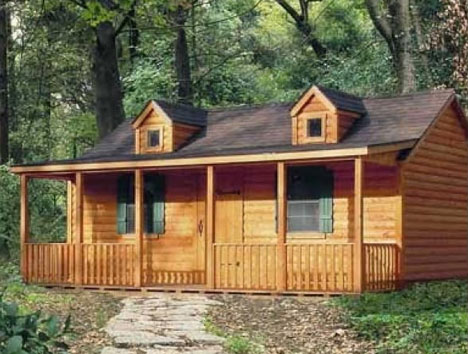

From a recent press release about  Spirit Cabins:

Spirit Cabins:

Don and Kristie Kinsey know firsthand the devastation a hurricane can cause. When Hurricane Katrina demolished their house in 2005, they decided to invest their insurance money in a home that would withstand future storms. After extensive research, the Kinseys chose the Boulder, Colorado-based company Spirit Cabins...The Kinseys were even more pleased with their decision after Hurricane Ike ripped through their Bay St. Louis, Mississippi neighborhood, destroying the area. Their home had survived fully intact.

More about the company:

Spirit Cabins combines old world craftsmanship ... with modern production technology in our state-of-the-art facility to produce fully assembled modular log homes and cabins... [They] deliver on-site nationwide completed modules customized to your needs that require little finishing work.

They offer three disctinct product lines:

And even furniture.

Other interesting pages on the company's website:

- the modular advantage

- a discussion of the difference between modular and manufactured homes.

Recently, Boston Magazine featured an article about the VH R-10 gHouse on Martha's Vineyard.

Why SIPs?

Because he couldn't be on-site every day, [Petrucci] decided to use a premanufactured structural insulated panel system built in a factory in New Hampshire and shipped to the site to be erected..."Prefab panels are a single stroke solution for structure and insulation, and they go up fast," says Petrucci. In fact, it took just three days to get the entire structure up.

Also worth noting: Petrucci is the director of the School of Architecture and Landscape Architecture at Arizona State University.

Read the entire article for more details.

(Hat tip: materialicious on October 20, 2008)

Architectural Record shared an online excerpt of an April 2008 article about the VH R-10 gHouse on Martha's Vineyard.

Where did they come up with the name?

- VH = Vineyard Haven, the town on Martha's Vineyard where the house is located

- R-10 = the zoning district

- gHouse = guest house

[The house was] so profoundly shaped by local restrictions that it adopted the zoning district—R-10—as part of its name.

The local restrictions seem tight:

Guesthouses in the district...may encompass no more than 600 square feet, their height may not exceed 24 feet...the basement may not be accessed from the building’s interior.

But the architect managed to work around them:

The small loft and spacious lower-level guest suite do not count toward the square footage allotted by zoning so, cleverly, 600 technical square feet become 1,000 square feet of livable space.

Details on the house:

Be sure to check out the images:

We're still catching up on news from last month. Here's a story worth covering:

Homes for Our Troops is a non-profit organization that provides homes to military personnel with severe injuries or disabilities sustained in active-duty wartime. Tidewater Modular Homes of Virginia Beach teamed up with Nationwide to provide the house for Bartlett, which will be set on its foundation in Chesapeake on Veteran’s Day Nov. 11.

Bartlett, who lives in Norfolk, came to Martinsville on Wednesday for a reception at Nationwide. He toured his future home in progress, stepping through the rooms on a $110,000 pair of prosthetic legs.

His new modular home is 1,475 sf and handicapped-accessible.

Some links:

- more details

-

Tidewater Custom Modular Homes is the local builder

Tidewater Custom Modular Homes is the local builder

-

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

- Homes For Our Troops accepts donations

(Hat tip: Charles Bevier of Building Systems on October 24, 2008)

A couple of weeks ago, materialicious covered Kathy Tafel's KTainer project:

With partners, I own land in a remote part of California. It has wild beauty, and some need of environmental restoration. Our first years there were spent in basic infrastructure such as water and road. To be there on a more regular basis, though, we needed to not spend hours setting up and tearing down a tent each time we visited. My partners built a yurt. I am building a house framed by shipping containers.

According to her website, the KTainer house was made from 4 24' containers which she purchased on Craigslist.

Also on the site, she details the process throughout various stages of construction and shares pictures:

- Overview, including a list of "not its", ie. containers that she did not choose

- Layout

- Site

- Foundation

- Openings

- Deck

- Kitchen

- Roof

- Ladder

Her conclusion:

there is far more romance in the idea of a shipping container home than the actuality of building one. Working with metal is a pain. You need to know metal-working skills or someone who has them. It is dangerous to work with power tools of course, but angle grinders and welders are especially not for the faint of heart. I am of course happy with the result, but this has been harder work than I imagined, and I didn't do the hardest labor.

If you are interested in shipping container homes, or considering building one yourself, Kathy's site is a must-visit.

The winners of the second annual Lifecycle Building Challenge (LBC2 or LBC 2008) were announced recently. About the challenge:

Lifecycle building is designing buildings to facilitate disassembly and material reuse to minimize waste, energy consumption, and associated greenhouse gas emissions. Also known as design for disassembly and design for deconstruction, lifecycle building describes the idea of creating buildings that are stocks of resources for future buildings.

Given those goals, it's no surprise that the three winners in the Building category are prefab:

TriPod by Carnegie Mellon University

TriPod is a prototype house demonstrating the "Plug and Play" concept and is designed to provide an innovative alternative to the currently unimaginative housing industry. ... [A] mechanical "core" ... acts as a motherboard that is able [to] accept multiple "pods" that are living, cooking, and sleeping spaces. This modular design allows homeowners to change their homes by adding or subtracting pods to suit their needs over time.

The Workshop by Schemata Workshop

There are two units in the building — in the first iteration the first story is an office; the second is an apartment. The building is elevated on concrete piers and cantilevers over an existing structure on-site

Loblolly House by

Loblolly House by  KieranTimberlake Associates.

KieranTimberlake Associates.

(See our previous coverage of Loblolly House.)

The challenge is sponsored by West Coast Green, U.S. Environmental Protection Agency, Building Materials Reuse Association, American Institute of Architects and Southface.

(Hat Tip: Jetson Green on October 29, 2008)

The goal of prefab is clear:

For more than a century, architects and builders have strived toward a prefabricated, industrialized house, one made in a factory so that economies of scale would be realized and the product would be affordable to all home buyers.

It's worth remembering that the current "stick built" process was itself an important innovation, "prefabricating" the basic components:

Until the 1830s, most houses in America were built with post and beam framing. All the pieces were hand-hewn and held in place with complex joinery, and home building was a time-consuming, costly process. Around then, however, steam-driven saws that could produce large quantities of accurately sized building lumber and machines that made huge quantities of iron nails began to appear in the larger cities.

An enterprising Chicago building contractor, George Washington Snow, saw the potential for these new products to revolutionize the building industry. He devised a method of framing that was much faster and far less costly.

One step forward in the meantime: panels (6% of homes built in the US in 2007).

the 2-by-4 stud walls sometimes are assembled in factories and hauled to a job site, an approach called panelizing.

A bigger step: modular (3% of homes built in the US in 2007).

a method of building in a factory an entire conventional wood-framed house in sections, loading each one onto a flatbed trailer, trucking it to a job site and then setting it in place with a crane.

Read the whole article for a few details on pros, cons, and possible futures.

Last month, The Daily Telegraph in the UK compiled a list of prefab products, describing them as

a burgeoning crop of 'instant' homes that take the prefab to a whole new level.

Included on the list:

| model | designer | ||

|---|---|---|---|

| The Loft Cube | Werner Aisslinger | ||

| 39-55 sq m (420-592 sf) |

£63,500 - £88,500 ($95,496 - $133,042) |

||

Micro Compact Home Micro Compact Home |

Richard Horden of  Horden Cherry Lee Horden Cherry Lee |

||

| 2.6 m cubic units (8.53 ft) |

about £26,000 ($39,086) excluding installation |

||

| Homes 2 Go | Dutch company Spacebox, brought to Britain by Benfield ATT Homes | ||

| 18 sq m (194 sf) |

£22,950 ($34,500) excluding delivery |

||

| Weberhaus | |||

| 200 sq m (2,153 sf) |

from £300,000 ($450,990) | ||

M-house M-house |

Tim Pyne | ||

| 100 sq m (1,076 sf) |

£147,500 ($221,736) | ||

| Eco Pod | Aidan Quinn of Eco Hab | ||

| 28 sq m (301 sf) |

£30,000 ($45,099) | ||

Read the full article for pictures and further details.

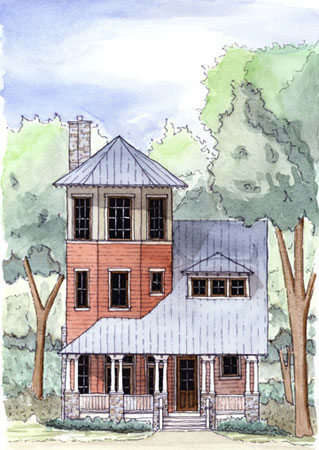

Here's an interesting modular development that was announced last month:

Haven Custom Homes ... and Sanctuary Communities have begun construction on the first home in Sanctuary Village, a Traditional Neighborhood Development (TND) located in the western mountains of North Carolina ...

Sanctuary Village will be a walkable, mixed-use village that will encompass 24 acres of multi-generational living with mansion flats, village houses, tree houses, mountain cottages and a civic/commercial component that will include shops, cafes, book stores, cultural events and community gathering spots a short stroll from homes.

We found this explanation of a Traditional Neighborhood Development:

a comprehensive planning system that includes a variety of housing types and land uses in a defined area. The variety of uses permits educational facilities, civic buildings and commercial establishments to be located within walking distance of private homes...

Haven Custom Homes emphasizes the advantages of building "in an off-site, climate controlled environment where the materials used in your home are protected from the weather."

- Precision construction resulting in straight walls, square corners, fitted windows and flat ceilings.

- Extra reinforcements in bearing walls.

- Move in 16-23 weeks after execution of a contract and your approval of final drawings and finish schedules.

Facts:

-

developers: Tim and Iva Ryan of

Sanctuary Communities

Sanctuary Communities

-

builder:

Haven Custom Homes

Haven Custom Homes

-

designer:

Allison Ramsey Architects (strategic partner)

Allison Ramsey Architects (strategic partner)

- location: "five blocks from Franklin's historic Main Street"

Links:

(Hat tip: Building Systems on October 29, 2008)

In September, Charles Bevier of Building Systems blog mentioned a 2-page spread in the Fall/Winter 2008 issue of Better Homes & Gardens' New Home Magazine (BH&G).

BH&G shines the spotlight on the Gull Island.... The design is one of many Poole has created for ... the Southeast market, homes that are turnkeyed by a network of authorized builders.

The blog post summarizes comments by Bill Murray, general manager of HandCrafted, on the advantages of modular construction:

- less time (120 days full turnkey versus 12 to 18 months for site building the old fashioned way)

- meticulous inspection

- modular units are constructed in the controlled environment and sealed from weather before shipping to the jobsite

The issue will be in newsstands through November.

Two weeks ago, the Christian Science Monitor featured Everhouse, a simple design meant to address the post-hurricane housing shortage near the Gulf Coast:

700,000 homes damaged ... and 250,000 homes destroyed

The designer of Everhouse looked to the advantages of prefabrication to help.

To keep costs down, the components of an Everhouse are made by a factory in Palatka, Fla., and then delivered to the land where each unit will be built. And like a desk from Ikea, the pieces arrive with all the necessary materials included...

They opted for a “panelized” design, because the concrete panels are easy to transport and give both the designer and homeowner a good amount of flexibility in house plans.

Key benefit: the shell can be assembled in one day.

The company hopes to produce 1,500 homes per year.

Sawyer also sees a shortage of skilled construction labor in the region. Read the article for his proposed solution.

From the husband and wife team at  Taalman Koch Architecture comes news of a small development of 3 iT houses: Three Junipers.

Taalman Koch Architecture comes news of a small development of 3 iT houses: Three Junipers.

Situated on 5 acres of pristine high desert landscape, each house offers an uninterrupted view of Pipes Canyon and the Pioneertown sawtooth peaks...

The iT house utilizes a "light touch" installation approach, minimizing the construction footprint through use of smaller scale, modular elements and minimal packaging material.

In tandem with that announcement, a new itHouse website has been launched with:

- iT house configuration options

- details on the framing system

- explanation of the on-site assembly

Also worth a look: an informative blog following the construction of the first iT house.

(Hat tip: Jetson Green)

Last month, the New York Times covered a new prefab home in Culver City, CA designed by  Sander Architects:

Sander Architects:

Inspired by the house that Charles and Ray Eames created in 1949 from a prefabricated steel frame and doors, windows and the like ordered from a catalog, the architects took the project on the condition that they could pursue a novel strategy. Besides using acrylic, Panelite, recycled steel and Styrofoam, they would try unusual ingredients like sunflower husks for wall panels and bookshelves, and blue jeans (for insulation).

Some facts about the house:

- 4,200 square feet

- 30 feet high (due to zoning)

- took 3 years to plan and construct the entire project

Final construction cost:

$528,000, only about a third of the going rate for architect-designed houses of this size in the Los Angeles area.

That comes out to about $125/sf. Not bad.

Check out a slideshow of the house (13 pictures). Read the entire article for more details.

Good Morning America's weather anchor, Sam Champion, recently reported from the Smart Home: Green and Wired exhibit at Chicago's Museum of Science and Industry. Check out their video and pictures. Though not mentioned there, the Smart Home is the  mkSolaire by

mkSolaire by  Michelle Kaufmann Designs.

Michelle Kaufmann Designs.

The exhibit runs through January 4, 2009. (See our earlier post for more info.)

Back in March, Swedish designer  Kjellgren Kaminsky Architecture and developer

Kjellgren Kaminsky Architecture and developer  Emrahus presented six prefabricated "passive" homes at the Hem & Villa housing fair in Malmö, Sweden, with a second presentation last month.

Emrahus presented six prefabricated "passive" homes at the Hem & Villa housing fair in Malmö, Sweden, with a second presentation last month.

Here's a paraphrase from Google's translation of the Emrahus home page:

The reason that we no longer need a heat source is that the house has well insulated walls and ceiling ... which retains the heat generated by household appliances, lights, TV set, and people who live in the house.

The houses:

| model | br | size |

|---|---|---|

| Villa VÄRDE | 3 | 1,292 sf |

| Villa Mittskepp | 2 | 1,722 sf |

| Villa Sida Vid Sida | 2 | 1,722 sf |

| Villa TÅRTAN | 4 | 1,862 sf |

| Villa Fixa | 4 | 2,045 sf |

| Villa Dragspel | 2 - 4 | 1,076 - 2,153 sf |

Blog coverage:

Dezeen on March 19th, 2008.

CubeMe on March 26, 2008

Best Houses and Home Design on March 30, 2008

Jetson Green on October 7, 2008

Inhabitat's Prefab Friday on October 17, 2008

In Italy,  Giacomo Guidotti e Riccarda Guidotti Studio di Architettura designed a home that uses prefabricated concrete wall panels as the exterior cladding. That's common in commercial and industrial buildings but rarely seen in residential construction.

Giacomo Guidotti e Riccarda Guidotti Studio di Architettura designed a home that uses prefabricated concrete wall panels as the exterior cladding. That's common in commercial and industrial buildings but rarely seen in residential construction.

One advantage of this method: the concrete forms both the exterior and interior wall surfaces, reducing time spent on finishes.

(Hat tip: materialicious)

The Swiss Architecture Museum included the home in an exhibition last year:

The Casa Grossi in Monte Carasso (2000-04) is particularly interesting. It is a narrow, rectangular building, a dwelling on the fringe of the building zone. This minimalist structure, clad with prefabricated concrete elements, conveys an impression of being hermetically sealed to the outside world, but surprises us with an atrium inside - serving as both a stairwell and an access core - lit from a roof light on the 2nd floor.

Here's some background information on prefabricated concrete wall panels from an excellent reference site called the Whole Building Design Guide.

Paul E. Gaudette explains:

Architectural precast concrete has been used since the early twentieth century and came into wide use in the 1960s. The exterior surface of precast concrete can vary from an exposed aggregate finish that is highly ornamental to a form face finish.... Some precast panels act as column covers while others extend over several floors in height and incorporate window openings...

In general, prefabricated concrete wall panels can serve one of two purposes:

Precast cladding or curtain walls are the most common use of precast concrete for building envelopes. These types of precast concrete panels do not transfer vertical loads but simply enclose the space. They are only designed to resist wind, seismic forces generated by their own weight, and forces required to transfer the weight of the panel to the support....

Load-bearing wall units resist and transfer loads from other elements and cannot be removed without affecting the strength or stability of the building.

It's not clear whether the Casa Grossi wall panels are load bearing.