An interesting story from Ball State University in Muncie, Indiana:

Michael Gibson recently finished a building prototype that utilizes prefabrication techniques in a way that has never been done before....

Gibson's plan included two standard prefab walls and two experimental walls he called lattice walls that were made of plywood instead of the standard dimensional lumber, which he said wastes materials. The lattice walls also used less material because of an assembly form called nesting, in which several lightweight boards nest together in a V-shaped fashion.

"The beautiful thing about the lattice walls and how they nested together was that they used less nuts and bolts," Gibson said. "They were also very lightweight, and the pressure from the roof was pretty evenly distributed, which prevented the structure from racking."

Most of the companies we track use a small number of accepted framing techniques. Some use SIPs:

Others use traditional framing (whether wood or steel):

-

Rocio Romero

Rocio Romero

-

Marmol Radziner

Marmol Radziner

-

LivingHomes

LivingHomes

-

Alchemy Architects

Alchemy Architects

-

Empyrean International

Empyrean International

-

Hive Modular

Hive Modular

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

And a few use unique metal framing systems:

Worth noting: the plywood framing system used in the  BURST* model, currently on view at MoMA's Home Delivery show, used a similar plywood framing system.

BURST* model, currently on view at MoMA's Home Delivery show, used a similar plywood framing system.

Last week, Lloyd Alter wrote about  KieranTimberlake's

KieranTimberlake's  Cellophane House ... which reminded me that we hadn't yet covered it in detail. The home is one of the five in MoMA's Home Delivery exhibition.

Cellophane House ... which reminded me that we hadn't yet covered it in detail. The home is one of the five in MoMA's Home Delivery exhibition.

Referencing a talk given by Steven Kieran and James Timberlake a few years back, Lloyd explained why the Cellophane House is so exciting:

I saw that prefab wasn't just about building in a factory, but was about reinventing the way we build, not just where.

...

"Chunking" is what car manufacturers do; they have subassemblies that are put together into modules, and then put together into the finished product. Builders already do a bit of that, buying pre-hung doors and nail-in windows. KieranTimberlake take it to the next level on the Cellophane House.

Visit Treehugger to read Lloyd's complete post.

Here's more info from the KieranTimberlake project page for the home:

Cellophane House is a five-story, offsite fabricated dwelling... The 1800 square-foot residence has two bedrooms, two bathrooms, living and dining space, a roof terrace, and a carport.

Like their  Loblolly House, this one is designed to be easy to put together and take apart.

Loblolly House, this one is designed to be easy to put together and take apart.

Cellophane House relies on a system of customizable elements. An aluminum frame serves as a matrix on which other factory made elements like floors and ceilings, stairs, bathrooms, and mechanical rooms can be attached. The aluminum structural framing is bolted, rather than welded, allowing it to be taken apart as easily as it is assembled. Moreover, this frame allows any of the walls, floors, structure, or envelope to be replaced at any time, without invasive modifications.

They describe the concept using soaring rhetoric:

A building is, at root, nothing more than an assemblage of materials forming an enclosure. We recognize that these materials came from somewhere, are held together for a time by the techniques of construction, and will at some future time transition into another state. While we tend to think of buildings as permanent, they are in fact only a resting state for materials, a temporary equilibrium that is destined to be upset by the entropic forces that drive the physical universe.

Definitely worth a view: a time-lapse video of the home's assembly.

I'll give Lloyd the final word (as I'm inclined to agree):

[The Cellophane House is] a demonstration of pushing the technological building envelope to the very edge; like so many things that came out of the space program that are now part of our everyday life, there are ideas here that in ten years will probably be part of every building.

Yesterday we mentioned the EPA's Lifecycle Building Challenge. We're most intrigued by last year's winning student entry, Texas A&M's groHome:

Using a library of pre-manufactured components brought to a site and assembled efficiently, the structure is designed with a specialized bolted connector [joint] that allows for components to be unplugged easily and without damage. Radio Frequency Identification Tags (RFID) can be embedded to take inventory and check the history of components.

More detail on the "gro(w)ability" of the home:

The plug and play concept is taken from the computer industry. .... The chrysalis of this idea is in our joint, the groJoint. It is designed to receive a beam on four sides and column or foundation on the top and bottom. Connections are all bolted which allows for components to be "unplugged" easily and without damaging the component....

The Texas A&M Solar Decathalon Website has more background information on the team and the project.

A few of the prefab companies we cover already use similar standardized systems:

We missed this item last year when we covered West Coast Green 2007: the EPA's Lifecycle Building Challenge. From a West Coast Green email:

... a design competition for students and professionals focusing solely on innovation regarding deconstruction and building material reuse.

And the Lifecycle Building Challenge was born! Submissions from architects, students, planners and builders poured in, ranging from de-nailer guns to radio-tagged, re-useable wall panels to design that considers reuse as it's primary function.

The awards were presented last year at West Coast Green.

The Challenge returns to this year's show. The ability to take apart a building and re-assemble it elsewhere seems like prefab in its purest form.

Update: The model appearing in the MoMA show will be the BURST*008.

SYSTEMarchitects'

SYSTEMarchitects'  BURST*003 house is the third prefab model featured in the MoMA prefab exhibition.

BURST*003 house is the third prefab model featured in the MoMA prefab exhibition.

Artdaily provides some details:

Designed to be assembled on site from laser-cut pieces, the Burst *003 house is a computer-designed remake of the typical prefabricated box. Working from a computer formula that automates the specific pieces needed to create the house desired, the project is based on a system that can be adapted to a changing set of criteria. The 2003 prototype of the Burst *003 project was built on Australia's Northeast coast, and won the Royal Australian Institute of Architects 2006 Wilkinson award.

Architecture Australia explains further:

Laying out the plywood pieces was achieved using the software program used in garment manufacture with very little wastage. While high technology is used throughout the design and manufacturing process, low technology is intentionally employed for assembly and for maintenance. Assembly requires fewer skills but intense cooperation and concentration. The building was put together by architecture students in something akin to a barn raising. The architects are fond of this image, yet recognize that the design’s reliance on numbers of enthusiastic and sympathetic cheap labourers will make it less desirable for some.

This fabrication method reminds me of the yourHouse. The process is explained through images and text on the SYSTEMarchitects site:

Plywood cut by a computer-controlled laser. Delivered to site in sheets with the ribs numbered, scored, and holes cut.

Laser cutting 1 of 400 sheets.

Sorting 1,100 pieces of laser-cut plywood.

Underside of floor structure.

Laser-cutting efficiency -- the total waste from the plywood sheets.

I can't help but be excited for the potential of the BURST* system and look forward to seeing the home at MoMA.

This video has been getting a lot of attention; it has 739 Diggs and counting.

The company is known as MasterFit in the US and MetalFit in Japan. However, the only website we can find for the company is the Japanese site. (Google translation)

Treehugger saw the system a couple years back:

"The components of the house are actually numbered, and are constructed as you would a piece of kit furniture. Materials cost 10-20% more than those for conventional framing, but the cost is offset by reduced labor expense..."

The "no tools" approach is similar to the  kitHAUS system, except with wood members. Both systems enable relatively unskilled laborers to frame an entire home.

kitHAUS system, except with wood members. Both systems enable relatively unskilled laborers to frame an entire home.

The NAHB (National Association of Home Builders) site includes a few resources on systems-built housing (yet another term for prefab, modular, or factory-built):

Fast Facts

• Panelized Homes (5/24/2007)

• Log Homes (1/11/2007)

• Modular Homes (1/11/2007)

Misc.

• Panelized Homes: What's Your Type? (10/6/2006)

• The Benefits of Panelization (10/6/2006)

Modular Home Photo Gallery

• Factory

• Set

• Exteriors

• Interiors

Quon Modular is a semi-custom prefab system from Australia. Each room is a (mostly) self-contained module, measuring 5 m x 3.1 m (16 ft x 10 ft). Buy exactly what you need placed side-by-side, stacked, or each by itself.

Quon Modular is a semi-custom prefab system from Australia. Each room is a (mostly) self-contained module, measuring 5 m x 3.1 m (16 ft x 10 ft). Buy exactly what you need placed side-by-side, stacked, or each by itself.

Room options and prices:

•  Bedroom, ~$31,000

Bedroom, ~$31,000

•  Kitchen, ~$48,000

Kitchen, ~$48,000

•  Bathroom, ~$40,000

Bathroom, ~$40,000

•  Master Bedroom, ~$32,000

Master Bedroom, ~$32,000

•  Multi-purpose, ~$28,000

Multi-purpose, ~$28,000

Materialicio.us loves the concept:

"For me, this is the simplest, most efficient system yet devised for a customized, prefabricated house. Design your house using their standard components, place the order, and ten weeks later it's delivered."

Few prefabs offer such a flexible approach. The  weeHouse series from

weeHouse series from  Alchemy Architects allows for the addition of specialized modules, such as the sleepTight, but their modules vary in size.

Alchemy Architects allows for the addition of specialized modules, such as the sleepTight, but their modules vary in size.  v2world was offering a similar product in their

v2world was offering a similar product in their  v2shell, but last we heard, they were reworking their product line.

v2shell, but last we heard, they were reworking their product line.

(More coverage: Treehugger)

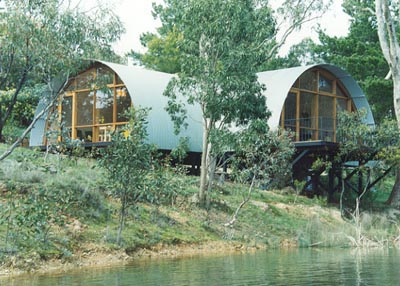

RAL Homes is a company in Victoria, Australia producing home kits that resemble Quonset Huts. The

RAL Homes is a company in Victoria, Australia producing home kits that resemble Quonset Huts. The  RAL Home kits can be combined in a number of formations, and even added on to your existing home. The kits consist of a series of pre-framed panels which join together to form an arch.

RAL Home kits can be combined in a number of formations, and even added on to your existing home. The kits consist of a series of pre-framed panels which join together to form an arch.

"The components arrive on site, complete with hardware and including an illustrated Assembly Manual. Two workers with a basic knowledge of Carpentry skills and standard tools simply bolt panels together. The external Colorbond corrugated steel roofing and leaf-free guttering system make RAL Homes virtually maintenance free."

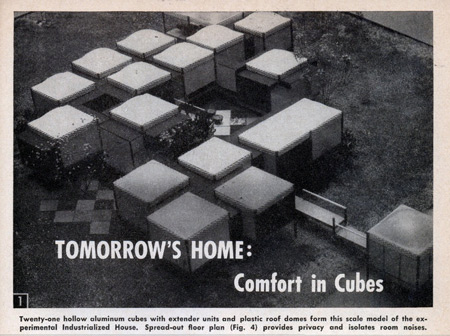

Back in 1960, designers George Nelson & Co. "threw out the old-fashioned and inefficient ideas inherent in many of [the day's] conventional houses." The design took advantage of the growing modern movement. One can easily see parallels with today's prefab ideals:

"They concentrated their thinking on greatly improved performance, mass production materials, extreme flexibility and a minimum of building parts..."

The Industrialized House featured:

• small modular cubes, combined with "extender units"

• "assembly-line built and put together quickly on site"

• lightweight anodized aluminum

• a screwjack leveling system for uneven ground

• easily disassembled and moved to another site

• translucent plastic tops

Large homes would be formed by assembling a number of the cubes in large groupings, with air space between:

"... to provide the utmost in privacy and quiet ... Nelson's solution was to separate the rooms and join them by corridors made of the smaller extender units. Since the cube house offers complete design freedom, it can be perfectly adjusted to the building site to provide the desired seclusion and quiet."

While the Industrialized House never caught on, similar structural systems shows up in more recent prefabs, like the  kitHAUS or the steel-framed modules of

kitHAUS or the steel-framed modules of  Marmol Radziner.

Marmol Radziner.

(Hat tip: Science and Mechanics Magazine (out-of-print) via Modern Mechanix via Materialicio.us)

We've reported on disaster relief housing before. Prefab methods are ideally suited for quick, cheap housing in far flung, resource-starved areas. An organization named CalEarth (California Institute of Earth Art and Architecture) has developed a method of home building that requires little more than the earth present at a homesite.

CalEarth's designs are based on a proprietary product called Superadobe Earthbags. The bags come in widths ranging from 12" to 26" and can be ordered up to a mile long. Combined with barbed-wire and earth from the site, the bags create super-strong structures:

"To build simple emergency and safe structures in our backyards, to give us maximum safety with minimum environmental impact, we must choose natural materials and, like nature itself, build with minimum materials to create maximum space, like a beehive or a sea shell. The strongest structures in nature which work in tune with gravity, friction, minimum exposure and maximum compression, are arches, domes and vault forms. And they can be easily learned and utilize the most available material on earth: Earth."

CalEarth has experimented with a number of designs and implementations using Superadobe, ranging from the Eco-Dome house, aka the "Moon Cocoon", to emergency shelters. Features of the Eco-Dome include:

• Built from local earth-filled Superadobe coils (soil-cement or lime-stabilized earth).

• Tree free.

• Can be repeated and joined together to form larger homes and courtyard houses.

• Can be built by a team of 3-5 persons.

• Designed with the sun, shade and wind in mind for passive cooling and heating.

• Solar energy and radiant heating may be incorporated.

(Hat tip: Inhabitat shared a bunch of photos and thoughts on the design last week.)

Last week's Prefab Friday on Inhabitat covered an interesting project in the UK:

The Container City™ system uses shipping containers linked together to provide high strength, prefabricated steel modules that can be combined to create a wide variety of building shapes and adapted to suit most planning or end user needs.

This modular technology enables construction times and cost to be reduced by up to half that of traditional building techniques while remaining significantly more environmentally friendly."

Since then, the system has been used for residential, commercial and educational buildings. Projects range from the 7 container Music Studio to the 73 container Riverside Building.

Brand Avenue covered the system a while back:

"I appreciate how they acknowledge temporality: implicit in their no-nonsense construction, and the light ways they touch the ground, is the idea that the site can and will be cleared someday, and something else will take their place. In this way, they interact rather respectfully with context..."

YouTube has a clip from the History Channel's Modern Marvels about the home:

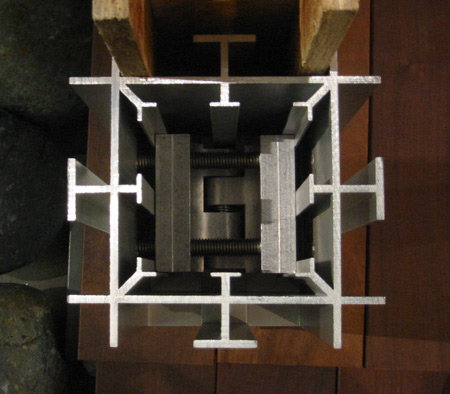

A while back, I wrote about the models from  kitHAUS. The product features an aluminum framing system called

kitHAUS. The product features an aluminum framing system called  MHS (Modular Housing System) developed by US Systems LLC:

MHS (Modular Housing System) developed by US Systems LLC:

"Our modules are constructed on site in a matter of days, not months, and because of [the framing system's] lightweight properties can get into the hardest [to] reach places, without heavy equipment."

I had the chance to see the system for myself at the CA Boom show, and thought it was quite impressive. Clamps are used to hold the structural members together; bolts are only used to tighten the clamps. The kitHAUS reps did inform me that power tools are necessary to tighten the bolts, as hand tools wouldn't achieve the proper torque.

The system manufacturer's website has images, and even a cool video (MHS.WMV at the bottom of the main page) to show how the system comes together. For those interested, there are detailed reports on the structural testing of the system.

Three prefab companies that exhibited at CA Boom in 2006 didn't return this year. Why not? Let's start with  Taalman Koch.

Taalman Koch.

I spoke with Alan Koch yesterday about their aluminum and glass iT House:

Why didn't you return to CA Boom this year?

"It was a lot of work last year and we didn't feel like it was our audience. Our house is a little more fussy than some. It requires a big leap of faith to live in an all glass house. It's not cheaper faster; it's a lifestyle choice. [Our audience is] a very niche market. It's not the general population, not even people interested in modern homes. It's about getting in touch with something - themselves or the landscape. It's a tool for reaching a new state."

I noticed you removed all information about standard models from your website, what is the plan there?

"We're not sure about the models and are reevaluating currently. Because of the way we were trying to offer the building before, we weren't really sure what it was. There was something about the way that it was presented that implied anything was changeable - that someone could build a 5,000sf iT House. It doesn't translate to that scale."

You and your wife have a variety of work in your portfolio, why prefab?

"We explore all kinds of things, stumble upon interesting things and do something with them. It's not exciting to just talk about problems architects are interested in. Prefab is not totally in the realm of the architect. We like and are satisfied by the process of figuring out prefab."

What do you think is one advantage of prefab?

"All the story that's published right now is 'modern and cheaper.' It is cheaper in a way; none of our clients could afford the design time we've poured into the house. Everyone who does buy an iT House gets the benefit of the hours of design time...for a cheaper price."

I understand that you are building an iT House prototype in the California desert. How is that going?

"We are almost finished with the model, and have done a lot of the work ourselves. We can't do everything, like roofing. But we did things like the frame. It was very simple to put together: 4 guys, 1 day, no skills and we had no problem setting up the whole frame. If you show the drawings to a contractor, they get worried because it's not something they know, so they tend to overcharge."

To find out more about the iT House prototype, check out the iT House blog.

Read more about the iT House in the blogs: Treehugger discusses the iTHouse's green properties. Inhabitat shares details about another iT House built in Orange County, CA.

kitHAUS takes a different approach to prefab than the other vendors at CA Boom 4. The

kitHAUS takes a different approach to prefab than the other vendors at CA Boom 4. The  kitHAUS models feature a patented lightweight aluminum framing system with SIPs between the structural members.

kitHAUS models feature a patented lightweight aluminum framing system with SIPs between the structural members.

The custom clamping technique of the MHS (modular housing system) reduces site construction time to a few days. The lightweight aluminum can be assembled without heavy equipment, is resistant to rust and termites, and never needs to be painted.

Exterior cladding is offered in Zinculume (corrugated metal panels) or Ipe wood, both of which are weather resistant and durable. Interior surfaces come un-finished, requiring you and your local contractor to handle flooring and wall coverings, and all cabinetry, lighting, and other fixtures.

kitHAUS offers four standard modules, as well as 5 example configurations on their website. The standard building blocks are 17' square.  K1 features a loft;

K1 features a loft;  K2 has a flat roof. The

K2 has a flat roof. The  K3 module is smaller, at 9' x 13', and the

K3 module is smaller, at 9' x 13', and the  K9 module (an actual offering) is a 4' x 4' home for your dog. The configuration examples range from 512 sf to 768 sf, but it is possible to combine more modules to create a dwelling (or doghouse) of any size.

K9 module (an actual offering) is a 4' x 4' home for your dog. The configuration examples range from 512 sf to 768 sf, but it is possible to combine more modules to create a dwelling (or doghouse) of any size.

The kitHAUS system offers a flexibility that is unmatched by any other home at the CA Boom show. The lightweight framing system and ease of assembly allow the kitHAUS to go places other prefab can't. For instance, if your homesite is on an island, or up some windy mountains roads, the kitHAUS can make the journey.