:

Maison Tropicale, which we talked about last year, will be on display in London:

From the steamy jungle of Brazzaville in the Republic of Congo to the January drizzle of London's South Bank comes a tropical villa for the people. This weekend sees the construction of an unlikely addition to the capital's skyline: a prototype Modernist house designed in the Fifties by French architect Jean Prouvé.The historic colonial building, a kind of flatpack pioneer, has been brought to Britain for the first time by the Design Museum in partnership with Tate Modern. Today the gallery is halfway through reassembling La Maison Tropicale.... The Tate hopes the new house will be visited by as many as two million people.

From a recent  MetroShed press release:

MetroShed press release:

MetroShed ... has launched a brand new livable 12 foot deep by 16 foot wide MetroCabin for sale in the U.S....adding square footage to ... existing property has become a realistic alternative to many more people looking to expand space for an art studio, home office, exercise room, yoga room or guest suite.

The 12x16 MetroCabin features curved steel roof beams (with available straight roof package), Duro-Last Roofing, Batt Insulated Pre-Fab SIP walls, Birch Interior Panels, Meta Floor System and Premium heavy duty slide and glide doors.

The new  12' x 16' MetroCabin joins the original

12' x 16' MetroCabin joins the original  16' x 20' MetroCabin in the MetroShed product lineup.

16' x 20' MetroCabin in the MetroShed product lineup.

Jetson Green wants one:

Matter of fact, I've said it before, but I'd love to have one of these in the back to blog and exercise in.

I wrote about  Oskar Leo Kaufmann and Albert Rüf's

Oskar Leo Kaufmann and Albert Rüf's  System3 last week. It will be included in The Museum of Modern Art's Home Delivery exhibition.

System3 last week. It will be included in The Museum of Modern Art's Home Delivery exhibition.

The two designers have been working in the prefab arena since 1996. Past models include:

•  System 01 and

System 01 and  System 02 based on "elements"

System 02 based on "elements"

•  Su-Si,

Su-Si,  Fred,

Fred,  Houses A&B based on "units"

Houses A&B based on "units"

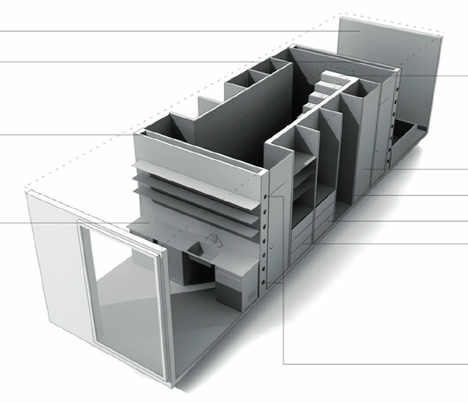

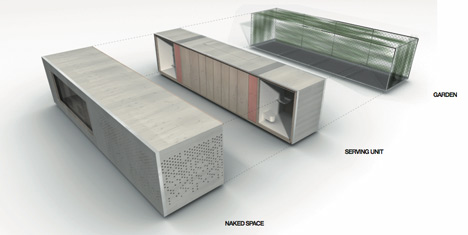

The System3 home merges the idea of "units" with that of "elements":

Due to the separation into serving units and "naked elements", the building process is optimized.

The serving unit is a completely prefabricated box including all installations. All different trades, such as electrician, plumber, etc. do their work at the service unit factory and do not have to do any on-site work....

The solid elements such as wall, floor, and ceiling are made of solid slabs of wood. The producer uses CNC-technology to cut out all openings.

...the window producer prefabricates all windows.

...the skin producer prefabricates the building's skin that includes thermal insulation, waterproofing and vapor barrier.

To me, it seems logical: keep the production of the technical pieces, the "serving units", in the factory where quality control can be tighter; let on-site work be limited to assembly and nothing more. This approach would save both time and money, limiting the trades and expertise needed at the home site; it reminds me of  KieranTimberlake's

KieranTimberlake's  Loblolly House, which we covered last June:

Loblolly House, which we covered last June:

The assembly process begins with off-site fabricated floor and ceiling panels, termed 'smart cartridges.' They distribute radiant heating, hot and cold water, waste water, ventilation, and electricity through the house. Fully integrated bathroom and mechanical room modules are lifted into position. Exterior wall panels containing structure, insulation, windows, interior finishes and the exterior wood rain screen complete the cladding.(KieranTimberlake's Cellophane House will also appear in the MoMA show.)

Such a mixed-method approach compares to the two major types of prefabrication that we cover on Prefabcosm: SIPs (used by companies like  CleverHomes and

CleverHomes and  Jensys Buildings) and complete modules (like those from

Jensys Buildings) and complete modules (like those from  OMD and

OMD and  weeHouse). Using just SIPs leaves the majority of the skilled work for the site, e.g. installation of utilities. Complete modules are both expensive and difficult to get to the home site. Merging the two methods allows for greater flexibility, less cost, higher quality, and shortened construction time.

weeHouse). Using just SIPs leaves the majority of the skilled work for the site, e.g. installation of utilities. Complete modules are both expensive and difficult to get to the home site. Merging the two methods allows for greater flexibility, less cost, higher quality, and shortened construction time.

With 10+ years working on prefab, Oskar Leo Kaufmann and Albert Rüf are worth watching. While they have yet to translate their experiments into a mass-market product, their work lends much understanding to how the home-construction industry might best take advantage of prefabrication.

Venturo, a fiberglass prefab from the 1970's has been talked about quite a bit around the blogosphere the past couple weeks. Treehugger says:

Venturo, a fiberglass prefab from the 1970's has been talked about quite a bit around the blogosphere the past couple weeks. Treehugger says:

There is really nothing new about many of the modern prefabs that everyone is going gaga over; back in the 70's Finnish architect Matti Suuronen designed the Venturo, a bit less extreme than his wonderful Futuro House. It appears to have been used primarily as gas stations for BP.

More from Finnish blog Tuovinen:

The "Venturo" is a modular, easily transportable building system, having excellent insulation, low weight and designed for minimum assembly on site.It is built of high quality materials in order to ensure maximum weathering properties for use in arctic as well as tropical climates and is almost maintenance free.

Being of low weight and factory preassembled, the Venturo means very low erections and foundation costs, where heavy equipment can be avoided.

Nineteen Venturos were built:

First prototype of this model was designed January 9, 1971 and first production unit was built June 1, 1971. According to Museum of Finnish Architecture, BP was built in 1971. BP-Högmo is the second Venturo built according to MFA....

The Venturo was released by Finnish company  Oy Polykem Ab following the success of Suuronen's earlier

Oy Polykem Ab following the success of Suuronen's earlier  Futuro House. From a paper titled Futuro's Way by Marko Home and Mike Taanila:

Futuro House. From a paper titled Futuro's Way by Marko Home and Mike Taanila:

Capitalising on the Futuro´s international exposure, Polykem Ltd. soon launched a whole series of plastic buildings designed by Suuronen. The Casa Finlandia series included the CF-100/200 service station (1969), the CF-10 kiosk (1970) and the CF-45 residential/commercial building, better known as the Venturo (1971). All the buildings in the Casa Finlandia series were designed to be durable and convenient to mass-produce, transport and assemble. The numerical suffix in each building´s name indicates its floor area in square metres. Polykem strove to sharpen the international profile of the Casa Finlandia series by publishing stylish 4-colour brochures complete with vivid product descriptions and catchy slogans.

More on the Futuro House from enthusiast Marc Berting:

Matti Suuronen designed this UFO shaped dwelling in 1968, initially for use as a ski-cabin or holiday home....The Futuro house was completely furnished and could accommodate 8 people. It was constructed entirely out of reinforced plastic, a new, light and inexpensive material back then. The plan was to mass-produce it, so it would be cheap enough to house all people around the earth. Because it was so light-weight, it was easily transportable by helicopter. Mobile living was the new possibility for the future. People could now take their moveable home with them, to wherever they went, and live like modern nomads.

Unfortunately the 1973 oil crisis spoiled all these plans. Prices of plastic raised production costs too high to be profitable. Only 96 Futuro houses were ever built. Besides the 48 made in Finland, also at least 48 were manufactured abroad on license.

We recently added Modular Today to our sidebar. The site is useful for anyone looking to build a modular home, with information ranging from an expected timeline to a financing guide.

The Good Human's Prefab Wednesday took the week off.

Inhabitat's Prefab Friday looked at a Swiss prefab that uses straw bales:

We’re quite taken by Strohhaus in Eschenz, Switzerland. Designed by Zurich-based architect Felix Jerusalem, this home masterfully combines prefab with sustainable materials, primarily prefabricated strawboard panels that provide affordable, environmentally sound insulation.

Jetson Green covered GreenMobile, an "ultra-affordable, modular green [manufactured] home":

GreenMobile was awarded $5.8 M from FEMA to further develop the prototype and roughly 80 units are in the pipeline right after that prototype comes through.GreenMobile is expected to cost about $50k

100khouse likes the 'Option' House, covered on Prefab Friday a couple weeks back.

The Michelle Kaufmann blog announces:

...we have been working very hard for the past few months to get to this point and are now finally ready and delighted to announce that MKD is going to be a part of the “Smart Home: Green + Wired, Powered by ComEd and Warmed by Peoples Gas” exhibit at MSI that’s opening this spring! The exhibit is going to include a full-size mkSolaire™ home to be built in on parkland on the southeast side of the Museum and will showcase the very best in sustainable living concepts and solutions.

A bit more from the museum exhibit page:

During its 75th Anniversary year, the Museum of Science and Industry will be building a functioning, three-story modular and sustainable “green” home ... to highlight unique home technologies for the 21st century.

The Greater Fort Wayne [Illinois] Business Weekly quotes Art Breitenstein of the home's builder, All American Homes:

The home’s module construction will be under way for two or three more weeks on one of the All American assembly lines in Decatur....“This is a special house, a very high-priced house; it has the best of the best. ... there’s a lot of new technology in there that’s one-of-a-kind that if it becomes accepted by consumers, like anything else, the price comes down of course.”

Jetson Green says:

I can't wait to see more!

System3, from Austrian designers

System3, from Austrian designers  Oskar Leo Kaufmann and Albert Rüf, will also be showcased in MoMA's Home Delivery: Fabricating the Modern Dwellings show:

Oskar Leo Kaufmann and Albert Rüf, will also be showcased in MoMA's Home Delivery: Fabricating the Modern Dwellings show:

The system is based on the separation of a building into "serving space" and "naked space".The "serving space" is a completely prefabricated serving unit that provides all staircases, kitchens, baths, installations, electricity, heating, and cooling systems for the entire building. The "naked space" (space that is only defined by the placed furniture, such as living or sleeping rooms) is formed by "naked elements": solid slabs of wood...windows, skin. All "naked" elements are also prefabricated and are delivered directly from factory to building site, where everything can be assembled in a few days.

Each unit fits in a shipping container, giving it the characteristic "long and narrow" format. Several units can be placed side by side:

Or stacked:

Overall, an intriguing approach that I can't wait to see realized at MoMA. Oskar Leo Kaufmann and Albert Rüf have been experimenting with prefab since 1996. We'll look at their past work in more depth soon!

I wandered over to the  XtremeHomes site the other day and found that they are now writing a blog:

XtremeHomes site the other day and found that they are now writing a blog:

A brief collection of thoughts on the growth of the green building industry. What's real, what's not and what people are expecting.

Definitely worth keeping an eye on.

From the Dwell blog:

The Consumer Electronics Show may have the flashiest booths of any trade gathering in the world. .... So imagine my relief when I saw a modest prefab home built at the far end of one of the main halls. .... It was built inside the convention center for Olevia, a company that makes energy efficient televisions.

The Aegean is a container home from  Logical Homes, the Packaged Architecture™ brand of Los Angeles architect Peter DeMaria.

Logical Homes, the Packaged Architecture™ brand of Los Angeles architect Peter DeMaria.

MocoLoco provided more details:

...the exhibit at CES represents the first built prototype.and quotes an email from Michael Sylvester of Fabprefab fame:

The house has modern lines and a long cantilevered roof - you can hardly see that this home is based on the adaptive re-use of two forty foot cargo containers.

Inhabitat liked the prototype:

...the stunning shipping container prefab definitely caught our eye.

The line of homes is based on the architect's Redondo Beach House:

The traditional design, permit and construction process, compounded by skyrocketing construction costs, has necessitated a re-birth of the design/build approach to creating Architecture.... This project is a Recycled Steel Shipping Container based building that also employs a combination of conventional stick frame construction and prefabricated assemblies. These materials result in an end product that is affordable and nearly indestructable. The modified containers are mold proof, fire proof, termite proof, structurally superior to wood framing and along with various other “components” come together to create a system/kit of parts that is predicated on cost savings, construction timesavings, and energy/environmentally conscious priorities....

CNN covered the Redondo Beach Home in 2006:

(Hat tip: Treehugger commented.)

Systm, a web video series from Revision3, files a long, detailed video report from the WIRED LivingHome:

This $4 million home in LA isn't exactly what we think of when wanting to integrate more green, eco-friendly aspects to our lives, but it does offer up some great options. LEED certified and designed by architect Ray Kappe, this home offers a great, simple way of constructing a house without compromising the uniqueness of a custom built home.

Check out the multimedia page on the WIRED LivingHome site for additional photos and videos.

WIRED published an annotated slideshow of small prefabs last week:

The world is getting hotter and more crowded every day, and modular, prefab housing is just what the doctor ordered. When you go small, it's not just about energy efficiency and carbon footprints -- it's also about being strange, cool and beautiful. We've chosen our favorite houses that meld style with globally conscious living. Enjoy.

Models included:

•  weeHouse

weeHouse

•  Modern Cabana

Modern Cabana

•  Marmol Radziner Prefab

Marmol Radziner Prefab

•  micro compact home

micro compact home

Treehugger summarized:

Some are real and some are vaporware; all have been around the block a few times. And of course, the comments include "why are these so expensive?"

Curbed LA watched an  OMD home being delivered:

OMD home being delivered:

These shots, taken last month, show the delivery of a two-story prefabricated home going up in the Ocean Park neighborhood of Santa Monica. The 2,200 square foot home is comprised of 4 modular units; these shots show the upper two being installed.

Treehugger reports:

We previously showed the Travelpod, an experimental prefab from Travelodge, and thought it was an interesting one-off. We were wrong; the company is looking seriously at prefab hotels and is building their first in the west London district of Uxbridge, right now.

The Good Human's Prefab Wednesday was off this week.

Inhabitat's Prefab Friday made a surprising architectural discovery at the the Consumer Electronics Show. We'll cover that model soon.

architecture.MNP discussed a recently completed  Resolution: 4 project.

Resolution: 4 project.

A number of folks had thoughts on the Home Delivery prefab exhibition at MoMA. The Dream Antilles had a good idea:

If these houses are supposed to be good, somebody should live in them during the show and the people who view the exhibit should be visitors in the houses.

Jaunted provided some new details:

Foundations will be laid in February and the homes will arrive in late May, popping up in next to no time.

The Chicago Tribune predicts:

Given MoMA's taste-making power and its location in the media capital of the world, the show could go a long way toward making prefab housing something more than just a glimmer in visionaries' eyes.

greenbuildingsNYC is excited. The Gothamist commented, as did Curbed. Treehugger mentioned the show. The Chronicle of Higher Education likes the idea that professors' work will be included in the show.

We've added status designators to each model and variation page. The  BURST* page is shown above, with status "prototype." Each model is designated as either:

BURST* page is shown above, with status "prototype." Each model is designated as either:

available: can be purchased now (example:  micro compact home)

micro compact home)

prototype: includes concepts, demonstration homes, and models that will be available in the future (example:  Aperture House)

Aperture House)

discontinued: ... but worth tracking to see how the industry changes over time (example:  v2shell)

v2shell)

Update: The model appearing in the MoMA show will be the BURST*008.

SYSTEMarchitects'

SYSTEMarchitects'  BURST*003 house is the third prefab model featured in the MoMA prefab exhibition.

BURST*003 house is the third prefab model featured in the MoMA prefab exhibition.

Artdaily provides some details:

Designed to be assembled on site from laser-cut pieces, the Burst *003 house is a computer-designed remake of the typical prefabricated box. Working from a computer formula that automates the specific pieces needed to create the house desired, the project is based on a system that can be adapted to a changing set of criteria. The 2003 prototype of the Burst *003 project was built on Australia's Northeast coast, and won the Royal Australian Institute of Architects 2006 Wilkinson award.

Architecture Australia explains further:

Laying out the plywood pieces was achieved using the software program used in garment manufacture with very little wastage. While high technology is used throughout the design and manufacturing process, low technology is intentionally employed for assembly and for maintenance. Assembly requires fewer skills but intense cooperation and concentration. The building was put together by architecture students in something akin to a barn raising. The architects are fond of this image, yet recognize that the design’s reliance on numbers of enthusiastic and sympathetic cheap labourers will make it less desirable for some.

This fabrication method reminds me of the yourHouse. The process is explained through images and text on the SYSTEMarchitects site:

Plywood cut by a computer-controlled laser. Delivered to site in sheets with the ribs numbered, scored, and holes cut.

Laser cutting 1 of 400 sheets.

Sorting 1,100 pieces of laser-cut plywood.

Underside of floor structure.

Laser-cutting efficiency -- the total waste from the plywood sheets.

I can't help but be excited for the potential of the BURST* system and look forward to seeing the home at MoMA.

The  m-ch (micro compact home) will also be included in the upcoming MoMA prefab exhibition.

m-ch (micro compact home) will also be included in the upcoming MoMA prefab exhibition.

The New York Times says:

Mr. Horden’s Micro Compact House — Mr. Bergdoll [of MoMA] described it as “a giant livable Sony radio cube” — is topped with photovoltaic panels and has wind turbines in its walls, allowing the house to generate its own electricity. An aluminum-clad perfect cube, with about 76 square feet of living space, the tiny dwelling is intended for use as athletic or student housing, or as a miniature vacation house. Mr. Bergdoll met with Mr. Horden in one of his cubes, a space so compact that the architect managed to make espresso on the kitchen counter without leaving his seat at the dining table.The house is commercially available — it recently went on the market in Europe — and can be delivered by helicopter or crane.

From the micro compact home site:

The micro compact home [m-ch] is a lightweight compact dwelling for one or two people. Its compact dimensions of 2.6m [8.5 ft] cube adapt it to a variety of sites and circumstances, and its functioning spaces of sleeping, working / dining, cooking and hygiene make it suitable for everyday use.Informed by aviation and automotive design and manufactured at the micro compact home production centre in Austria, the m-ch can be delivered throughout Europe with project individual graphics and interior finishes.

The team of researchers and designers based in London and at the Technical University in Munich developed the m-ch as an answer to an increasing demand for short stay living for students, business people, sports and leisure use and for weekenders. The m-ch, now in use and available throughout Europe, combines techniques for high quality compact 'living' spaces deployed in aircraft, yachts, cars, and micro apartments. Its design has been informed by the classic scale and order of a Japanese tea-house, combined with advanced concepts and technologies. Living in an m-ch means focusing on the essential - less is more. The use of progressive materials complements the sleek design. Quality of design, touch and use are the key objectives for the micro compact home team....for 'short stay smart living'.

The specifics:

The m-ch has a timber frame structure with anodised aluminium external cladding, insulated with polyurethane and fitted with aluminium frame double glazed windows and front door with security double lock; graphics can be applied for sponsors, exhibition and business use.

- two compact double beds...

- storage space for bedding and cleaning equipment

- a sliding table ... for dining for up to five people

- flat screen television in the living/dining space

- a shower and toilet cubicle

- a kitchen area, which is fitted with electrical points and features a double hob, sink and extending tap, microwave, fridge and freezer units, three compartment waste unit, storage shelves, cutlery drawers with gentle return sprung slides and double level work surfaces

- thermostat controlled ducted warm air heating, air conditioning, water heating

- fire alarm and smoke detectors

m-ch units are available to purchase for delivery to geographical Europe at a guide price of EUR 25,000 to EUR 34,000 (subject to contract).

More images of the interior:

We've mentioned the home before in our This Week series. Back in June, we also linked to a video of the m-ch.

Yesterday we reported on the Home Delivery: Fabricating the Modern Dwelling exhibition at MoMA. In the coming days, we will preview each of the companies and homes featured in the exhibition.

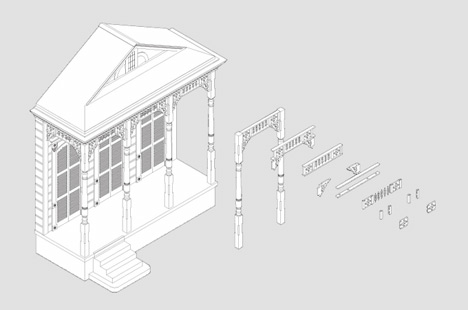

First, let's take a look at yourHouse, from Lawrence Sass at MIT:

This design of yourHOUSE is a reinterpretation of historical New Orleans style “Shotgun” Housing utilizing recycled plywood as the main structural material. The house will be fabricated and assembled entirely of friction-fit components, completely eliminating the need for mechanical fasteners such as nails and screws. This fabrication technique is made possible through the extensive use of computer numerical control (CNC) milling machines....The goal of the yourHOUSE project is to exemplify a design process which utilizes cutting-edge technologies rooted in long term research efforts with the intent to illustrate a system that allows prefabricated housing to be low-cost and yet high-quality.

The processes include:

Digitalization

Digitalization is a 2-stage process which preceeds a materialziation process. First, 2-dimensional data was taken from the documentation and used to create elevation drawings. From this data, 3-dimensional data was extrapolated and digitally modeled so that the house facades could be transformed into solid physical models through a final materialization process.

Materialization

Materialization begins by breaking down the digital model into a logic of component parts and assemblies. In the figure above is one such breakdown of a front porch column assembly

The final stage in the materialization process involves what is termed, 3D printing. This stage allows the researcher to examine the digital model as a solid physical body. In the figure above are 1:30 scale 3D prints of the four originally documented New Orleans 'Shotgun' house facades

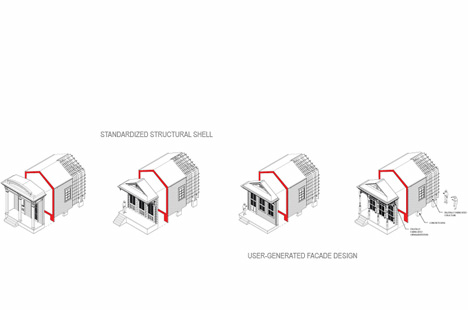

The yourHouse concept also embraces customization:

One of the core strategies driving project yourHOUSE is the use of mass-customized as well as mass-standardized components. This strategy happens at multiple scales ranging from details to major structural features. As seen in the figure above, the main body of the house employs a standardized structural shell while the front porch of the house can be customized to suit the inhabitant's desires.

It will be exciting to see this concept realized for the MoMA show.

The New York Times reports:

...the Museum of Modern Art has commissioned five architects to erect their own prefab dwellings in a vacant lot on West 53rd Street, adjacent to the museum. Whittled down from a pool of about 400, the five architects are participating in “Home Delivery: Fabricating the Modern Dwelling,” an exhibition opening in July.The five, to be announced today by the museum, are KieranTimberlake Associates of Philadelphia; Lawrence Sass of Cambridge, Mass.; Douglas Gauthier and Jeremy Edmiston of Manhattan; Oskar Leo Kaufmann and Albert Rüf of Austria; and Richard Horden of Horden Cherry Lee in London.

The MoMa site fills in some blanks:

This exhibition will offer the most thorough examination of both the historical and contemporary significance of factory-produced architectures to date. With increasing concern about issues such as sustainability and the swelling global population, prefabrication has again taken center stage as a prime solution to a host of pressing needs. The prefabricated structure has long served as a central precept in the history of modern architecture, and it continues to spur innovative manufacturing and imaginative design....The exhibition will examine this phenomenon through historical documents, full-scale reassemblies, and films that trace the roots of prefabrication in the work of architects including Frank Lloyd Wright, Jean Prouvé, and Richard Rogers, corporations such as Lustron, and the imaginative systems of other influential figures, including Thomas Edison and R. Buckminster Fuller.

This contextual component of the exhibition will provide the foundation for a handful of full-scale commissions to be built in MoMA's vacant west lot....The fabrication and delivery of these projects will be documented in a special online exhibition, which will underline prefabrication's importance as a matter of process over product. Furthermore, the delivery and assembly of these projects will function as a real-time urban event that will be visible to the general public from the city streets

A Prefab Project says:

Perhaps notable for the absence of any of the commercially successful prefab architects working in the US, still kind of a big deal...

Haute Nature also commented.

G Living commented on the TrailerWrap project:

While the low cost motive behind the introduction of mobile homes in the mid-1900s was a good one, the execution was often aesthetically reprehensible, shoddily constructed and inefficient energy-wise. TrailerWrap set out to take these small, dilapidated (often abandoned) structures and re-fashion them into something exciting and remarkable, yet sustainable and affordable.

Freshome covered the  Perrinepod:

Perrinepod:

a cute prefab home that can be built in just 3 days and withstand everything from earthquakes to cyclones.

The Good Human's Prefab Wednesday showed a prefab development in London that was covered last year on some of the other blogs.

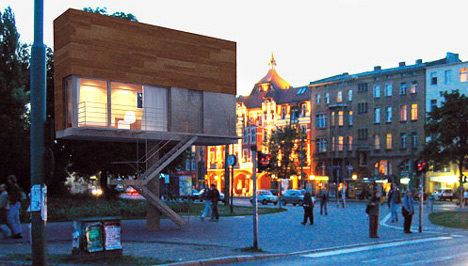

Inhabitat's Prefab Friday featured the Single Hauz, a sort of house-meets-billboard:

...the idea takes shape in such a stylish little form that we can’t help ponder the challenge posed: how much space do you really need and where do you want it?

TreeHugger posted a video of  Adam Kalkin speaking about containers, and looked back at their enthusiasm of three years ago.

Adam Kalkin speaking about containers, and looked back at their enthusiasm of three years ago.

From the  miniHome site:

miniHome site:

In order to provide more living space in the miniHome SOLO, we have been asked by many of you to allow for additions. The best way to do this was to work with the exisiting floor levels and roof lines of the SOLO, and find a way to ‘marry’ the two pieces to give the best interior spaces.

The result: the  miniHome DUO SE:

miniHome DUO SE:

The miniHome DUO is a modified miniHome SOLO with more! Two units ship separately to your site, and then combine at the ‘marriage wall’ - a simple operation that makes the DUO a permanent home1. Both units are classed as trailers (CSA Z220- RV), are on wheels and a steel chassis and both feature detachable hitches. The units can be towed to any site and requires no foundation or infrastructure hook-ups. Designed and built in Canada for year round living, the DUO’s robust construction is super-insulated, making it quick and easy to heat and cool. The DUO also features an optional woodstove, for colder climates.

For the environmentally minded:

The DUO has numerous environmental advantages over conventional housing. A smaller building uses less resources and energy to build, and ultimately much less energy to operate and maintain. The modular design also keeps construction waste, shipping costs and energy to a minimum.

Jetson Green wants one:

Really, anything is possible with this little treasure home. Small. Stylish. Green. Affordable.

On the heels of the port-a-bach comes news of the iPad, another prefab "bach" (see note below) from New Zealand:

The iPAD is a true kitset bach designed to covers a range of options; it could be a one bedroom holiday home, secondary dwelling, granny flat, office, studio or resort unit to name but a few.It can be grouped as a series of pavilions to form larger accommodation if required....

Of particular note is that the iPAD can be either manufactured off-site and easily transported to its final destination, or shipped as a kitset and erected on site by a licensed contractor.

TreeHugger has some thoughts and also mentions the earlier Bachkit.

Bach = "small structures like beach huts or small holiday homes" (from Shedworking)

(Hat tip: Materialicio.us)

Here's a unique hybrid wall panel, sort of half SIP, half straw bale:

The Enviro Board panels offer a superior building product that is easy to handle and assemble. Today's Enviro Board Panels are solid "concrete like" fiber panels comprised of highly compressed straw fibers. Through the Enviro Board technology, panels are extruded through the mill in a continual process, covered with a durable waterproof paper membrane, cut to desired lengths and end-capped. Panel density and thickness can also be adjusted.The Enviro Board panel replaces conventional and traditional building materials, such as drywall, thermal insulation, exterior moisture barrier (typically tar paper) and exterior plywood. In addition, because of its 32" width, using Enviro Board panels requires 50% less studs and eliminates unnecessary expenses in the form of materials and labor needed to assemble the materials.

From YouTube:

(Hat tip: Materialicio.us)