We recently came across an interesting project called The OPEN Prototype Initiative (OPI). It is:

... developing a series of prototypical homes to test a new model for the design, fabrication and assembly of highly responsive places of living.

Founding partners:

More information is available on the OPI website:

We look forward to seeing more from this collaboration.

materialicious moved from materialicio.us to materialicious.com. They've been reposting old content and adding some new content.

Jetson Green's guest post on affordable, green prefabs sparked a few responses around the web. Treehugger's Lloyd Alter concluded:

If Jim Kunstler is right and the American suburban experiment is dead, then there will be lots of cheap labor about and prefab is pretty much dead too- it will never be competitive.

But at some point when the housing market returns and there are banks that lend money, people are going to demand the quality and consistency that comes from a factory. That's why cars aren't built in driveways.

BuildingGreen also had something to say:

Unlike Ludeman, I'm not ready to give up on prefabrication just yet. I still think there's promise in the idea of prefabricated green, especially in the mainstream and affordable housing markets. As for green modernist housing, the benefits of prefabrication may never come through for such a relatively small market.

Inhabitat's Prefab Friday looked at the Cellophane House from  KieranTimberlake Associates:

KieranTimberlake Associates:

If its ease of construction doesn’t amaze you, consider the aluminum frame and structural polycarbonate floor plates. Or the easy bolt connections that facilitated the easy assembly and the available built-in environmentally-friendly features, and then you just might be wondering if you covet the ingenuity behind these homes.

Dwell reports:

...for those who can’t visit the city anytime soon, the museum now has an online version of the show, replete with installation videos, archival footage, and an interactive timeline of prefab housing.

Admittedly, clicking through Home Delivery can’t beat scaling the five structures that now stand in the museum’s adjacent lot. But it’s certainly the next best thing.

The online exhibition takes over the top portion of the blog. It's quite comprehensive; well worth a look.

We've been following A Prefab Project's construction of a  Resolution: 4 Architecture home since near the beginning.

Resolution: 4 Architecture home since near the beginning.

Over a year later, the home is complete and available to rent. It's an excellent opportunity to understand what a Resolution: 4 Architecture home can be. Homeowners Chris and Sarah have definitely put a lot of energy and care into the home, and it shows.

A few guests have been testing the place out over the past couple months. Chris shared some stories:

... all of the folks who have stayed so far have been superstars. John and Laura, our first guests, talked with me for an hour on the phone about their visit, and took copious notes. (And have already booked two more weekends!) Chris and Ritamary chipped in one of those wire brush scrubbers for the grill. Ross and Libby sent along a professional-quality blurb and a fancy corkscrew. And Jake, whose Herculean bicycle trip from Pittsburgh to our cabin really cannot be appreciated unless you are a biker.

Jake documented his bicycle trip to the cabin with a blog and great photos.

Our previous coverage of the project:

- the home was delivered and set about a year ago

- lessons learned in July of last year

- a budget update in August

I'm a little obsessed with the progress updates over at MoMa's Home Delivery blog. Not least: several of the videos are great -- but some of their best are hidden behind a proprietary interface.

Try this. In the top right corner of their blog, move your mouse over the image. With luck, a control bar will slide up a bit from the bottom. Click the tiny square icon on the right and notice that the hard-to-read gray text on a light gray background changes. In theory, that means you switched to another video. In practice, it's hard to tell since there's not much action in some of them.

The time-lapse installation videos are definitely worth a look -- though it would be much better if each video was in a separate post that bloggers could link to.

I've received an update on a few  EcoSteel projects. There's been significant progress with the house and observatory (pictured above), designed by

EcoSteel projects. There's been significant progress with the house and observatory (pictured above), designed by  Gregory La Vardera, that we first covered them about a year ago.

Gregory La Vardera, that we first covered them about a year ago.

The large project consists of a 7,000+ sf custom home, a "toy garage" and a private observatory. Definitely not your average home! Because of the project's remote location in Rodeo, New Mexico, not many contractors were available. So, homeowner Steve Cullen chose prefab. Some of the advantages:

- faster build

- ease of delivery and installation

- design flexibility

- strength and quality control

- eco-efficiency

A number of images of the home's progress, as well as some cool night shots of the observatory are available on Picasa.

Another project, Goshawk Ranch, has its own blog. Under construction since September, the home looks to be moving along. The blog's most recent post shows the newly installed wall panels and front door.

EcoSteel's prefab system consists of a home's steel frame, both interior and exterior, along with exterior wall and roof panels. The remainder of the design and materials are left to the homeowner and local contractors. We discussed the system in detail last year.

This skeleton-and-skin sort of offering is not uncommon. A number of other prefab companies sell similar systems, with a range of additional design help.  Rocio Romero's

Rocio Romero's  LV Series homes come without finishes, but with a list of recommendations on finishes and vendors. And

LV Series homes come without finishes, but with a list of recommendations on finishes and vendors. And  Sander Architects design the entire home, but only prefabricate the steel framing.

Sander Architects design the entire home, but only prefabricate the steel framing.

Alchemy Architects has had a blog for a while, but just recently, Alchemy's Betsy Gabler has been updating frequently with information on the

Alchemy Architects has had a blog for a while, but just recently, Alchemy's Betsy Gabler has been updating frequently with information on the  weeHouse.

weeHouse.

One post covered a not-so-weeHouse in PA:

Owners of the Johnson Creek weeHouse have graciously provided some great new pictures of their 4 box weeHouse in Pennsylvania.

The Alchemy Architects website provides a description of the home (seen above) and additional images:

This 2,200SF 3BR retreat home consists of a larger main unit accommodating most daily activities and a smaller sleeping tower. Both units are connected by an elevated patio bridge component.

A post from last week profiled a weeHouse in upstate New York:

- process started with Alchemy in October 2007; site work (client started from scratch which means even putting in their own septic and well systems) and preliminary design happened throughout the winter of 2007-2008

- house is due to be 'set' in Fall 2008

- floor plan follows the weeHouse side x side PAIR that has two bedrooms and one bath; client added screen porch (great idea!) using Alchemy's additional design services and also worked with their general contractor to customize a walk-in basement...

- total square footage (including exterior deck and porch) = 1250

- (06/08): price for weeHouse PAIR in NY is listed at $189K; this house with additional design options/fees is still coming in at under $200K (about $160/SF); additional costs include site work, basement, transportation, and set/hook-up fees (many of these are priced differently by region)

We're still waiting for the Build a wee page to become active. Hopefully we'll see that announced on the blog soon!

Also: there's a weeHouse page, updated frequently, on Facebook. You have to be a friend to see the profile, but you can find it through a search.

Modular builder  Empyrean International has launched a new website. We've previously covered their Acorn and Deck Houses and discussed their

Empyrean International has launched a new website. We've previously covered their Acorn and Deck Houses and discussed their  Dwell NextHouse at length.

Dwell NextHouse at length.

The new site features much improved navigation and more detailed information:

- a brief review of building systems

- an explanation of their collaborative process

- a rundown of current projects

- a schedule of upcoming events

- a map of Empyrean homes around the world

Speaking of Empyrean, the Silicon Valley NextHouse was open to visitors last week. Interior designer Sally Kuchar was there and shared stories and photos on her sallyTV blog.

Marmol Radziner have a launched a blog:

Marmol Radziner have a launched a blog:

We hope to post regularly on a range of topics, including the various projects that we currently have in design and production, events around the country, or just interesting articles and ideas that influence what we do.In the coming months, we’ll be blogging a lot about the Venice House (a.k.a. California House 6). This house is currently in our factory and will be delivered to a small, urban lot this spring. We designed [the] house to respond to the narrow, infill site by having the home look inwards towards small, private courtyard spaces. This allowed us to maintain an open, bright feeling that connects indoor and outdoor spaces despite the small lot.

A recent post discussed putting a concrete floor in a prefab house:

We loved how the concrete floors in the Desert House looked, but we shied away from using them in our first few projects that we produced in our own factory. The Desert House’s concrete were so beautiful, but also so heavy, which made the installation quite challenging...

We'll keep track of any big updates over at the new blog, but be sure to check it out for yourselves.

Santa Monica-based Minarc has a (minimal) new website for their M3house.

We first encountered Minarc last April. Treehugger covered them again in July:

We admired the Minarc house by Tryggvi Thorsteinsson and Erla Dögg Ingjaldsdóttir when it was in Dwell; now we learn that they are offering it in a prefab version. The designers...have wanted to design a high-tech modern home that only used materials "in their most organic form and that used recycled materials wherever possible."...They are offering three modular versions built from 2x6 walls, lots of insulation and radiant flooring.

land+living shared several images of a non-prefab prototype from a tour last year. The Minarc brochure (pdf) released at the time explained their  eBOX series 05. It looks like the M3house will be quite different.

eBOX series 05. It looks like the M3house will be quite different.

We look forward to more details on the new home. The image above is the only thing on the new site; what a tease!

We covered many informative websites on prefab and modular homes last year. A few of our favorite posts:

In May, we found the

LV Series Yahoo! Group, a great resource on

LV Series Yahoo! Group, a great resource on  Rocio Romero's

Rocio Romero's  LV Series homes

LV Series homes

We wrote about

Nashville Modern Prefab in June. The plan: to build a Hive Modular home. Sadly, it looks like

Nashville Modern Prefab in June. The plan: to build a Hive Modular home. Sadly, it looks like  work has stalled.

work has stalled.

Shedworking entered our radar at the end of June. The blog is a great source of information on small prefab homes.

Shedworking entered our radar at the end of June. The blog is a great source of information on small prefab homes.

We love

A Prefab Project, which tracks the progress of a

A Prefab Project, which tracks the progress of a  Resolution: 4 Architecture home in West Virginia. In July, we watched the home being delivered.

Resolution: 4 Architecture home in West Virginia. In July, we watched the home being delivered.

Also in July:

Hive Modular started a

Hive Modular started a  blog.

blog.

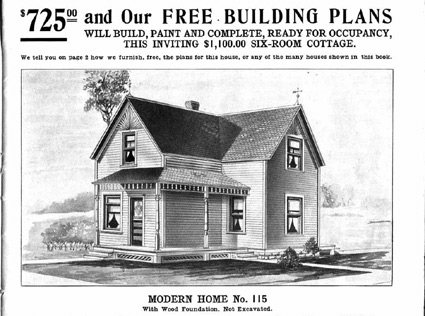

Sears Homes were some of the earliest prefabs. We were excited when we found a great resource on the homes: the

Sears Archives.

Sears Archives.

I'd forgotten about this one: we covered a great Flickr set of a

Flatpack House going up. Now the home is

Flatpack House going up. Now the home is  much more complete.

much more complete.

In December, we came across

ModularHomeChoice.com. It offers some useful information about building a modular home.

ModularHomeChoice.com. It offers some useful information about building a modular home.

And we saw

Secret Fortress Hideout, a blog all about the construction of an

Secret Fortress Hideout, a blog all about the construction of an  LVL Home.

LVL Home.

Greg LaVardera brings us Letters from Sweden - land of modern, land of prefab:

Greg LaVardera brings us Letters from Sweden - land of modern, land of prefab:

In my previous entry I introduced Scott, my correspondent from Sweden. An American builder relocated to a suburb of Stockholm, he landed in an alternate reality where modern housing was everywhere, commonplace, even dare I say unremarkable. None of the stigmas or resistance we have come to associate with building a modern house were present. Every builder offered solid modern design in the range of homes they sold, and were more than happy to sell you one. On top of this prefabrication techniques were the norm. Sizable portions of the houses Scott saw being built were put together in the factory...

What did Scott find?

"...the majority of new construction is built like this. I would call the house panelized - but it is "way way panelized" and is a total package. The houses come on trucks from rural places in Sweden. The windows are in, the insulation, wiring, wallboard where possible - every thing - the pipes, the wiring systems, the doors, stairs ... everything has been engineered and rationalized to reduce labor, find energy and material economy and work with the method of construction where stuff is pre-assembled as much as possible inside a building and then "erected" or installed on the site under very compressed schedules...."

Read the full post for Greg's comparison to prefab on this side of the pond.

We recently added Modular Today to our sidebar. The site is useful for anyone looking to build a modular home, with information ranging from an expected timeline to a financing guide.

I wandered over to the  XtremeHomes site the other day and found that they are now writing a blog:

XtremeHomes site the other day and found that they are now writing a blog:

A brief collection of thoughts on the growth of the green building industry. What's real, what's not and what people are expecting.

Definitely worth keeping an eye on.

Howstuffworks features a comprehensive article on prefab homes:

But what exactly is a prefab house? How are the pieces constructed and assembled? How much money does it take to get a house on a plot of land? And what kind of instructional manual comes with the ultimate model kit?In this article, we'll find out what prefabricated houses are all about.

The article is chock-full of information, with subsections including:

• Introduction to How Prefab Houses Work

• History of Prefab Houses

• Modern Prefab Houses

• Types of Prefab Houses

• Prefab Housing Cost

• Prefab House Construction

• Prefab Around the Globe

• Lots More Information

From the mailbox:

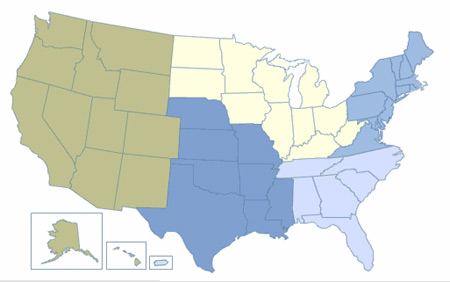

We like to think of weeHouses as being Good+Cheap+Fast, and, along those lines, we hope you'll find our new Web site Good+Helpful+Fast. After several months of painstaking discussion and analysis, followed by several more of crying, wailing, and gnashing of teeth, we feel like we've come up with a site that successfully conveys massive amounts of information, while showcasing our office's playful, creative nature. We really hope you like it! Visit us at www.weehouse.com to check out our new line of standard weeHouses, complete with plans, pricing, and superFancy interactive graphics, or to browse our top-notch custom architectural projects. There's lots of great new stuff to see, do, and learn.

The new site features 360 degree views of all of their prefab models and detailed pricing, based on the region of the country you live in. Coming soon: the ability to build and price your custom  weeHouse.

weeHouse.

Jetson Green is a fan:

I love it because you can see houses they've built, projects in planning....If you're looking to get a home, you want to go with a company that's actually built something.

Resolution: 4 Architecture's modernist prefab appears on video:

Resolution: 4 Architecture's modernist prefab appears on video:

On this edition of Floorplan, OpenHouse NYC host George Oliphant talks to a homeowner, a homebuilder and a home seller to get the definitive breakdown on how a modular home is built, designed, sold and used.

The video also includes a tour of a more traditional modular home.

(Hat tip: banks.com)

For any of you Sears Home enthusiasts:

If you think houses built from kits are shoddy, cheap and obvious, think again. Between 1908 and 1940, Sears sold about 70,000 homes in all 48 states through their mail-order Modern Homes program, with 370 designs that you might not readily recognize as a kit home. Sears kit homes were shipped via boxcar and came with a 75-page instruction book. Each kit contained 10,000 - 30,000 pieces and the framing members were marked to facilitate construction. Many decades later, those same markings can help identify a home as a Sears kit home. So if you're wondering if that adorable little bungalow with the big eaves (or even your own house) is a kit home, read on for signs that will help you identify if it is indeed a historically significant Sears kit home.

Read the full how-to at wikiHow.

While visiting the LV Home Fans Yahoo! group the other day, I happened upon a site I hadn't seen before, Secret Fortress Hideout:

This blog documents the progress of our super-cool, pre-fab home "somewhere" in the wilds of Northwest Arkansas. Rocio Romero designed the home, model LVL, and incorporated our custom modifications.

Recent posts have covered insulation, lighting design, and construction delays:

A few critical path items jumped the track and will push us back about a week.

The stainless kitchen cabinets we ordered from Lasertron will be delayed due to an email mixup.

The heat won't be connected for two weeks, which delays the floor installation.

We found out cultured marble won't work for the tub or bathroom sinks and devised a Plan B (Neptune Zen Soaker Tub and custom-fabricated under-mount stainless trough sinks).

And, last, but not least, the company Don scheduled to prime the drywall bumped us a week.

I guess these things happen in building. It's just wild that they all happened in the last two days.

Like A Prefab Project, Secret Fortress Hideout provides a great first-hand look at the construction of a prefab home.

I came across ModularHomeChoice.com while perusing some news the other day:

This website is for those interested in purchasing a modular home or those considering one and wishing to learn more about them. I will share my experiences and lessons learned while acting as the general contractor on my modular home in the St. Louis, Missouri area.When researching modular homes, I found a lot of information supplied by builders or sales agents of modular homes. I am trying to add another perspective to that - that of someone purchasing a modular home as well as being heavily involved in the planning and scheduling of the project.

Sections of the site include:

• background information

• a list of modular builders by state

• financing

• lessons learned

• pictures of all stages of the process

The site is barebones, but informative.

TV meets the Web. Bob Vila's website includes a library of short video clips from the show's Modern Modular series.

Also worth a mention: Bob Vila has his own blog, On The Level. Check it out!

Bob Vila's Home Again on the DIY Network just finished a run of shows about a modular home under construction. I haven't seen the show, but it sounds like there were some good views into the factory and site process.

From the episode descriptions: Modern Modular:

"Bob Vila travels to western Massachusetts for a brand new project; the construction of a modular home in the Berkshire Hills. He goes to the Simplex Industries factory in Scranton, Pa., to see how the process starts. We talk with owner Pat Fricchione, Jr. about the history of the company, and how the image of modular construction has changed over the years."Wall Panels:

"Today, we learn about the manufacturing process for the precast panels for the walls. Next, we travel back to the Simplex plant in Scranton Pa., where Bob Vila explains how each module is framed. Back in the Berkshires, the assembly process is explained once the panels have been lowered into place by crane."Assembly:

"At the Simplex plant, several crews work as if on an assembly line to make fast work of each module. There's a lot happening, from spackle and sand, to insulation, wall and roof sheathing, house wrap, and interior trim. Bob Vila learns about the state-of-the-art wire boxes that are being installed, and we'll look at the staircase that's being built for the front hall from the stair shop."

Simplex is also the manufacturer of the  Resolution: 4 Architecture models, like the home featured on the A Prefab Project blog.

Resolution: 4 Architecture models, like the home featured on the A Prefab Project blog.

A small picture of the home coming together can be seen on the Bob Vila web site.

The WIRED LivingHome we've covered before was first announced back in June. Two months later, the house modules are being installed and you can watch via webcam.

One gripe: I wish the webcam shots were all from a wider angle to show the big picture.

Treehugger's been watching:

"...sometimes watching paint dry is more exciting but then some big module flies in front of the camera."

Jetson Green also tuned in:

"All the main parts are supposed to be complete by September 7, and we'll be able to get a pretty good picture of what the final home will look like."

Curbed LA mentioned the home last Tuesday.

Equity Green discussed Hybrid Seattle, a prefab company building homes from shipping containers. They also showed off the ATC cabin, a prefab concept from Canada.

A blog simply called "House" covered the Empyrean  NextHouse blog, we've talked about before.

NextHouse blog, we've talked about before.

Preston at Jetson Green showed off the Ideabox Prefab:

"Ideabox offers a pretty cool product in the modern, prefabricated housing industry. Ideabox emphasizes good design, not square footage, and they make it easy to do."He also wrote about the JoT House.

The author at ColumbusING tried to spark debate about prefab:

"Can it be a viable solution? Over the past 10 years the country and for that matter Columbus has been inundated with the "cookie cutter" type of residential building, which has paved the way for convenient and affordable living for some and in the mind of others, has created a perception of architectural character digust. So where does that put Prefab houses?"

A New Zealand blog, Sneak, discovered the WIRED Living Home.

PrairieMod mentioned the blog at A Prefab Project:

"It's an interesting mix of photos, thoughts and information that anyone who dreams of going prefab will find very enlightening."

The Good Human's Prefab Wednesday wrote about the PLACE Houses, a new prefab concept. We'll cover those in more depth soon.

Inhabitat's Prefab Friday examined a student housing project made from containers.

Inhabitat's Prefab Friday covers the Zigloo Domestique, a container-based project in British Columbia:

The home is located in Fernwood, one of Victoria's oldest and funkiest areas, and proves that shipping containers are more than just modules for cargo transport or emergency housing. The designer has done a wonderful job of documenting the entire design process, from initial plans to delivery of the containers and final construction and furnishing. The project spans almost two years, and the final residence consists of 8 containers, 1800 square feet, and 3 stories of homey prefab space. Keith's family home design is a great example of shipping containers and prefab techniques as a viable and accessible building approach for just about anyone."

I for one cannot wait to see what it looks like all complete and ready to go!"

mkLotus at the West Coast Green building conference:

mkLotus at the West Coast Green building conference:

"It won't solve the housing problem here in the City but when West Coast Green occurs next month attendees will get a chance to tour a 'zero energy' Green home right smack in the Civic Center across from City Hall. Yes, it's a prefabricated house but not that nasty 'Prefab' often associated with temporary replacement for housing during and after WWII."

Green Options posted on the eco-friendliness of modular and prefab construction:

"Prefabrication and Modularity are new eco buzzwords on the menu this year. From homes to furniture, designers are beginning to employ new methods of construction and transportation to cut waste and energy consumption, ensure safety, and achieve greater overall methods of sustainability."

Check out these cool photos of a  Flatpak House being built.

Flatpak House being built.

(I'm assuming it's a  Lazor Office FlatPak though I've not been able to verify.)

Lazor Office FlatPak though I've not been able to verify.)

The NAHB (National Association of Home Builders) site includes a few resources on systems-built housing (yet another term for prefab, modular, or factory-built):

Fast Facts

• Panelized Homes (5/24/2007)

• Log Homes (1/11/2007)

• Modular Homes (1/11/2007)

Misc.

• Panelized Homes: What's Your Type? (10/6/2006)

• The Benefits of Panelization (10/6/2006)

Modular Home Photo Gallery

• Factory

• Set

• Exteriors

• Interiors

(One of the ongoing features that we're adding to the blog: a look back at prefab coverage over the past few years. These historic homes seemed like a great place to start.)

Last May the Wall Street Journal featured an interesting article on the Sears homes and the people who are working to find and catalogue them. The homes are some of the country's very first prefabs:

Precut houses ordered from a Sears catalog were shipped by boxcar in 30,000 pieces -- including shingles, nails and paint -- and assembled by a local carpenter or by the buyers themselves. Styles ranged from the elaborate, nearly $6,000 Magnolia, to the three-room, no-bath Goldenrod, sold in 1925 for $445. (Outhouses sold separately.)....

Sears also encouraged sales to families with steady wages but little in savings by financing up to 100% of some of the homes. But many homeowners were forced to default during the Depression, and sales came to an end in 1940.

The mail-order houses, many of which had big porches and were made from high-quality materials like early-growth cypress, were less expensive than architect-designed houses at the time, and were often all working-class people could afford. Because they were typically a family's first home -- and because they were often a do-it-yourself project for buyers -- the houses, enthusiasts say, are emblematic of the American dream.

It's difficult to know how many Sears homes are left. Sears doesn't have sales records, and while interest in catalog homes is growing, many people still don't know they are living in one...."

And check out the Sears Archives for more information on the Sears Homes.

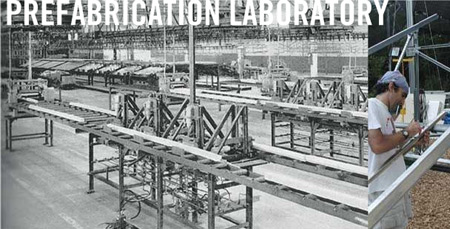

The Prefabrication Laboratory at the University of Texas at Austin has been investigating prefab methods since 2002:

"The Prefabrication Laboratory is a research group...focused on integration of factory production techniques and architecture. Offsite fabrication offers many benefits for building: higher quality, economies of scale, and more efficient use of resources. Prefabrication takes many forms and is evolving rapidly: modularization, pre-assembly, 'off-the-shelf' components....Our research investigates these changing processes looking for points of entry for architects....We look at fabrication in the larger context, how it has been used in the past, successfully or not, and how it affects local environments, cultures, economies."

The lab is similar to Studio 804 at the University of Kansas School of Architecture.

I know I have blogged a lot about A Prefab Project, but homeowner Chris has a lot of great advice. He does a great job of documenting and reflecting on the home-building experience. His most recent post chronicles the difficulties of the house delivery and set. I would not want to have been there for the house's trip up the steep driveway to the site:

"So while I watched the house bend (and wondered if it might actually just collapse), I really wanted to scream STOP and make everybody back up and start over, doing all the things we'd talked about doing. But that's a hard thing to know when to do, and an even harder thing to actually do."

Chris offers some advice for any homeowner setting out on a large scale project:

"The one lesson I keep coming back to in my mind from these episodes is the importance of the people you have working for you."

Find a modular home manufacturer near you:

"Use this directory to locate modular manufacturers across the country that can deliver your new home! Most modular manufacturers have local or regional representation or a network of builders to put the finishing touches on your dream home."

(NAHB = National Association of Home Builders)

Hive Modular has launched a blog to track important news and events.

Hive Modular has launched a blog to track important news and events.

One post links to a cool Google map locating all of the Hive Modular models in Minnesota.

Another notes that the set process we reported on "only took 2 hours to set the three boxes of the house and the client had a new home by lunchtime."

(Hat tip: Future House Now via Materialicio.us)

The folks over at A Prefab Project are having an exciting time, with the delivery and set of their prefab home.

A post on Friday announced the successful arrival of the module on site:

"After many hours on the road and seven flat tires, our house arrived at the site in WV a little after 6:30 Wednesday evening."

Luckily the module arrived in good condition with little damage:

"Well, good news is the house made it fine. No real issues - some minor drywall cracking, a couple of window locks popped during travel that will need to be replaced (not sure exactly what will need to be replaced - Simplex will let me know). Structurally, the house came through great. Window panes are all intact, the loose materials that shipped inside the box didn't do any damage, and no water got in."

On Monday, the house was finally set:

"No attempt at a witty title - I'm too tired. But everything went great. The set was a breeze. Only really took about fifteen minutes to actually lift, move and set the box (and about six hours to set up and break down the crane)."

Homeowner Chris also gave a detailed and useful look at the foundation work that occurred prior to the module's arrival.

EcoUrban is a new prefab home builder based in St. Louis. Owner Jay Swoboda keeps track of the company's home projects in a blog.

For EcoUrban's first project, 3140 Pennsylvania Avenue in St. Louis, EcoUrban partnered with modular builder Contempri Homes:

"After what felt like decades of anticipation and wait, it took just six days after the first pieces of wood were nailed together in the factory for the units to be delivered. Our units arrived at 10 AM this morning and the 60 Ton crane that lifted them into place was packed up and gone by 2 PM. We had a nice crowd gather to watch the four "boxes" come together and by the end of the day we were weather tight and secure."

Other posts cover the foundation work and visiting the modular factory.

Currently, the company offers a single 1,600sf floorplan, but "if you are passionate about an EcoUrban Home and not crazy about our floor plan then we will passionately find a floor plan to match you and your lifestyle."

With a focus on green, it's no surprise that EcoUrban "is aiming for LEED Silver certification, at the very least, for all future homes."

(Hat tip: Jetson Green.)

It amazes me how many companies offer some sort of modern shed. We've covered prefab sheds and other small houses in the past. Now there's a blog to satisfy your every prefab-shed desire!

Alex Johnsons's Shedworking is "the only daily-updated guide to the lifestyles of homeworkers in sheds and shedlike atmospheres around the world." Not all of the sheds featured are prefab, but the UK site is still worth a look.

The TS1 got an enthusiastic recommendation from Shedworker:

"The building is everything you'd expect from a timber flatpack (modular, customisable, portable, flat packed, renewable, recyclable, and with low emission materials) except it's built around a lightweight Smorgon stainless steel framework and PIR panels made from a fire-resistant urethane foam. It is, give or take a few cms, a 3m cube with adjustable legs and you can add modules together to make it bigger. A solar power system is optional."

Links: Smorgon stainless steel; PIR (Polyisocyanurate) by Stancold

By coincidence, I received an email from Alex while working on this post. I'll give him the last word:

"I also produce a bimonthly pdf magazine called The Shed for people who work in sheds and shedlike atmospheres. At the moment I am organising the first National Shed Week in the UK in collaboration with www.readersheds.co.uk."

(Hat tip: Future House Now featured a few models in a recent post.)

I've been reading more about Yurts, and I'm beginning to be won over.

The Yurt Foundation lays out the key advantages:

Yurts are special because they are portable. Central Asian nomads put their gers up in an hour or less. Modern canvas yurts can be set up in a day. To have a shelter that can be put up quickly and then taken down and moved as one's situation changes is a distinct advantage in our transient culture."

Wikipedia includes some great photos of traditional Mongolian yurts. This French company has even more photos showing the traditional process for making yurts by hand.

A blog called Nashville Modern Prefab covers the process of building a modern prefab by  Hive Modular. The project is nearing the end of the design/approval stage; recent posts have dealt mainly with permit and zoning approvals and provide a good first-hand look at how some municipalities make building a unique home difficult.

Hive Modular. The project is nearing the end of the design/approval stage; recent posts have dealt mainly with permit and zoning approvals and provide a good first-hand look at how some municipalities make building a unique home difficult.

A post back in December laid out the different approvals they would have to receive for the design:

The upshot of all this seems to be that even with a house that meets zoning (MUN - Multi-Use Neighborhood) and fits the Neighborhood Design Plan for our lot (Neighborhood Urban) we will still need to jump through many hoops to satisfy all of these people just for the sake of making these petty bureaucrats feel powerful."

"Initial unofficial feedback from members of the Historic Commission and the Design Review Board mentioned major concerns with: 1 - The lack of a front-facing entrance. 2 - The lack of a front porch. 3 - The materials in general and the metal siding in particular. 4 - The flat roof."

A post in February provided a view of the home's final design. The following is the animated fly-by video of the home's exterior (1:09, no sound):

In April, the home received approval from the Design Review Board:

"...They asked a lot of questions and I answered a few of [them]. Luckily some of the people on the board were able to answer some of the questions for me just be looking at their copies of the plans. The only changes that they require to the design are on the windows for the North side of the house - a larger window in the front upstairs bedroom and one more small window near the base of the stairs. Could have been worse. They approved with conditions so we are ready to actually get started for real."

(Hat tip: Jetson Green covered the site last week)

Jetson Green discovered a unique combo of free internet technologies that helps you to display a home by  MKD on your plot of land. Some of the applications involved, primarily Google SketchUp, require a bit of know-how.

MKD on your plot of land. Some of the applications involved, primarily Google SketchUp, require a bit of know-how.

Preston's post inspired a couple others. Materialicious explained why architects should love the "mash-up":

"What a great idea! Rather than bother the architect with endless queries like 'Can we change this?' or 'Can I have that?' or 'I don't like this, take it out', you can save time and money doing it yourself, tweaking the design (within certain limits, to be sure) and then presenting the desired customization to the architect. Makes sense to me."

Treehugger offers additional details:

"Google also offers Google Earth and mashed it and Sketchup so that you can put your Kaufmann design on your own property, play with the shadows and orientation, get comfortable with the plans and elevations before you even send her an email."

See also:

• MKD in the Google 3D Warehouse

• Other prefab options in the Google 3D Warehouse

• Google SketchUp

• Google Earth

Jean Prouve's Maison Tropicale doesn't go on the auction block until next week. The vintage prefab stirred up a little more press this week. Luxist covered the home and linked an article in the Queens Tribune.

Treehugger brought a couple other treehouse companies to the table:

"If you want to live out your childhood fantasy of moving into your treehouse (and preferably seceding from the family), but a couple of planks slapped together with some rusty nails isn't going to cut it, you'll want to give the able carpenters of TreeHouse Workshop a ring."

Inhabitat's Prefab Friday shared thoughts and more good photos of Richard Rogers' Oxley Park Houses that Treehugger mentioned last week:

"The homes' most innovative feature is the 'EcoHat,' a roofing system that allows hot air to rise and consequently be reused to provide passive solar water heating, thereby mitigating the energy consumption of the house. Clever floorplans optimize natural lighting schemes, while prefab modules and flat-pack components reduce waste and energy..."

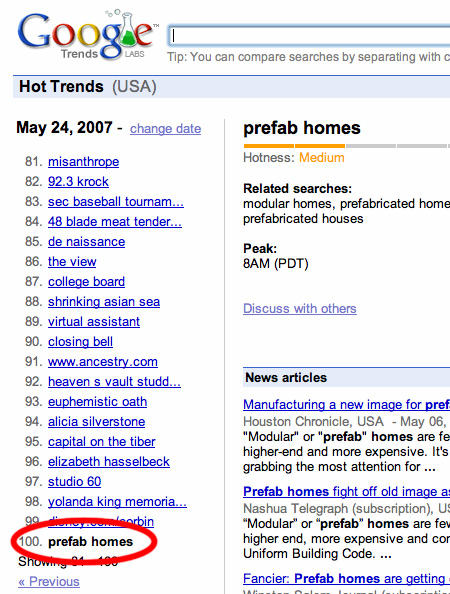

On May 24th, the search "prefab homes" ranked 100 on Google Hot Trends, "a list of the current top 100 fastest-rising Google search queries in the U.S." That's A LOT of searches...

Update: After some research, it seems that much of what shows up on google hot trends comes from daily crossword puzzles (that's why the entries seem so strange sometimes). But, a quick search didn't turn up the clue "prefab homes" on any crossword puzzles for the date.

When we first covered Jennifer Siegel's  OMD, their website barely worked. I'm happy to report that it's much improved.

OMD, their website barely worked. I'm happy to report that it's much improved.

The site is definitely worth a visit. It includes details on prefab homes that are completed or in progress. For example, here's a video (4:11 minutes, no audio) of the Pacific Palisades Prefab.

I just found a Yahoo! Group dedicated to sharing the thoughts and experiences of  LV Series homeowners. LV Series homeowner Gregg started the group in July of 2005:

LV Series homeowners. LV Series homeowner Gregg started the group in July of 2005:

The reason I am starting this group is because I have had a lot of questions during this process to which I could not find answers on the web -- the most notable example being the actual cost....I felt it would be a good idea to have a forum for people interested in the home to be able to ask around."

Foundation: +3300 Framing and roof: +5000 Heat, Plumbing, Elec: +1500 Interior Finish: +400

...It fell very close to Rocio's estimate, and I am in one of the most expensive areas of the country."

One user, having just finished his LV Home posted a full recap of construction costs, photos and thoughts on the project:

"Note that we did not encounter any big problems during construction. I will say that we were not pleased at all with the costs and do blame our contractor for a lot of the cost madness. But when we solicited bids more than one builder said, "kit or no kits, the cost per square foot will be the same." And that bore out to be true."

If you want to build an LV home, this is definitely a must-visit site.