Listen (~16:00) to a broadcast from New Hampshire Public Radio about the show, featuring an interview with Stephen Kieran of  KieranTimberlake Associates.

KieranTimberlake Associates.

Bloomberg Television's James Russell reviewed the exhibition:

... a wildly ambitious display of the pleasures and peculiarities of prefabricated houses. The prototypes, augmented inside the museum by a rich history of the genre, capture both the earnestness of architecture's obsession with industrial technique and its faith in technology as an agent of progress.

Read the whole thing for some specific criticism -- and possible upside.

USA Today offered an overview:

an engrossing survey of the prefab movement...

The New York Times profiled  BURST*08 and architects Jeremy Edmiston and Douglas Gauthier. The path to realizing the home was not an easy one:

BURST*08 and architects Jeremy Edmiston and Douglas Gauthier. The path to realizing the home was not an easy one:

... arranging all the parts into the right piles so they could just be snapped into place at MoMA turned into a logistical nightmare lasting weeks rather than days. While they sorted, the 15 or so architecture students on hand were trying to reassure the contractors about a model that looked as sturdy as a collapsible fan. As for the architects, they were running back and forth to their offices, scrambling to update the drawings and struggling to raise money.

The full chronicle of the home's construction is worth a read, but sadly, it sounds like we won't be seeing future prefabs from the pair:

For the two architects, however, the success is bittersweet. After nine years their partnership has ended. “This is our last project together,” Mr. Edmiston said.

New York Magazine's architecture critic also reviewed the show:

This sporadically exciting but ultimately diffuse show begins indoors, on the sixth floor, and sidles up on the present by way of the past. It opens, brilliantly, with both....an exhibit that can’t quite decide whether prefabrication should be treated with irony or exuberance.

Dwell reports:

...for those who can’t visit the city anytime soon, the museum now has an online version of the show, replete with installation videos, archival footage, and an interactive timeline of prefab housing.

Admittedly, clicking through Home Delivery can’t beat scaling the five structures that now stand in the museum’s adjacent lot. But it’s certainly the next best thing.

The online exhibition takes over the top portion of the blog. It's quite comprehensive; well worth a look.

Jetson Green wrote about Ideabox.

Ideabox has been busy adding ... Cubes to their product mix.... The cubes are 215 sf each and can be attached to Confluence Modern to grow the size a little bit.

JG also covered the Method Homes Cabin:

...Method Homes' first foray into green prefab is met with success as the home is complete -- it looks gorgeous and exudes the company's "Down to Earth Prefab" tagline. The cabin home is currently available for tours and, if you like it, you can place an order for your own.

Moco Loco also looked at the cabin:

The first prefab cabin by Seattle-based Method Homes (completed in 3 months) is based on a flexible template that allows for a full range of customization.

We'll take a more in depth look at both companies soon.

Inhabitat's Prefab Friday looked at two different unconventional prefabs. First, they covered strange treehouses from Our Planet Retreats:

Our Planet Retreats, an innovative UK-based company, is building eco-resorts in gorgeous pristine locations like the Phillipines, Vanatu, and Papua New Guinea. Visiting guests stay in simple floating spheres in the trees that are reached by spiral stairs. Crafted from fiberglass and built by locals, each sphere can accommodate up to 4 people.

They also wrote about EcoShack's Nomad Yurt:

...a beautiful soft-shelled structure that finds elegance in its simplicity.

(Dated Saturday but actually posted on Monday. Sorry for the delay.)

MoMA's Home Delivery exhibition opened this weekend. The blogs were full of coverage.

Voxant's TheNewsRoom includes a video report. (Note: the video is interesting -- but runs automatically, may be slow, and may cause browser problems.)

Zavod Big, a design blog in Eastern Europe, covered the "Touch" home from Kannustalo of Finland.

Green in Medusa featured some beautiful images of the show, plus this note:

Whether you like these architects and the concept of Pre-Fab or not the show is worth visiting.

Treehugger featured pictures last week and a look at several reviews on Monday.

Dwell shared some photos.

Core 77 showed off an image of a futuristic wall fragment at the show.

future forum 2008 included exquisite photographs, interesting discussion, and this conclusion:

HOME DELIVERY is an impressive narrative about both failures and successes of the concept. What is evident in the optics of the MoMA showcase is that prefabricated homes have evolved over the years and now come in astonishing variety and appeal to the most sophisticated expectations.

C-MONSTER.net also has photos.

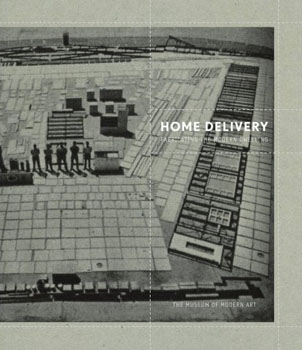

MoMA's exhibition catalog is available for purchase (Amazon, sale price $29.70), but won't ship until August 1.

The catalog includes three essays:

- "Home Delivery: Viscidities of a Modernist Dream from Taylorized Serial Production to Digital Customization" by Barry Bergdoll [curator]

- "Scandinavia: Prefabrication as a Model of Society" by Swedish historian and critic Rasmus Wærn

- "Postulating the Potential of Prefab: the Case of Japan" by Ken Tadashi Oshima, a historian of Japanese architecture.

Other contents:

- "substantial descriptive texts" of each of the 63 projects in the show, written by Peter Christensen

- contributions from guest authors Robert Rubin, Friedrich von Borries, and Florian Breipohl

- a chronology of prefabricated buildings

- a selected bibliography

Sounds like a must-have.

The blogs were mostly abuzz with news of MoMA's Home Delivery show this week. We'll provide a rundown of coverage early next week.

In other prefab news, Inhabitat's Prefab Friday looked at a community art center designed and built by Studio804 of the University of Kansas School of Architecture:

...this innovative building uses modular design with the length of long truck trailers as the defining width component measure - an outside the box thinking that makes larger prefab buildings possible.

Lots more info on the project page.

The New York Times architecture critic provided a glowing review of MoMA's Home Delivery in this morning's paper:

"Home Delivery: Fabricating the Modern Dwelling," which opens on Sunday at the Museum of Modern Art, is a delightful surprise....In a tour de force Mr. Bergdoll [the show's curator] was able to build five full-scale model houses for the show in a lot just west of the museum. The effect is startling: expressions of a suburban utopian world surrounded by Midtown’s looming skyscrapers.

Mr. Bergdoll has not only managed to track down some unexpected gems, he has also arranged them in a way that allows us to see them with fresh eyes. He makes a convincing case that prefabricated housing was both a central theme of Modernist history and a dream that remains very much alive today.

We've provided extensive coverage of the full-scale homes; this review adds details on the accompanying exhibits:

[the show] presents more than 80 projects, from humble experiments in suburban living to stunning works of cretive imagination.

Here's a sample: (plus some external links we dug up)

- wall fragments from architects Rahim, Hina Jamelle, Jesse Reiser and Nanako Umemoto

- One Week: "a 1920 Buster Keaton film in which fumbling young newlyweds try to assemble a prefabricated house"

- the Manning Portable Cottage: an 1833 prefab that "could be conveniently packed in a ship's hold and reassembled."

- the 1931 Copper House: "designed by the Modernist master Walter Gropius. It was conceived as a system of insulated copper wall panels that could be easily transported and assembled on site in 24 hours."

-

Jean Prouvé's Maison por l'Institutrice: "a reworking of his 1948

Maison Tropicale, a masterpiece of prefabricated design."

Maison Tropicale, a masterpiece of prefabricated design."

- the Lustron House: "modern technology draped as nostalgia"

- Archigram's 1965 Living Pod: "an amoeba-shaped capsule with mechanical systems plugged into the side"

- Kisho Kurokawa's Nakagin Capsule Tower, which was slated for demolition last year

- Primitive Huts by Wes Jones

- works from Greg Lynn and Teddy Cruz

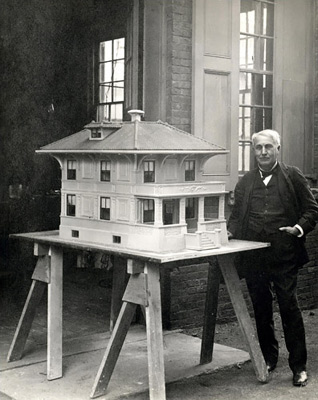

- Thomas Edison's Simple Concrete House System

Read the full article for more details and a new slideshow with 12 images.

One correction to the article: the frame of the  Cellophane House is aluminum not "lightweight steel."

Cellophane House is aluminum not "lightweight steel."

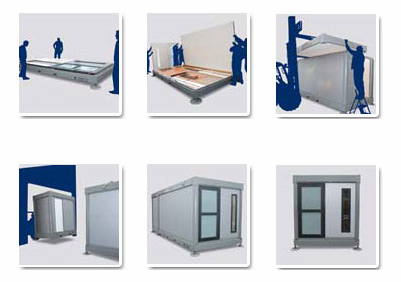

Abilmo produces and supplies prefabricated, "pop-up" hotel rooms for large events in Europe:

Far too many events lasting only a few days are faced with the challenge of ... accommodation which cannot be satisfied by the existing hotel capacity.

The solution comes in a small, efficient package:

Each room once folded measures: 4.40m x 2.38m x .468m [14.4' x 7.8' x 1.5']

Compact loading of 18 foldable multi-purpose rooms per truck.

Each room includes most of the comforts one would expect in a hotel:

- Ceiling hung with cloth, low voltage lighting, wood flooring, furniture in wood

- Area of 12 Sqm [130 sf]

- Thermal and acoustic insulation, individual heating and air conditioning system

- Individual bathroom with WC, shower and hot water

Abilmo's concept seems to have applications beyond hotel rooms. The concept of reusability is becoming more popular; we've seen a few examples in the past couple years. Most recently, we've reported on the groHome, winner of last year's EPA Lifecycle Building Challenge and  KieranTimberlake's Cellophane House. Both of these models embrace the idea of reusable building parts.

KieranTimberlake's Cellophane House. Both of these models embrace the idea of reusable building parts.

Treehugger seems convinced:

It is an interesting idea - why build an entire hotel for a big event when you can just move it around?

A video tour of the home:

Last week, Lloyd Alter wrote about  KieranTimberlake's

KieranTimberlake's  Cellophane House ... which reminded me that we hadn't yet covered it in detail. The home is one of the five in MoMA's Home Delivery exhibition.

Cellophane House ... which reminded me that we hadn't yet covered it in detail. The home is one of the five in MoMA's Home Delivery exhibition.

Referencing a talk given by Steven Kieran and James Timberlake a few years back, Lloyd explained why the Cellophane House is so exciting:

I saw that prefab wasn't just about building in a factory, but was about reinventing the way we build, not just where.

...

"Chunking" is what car manufacturers do; they have subassemblies that are put together into modules, and then put together into the finished product. Builders already do a bit of that, buying pre-hung doors and nail-in windows. KieranTimberlake take it to the next level on the Cellophane House.

Visit Treehugger to read Lloyd's complete post.

Here's more info from the KieranTimberlake project page for the home:

Cellophane House is a five-story, offsite fabricated dwelling... The 1800 square-foot residence has two bedrooms, two bathrooms, living and dining space, a roof terrace, and a carport.

Like their  Loblolly House, this one is designed to be easy to put together and take apart.

Loblolly House, this one is designed to be easy to put together and take apart.

Cellophane House relies on a system of customizable elements. An aluminum frame serves as a matrix on which other factory made elements like floors and ceilings, stairs, bathrooms, and mechanical rooms can be attached. The aluminum structural framing is bolted, rather than welded, allowing it to be taken apart as easily as it is assembled. Moreover, this frame allows any of the walls, floors, structure, or envelope to be replaced at any time, without invasive modifications.

They describe the concept using soaring rhetoric:

A building is, at root, nothing more than an assemblage of materials forming an enclosure. We recognize that these materials came from somewhere, are held together for a time by the techniques of construction, and will at some future time transition into another state. While we tend to think of buildings as permanent, they are in fact only a resting state for materials, a temporary equilibrium that is destined to be upset by the entropic forces that drive the physical universe.

Definitely worth a view: a time-lapse video of the home's assembly.

I'll give Lloyd the final word (as I'm inclined to agree):

[The Cellophane House is] a demonstration of pushing the technological building envelope to the very edge; like so many things that came out of the space program that are now part of our everyday life, there are ideas here that in ten years will probably be part of every building.

MoMA's Home Delivery show opens a week from tomorrow so it's been getting a lot of attention around the web.

The New York Times added a little article blurb to the slideshow they posted the other day:

Even by New York City standards, it’s quite a sight. On a 17,000-square-foot vacant lot just west of the Museum of Modern Art, a mini-suburb of contemporary houses is being built — practically overnight.

Lloyd Alter of Treehugger wrote a series of posts on the exhibition:

- Monday: the Digitally Fabricated House

-

Tuesday: the

BURST*008

BURST*008

-

Wednesday: the

System3 house

System3 house

-

Thursday: the

micro compact home

micro compact home

- Friday: the Cellophane House

HAUTE*NATURE took a green perspective.

We'll let Inhabitat's Prefab Friday have the last word:

get down to the MOMA to take in this fantastic prefab extravaganza.

We've been following A Prefab Project's construction of a  Resolution: 4 Architecture home since near the beginning.

Resolution: 4 Architecture home since near the beginning.

Over a year later, the home is complete and available to rent. It's an excellent opportunity to understand what a Resolution: 4 Architecture home can be. Homeowners Chris and Sarah have definitely put a lot of energy and care into the home, and it shows.

A few guests have been testing the place out over the past couple months. Chris shared some stories:

... all of the folks who have stayed so far have been superstars. John and Laura, our first guests, talked with me for an hour on the phone about their visit, and took copious notes. (And have already booked two more weekends!) Chris and Ritamary chipped in one of those wire brush scrubbers for the grill. Ross and Libby sent along a professional-quality blurb and a fancy corkscrew. And Jake, whose Herculean bicycle trip from Pittsburgh to our cabin really cannot be appreciated unless you are a biker.

Jake documented his bicycle trip to the cabin with a blog and great photos.

Our previous coverage of the project:

- the home was delivered and set about a year ago

- lessons learned in July of last year

- a budget update in August

Today the New York Times published an online slideshow documenting the progress of the homes in MoMA's Home Delivery exhibition.

Definitely worth a view.

We don't usually cover non-residential prefabs, but a quick blurb published in the The Times (UK) caught my eye last month:

Work has begun on Britain’s first flat-pack school, which is arriving in a convoy of 20 lorries from a prefab building specialist in Switzerland.

St Agnes CE Primary in Longsight, Manchester, will be built from ready-made wooden frames that cut construction time, saving hundreds of thousands of pounds. Six hundred computer-cut wooden panels will be added, to complete the three-storey building. The biggest panels weigh two tonnes and are 12m (36ft) long.

Manchester's Evening News provided a little more info and the above video:

The panels will be made in a factory near Lausanne in Switzerland which specialises in manufacturing pre-fabricated panels from sustainable forests nearby. Holes for doors, window and sockets are drilled in advance using precise cutting techniques.

Other advantages:

Designers say the specially-treated timber joists are even more fire-resistant than steel, which can buckle and break under high temperatures.

Last year we covered a house in the San Francisco area that used a similar system made by Thoma Holz in Austria.

I'm a little obsessed with the progress updates over at MoMa's Home Delivery blog. Not least: several of the videos are great -- but some of their best are hidden behind a proprietary interface.

Try this. In the top right corner of their blog, move your mouse over the image. With luck, a control bar will slide up a bit from the bottom. Click the tiny square icon on the right and notice that the hard-to-read gray text on a light gray background changes. In theory, that means you switched to another video. In practice, it's hard to tell since there's not much action in some of them.

The time-lapse installation videos are definitely worth a look -- though it would be much better if each video was in a separate post that bloggers could link to.

MIT's news office described the work of professor Larry Sass for MoMA's Home Delivery exhibition. (We covered details of his "Digitally Fabricated House for New Orleans" and the MIT yourHOUSE project back in January.)

Inhabitat's Prefab Friday took advantage of the holiday to talk about prefab and migration:

How can architecture reconcile the transborder pressures of providing adequate housing with the inevitable tides of hyper-immigration? How can it help manage the increasing sprawl of the destitute colonias swelling between the two countries? And how can we bring new models of planning and infrastructure to areas of booming migrant settlement?

Materialicio.us covered a new community of homes, built by Wieler, a company which we will cover in depth soon:

Nathan Wieler and his wife were the owners of the original Res4a Dwell House who worked with Dwell to set up the original competition, built the house, tried to sell the house but remained there, and went on to promote prefabs...

Yesterday we mentioned the EPA's Lifecycle Building Challenge. We're most intrigued by last year's winning student entry, Texas A&M's groHome:

Using a library of pre-manufactured components brought to a site and assembled efficiently, the structure is designed with a specialized bolted connector [joint] that allows for components to be unplugged easily and without damage. Radio Frequency Identification Tags (RFID) can be embedded to take inventory and check the history of components.

More detail on the "gro(w)ability" of the home:

The plug and play concept is taken from the computer industry. .... The chrysalis of this idea is in our joint, the groJoint. It is designed to receive a beam on four sides and column or foundation on the top and bottom. Connections are all bolted which allows for components to be "unplugged" easily and without damaging the component....

The Texas A&M Solar Decathalon Website has more background information on the team and the project.

A few of the prefab companies we cover already use similar standardized systems:

We missed this item last year when we covered West Coast Green 2007: the EPA's Lifecycle Building Challenge. From a West Coast Green email:

... a design competition for students and professionals focusing solely on innovation regarding deconstruction and building material reuse.

And the Lifecycle Building Challenge was born! Submissions from architects, students, planners and builders poured in, ranging from de-nailer guns to radio-tagged, re-useable wall panels to design that considers reuse as it's primary function.

The awards were presented last year at West Coast Green.

The Challenge returns to this year's show. The ability to take apart a building and re-assemble it elsewhere seems like prefab in its purest form.