The New Republic recently discussed the plight of prefabricated housing in the United States.

Technologically, there is no reason why houses, like cars, cannot be mass-produced, and in other countries they are constructed that way. Prefabricated, mass-produced homes, like mass-produced cars, offer myriad advantages. Fewer resources, material and labor, are wasted. Weather does not dictate construction schedules. Higher and consistent quality is more easily and reliably achieved, because the product is fabricated in the controlled setting of a manufacturing plant, with all the attendant cost advantages.

Consistent with their political leaning, they call for government to step in:

For quality affordable mass-produced housing to be built, we need to create different conditions for a mass market. A new legislative structure must clear away the obstacles presented by non-standard, municipally controlled building codes and create enforceable national standards for prefab-friendly, environmentally responsible manufacturing and construction practices.

The article is quite long, but worth reading.

Hat tips: Building Systems on February 21, 2009 and Apartment Therapy on February 26, 2009. The latter has an active comment thread, with a general consensus that price remains a major barrier.

A recent email from  Alchemy Architects says:

Alchemy Architects says:

We have now included more and lowered our prices! 2,000 SF weeHouses with Good Stuff are around $125/SF or less, leaving you extra coins to put into your site.

Old pricing was in the $150/SF range, so it's quite a drop. Actual pricing depends on your part of the country.

Also mentioned:

Order a weeHouse SMALL with an off-grid Solar Package before November 1, 2008 for only $99,000 [$109,000 for CA and other states west of Colorado]. Outfitted with Fusion's 720W AC Energy Kit, you only need to provide the foundation, well, and septic to have a completely finished retreat.

Higher capacity solar kits are available for larger homes. For details: FusionModular.com.

Sander Architects designs homes that use prefabricated steel skeletons. The Los Angeles Times discusses the advantages of steel:

Sander Architects designs homes that use prefabricated steel skeletons. The Los Angeles Times discusses the advantages of steel:

With costs below those of conventional building methods, quick and easy assembly and no termite issues, prefabricated or pre-engineered steel buildings are finding a place in the residential home market.

Homeowner Thomas Small explains part of his reason for choosing steel:

"Most of the metal in this house is recycled and will be recyclable at the end of its use in this house," Small said.

"And there's also very little waste with metal. It was made at the factory and then shipped here. There was no sawdust. No cutting," he said. "And we didn't have to hire specialized builders. It was built by the contractor who built the rest of the house, and bolted together very easily."

Firm principal Whitney Sander describes the process:

"It fits together like an erector set," Sander explained. "And it goes together in three weeks. The inside takes longer, but the prefabrication can save you months and thousands of dollars."

Some numbers from recent Sander Architects projects:

Two projects completed within the last year cost about $130 per square foot or about one-third of traditional custom residential costs, which can top $400 per square foot, according to Sander.

Small's construction costs were about $175 to $200 per square foot, compared with $120 to $350 for traditional non-custom homes, according to construction experts.

These sounds like impressive savings, though finishes and other construction unrelated to the steel skeleton play a large part in determining final construction costs. Read the complete article for more about Sander Architects and steel framing.

The Denver Post reports on a modular homeowner near Denver:

Jill Warner is having a new home built in Salida that's as green as possible without "going overboard," she said....

Warner wanted to buy a prefab home from the beginning, but her early research revealed a stiff price tag — about $320 per square foot using an out-of-state builder.

Then she dug deeper and found companies closer to home. That cut the price by more than half.

Warner found Northstar Homes, based in Loveland, Colorado. According to Hollis Hunt of Northstar:

...people incorrectly assume going green means a sizable price tag. He says homebuyers can make choices that won't break the bank.

Their site features some helpful resources, including a list of modular home myths.

Read the full article for other tips on how to build prefab and meet your budget. The article also updates readers on the MKD development in Denver that we've reported on previously.

Toll roads aren't just annoying to commuters; they can raise the cost of doing business:

A Pennsylvania law to toll Interstate 80...will have a devastating effect on Pennsylvania's modular housing industry, states The Modular Building Systems Association....Pennsylvania is the top producer of modular homes in the Northeastern United States and one of the top three (3) production states within the entire country. Approximately forty (40) percent of all homes produced in Pennsylvania are transported to other states and even if appropriately sized booths are placed at tolling areas, the toll fees and other related costs will add thousands of dollars to every home.

According to Don Shiner, President of DeLuxe Building Systems in Berwick, PA:

"The cost of our homes will increase not only because of the tolls imposed when we transport the finished home to the job site, but also on raw materials being delivered to our factories, employees traveling on company business, the return of empty undercarriages to the factories for reuse in transporting the next home, time delays in transporting our homes that will result from I-80 being a toll road and other, additional factors."

Link: Modular Building Systems Association

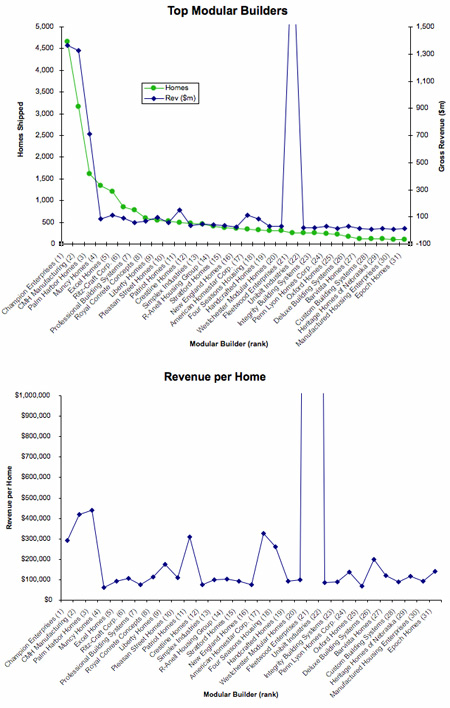

Last year, Builder Magazine released a list of the top 31 modular builders (pdf) in the United States.

I've put the data in the top chart above. As can be seen, a few large companies build the majority of modular homes. In case you don't recognize the shape of the curve: it's a classic "powerlaw" distribution known as Zipf's Law and discussed in the business bestseller The Long Tail. All sorts of data show the same shape, including book sales, blog traffic, and word usage in any language.

The second chart shows revenue per home for each company. There is lots of variation in this chart. It might be interesting to research this variation at some point. One likely factor: companies that sell direct vs. wholesale. Any other thoughts?

Fleetwood Enterprises builds a number of products, including recreational vehicles, so their revenues reflect revenue sources other than the modular homes shipped, accounting for the large discrepancies in the data.

Below, you can see a table that shows all of the data charted above for each company.

Company (rank) Homes Revenue ($m) Revenue per home Champion Enterprises (1) 4653 1365 $293,359 CMH Manufacturing (2) 3166 1328 $419,457 Palm Harbor Homes (3) 1614 711 $440,520 Muncy Homes (4) 1346 85 $63,150 Excel Homes (5) 1200 111 $92,500 Ritz-Craft Corp. (6) 849 91 $107,185 Professional Building Systems (7) 781 58 $74,264 Royal Concrete Concepts (8) 600 68 $113,333 Liberty Homes (9) 552 97 $175,725 Pleasan Street Homes (10) 526 57 $108,365 Patriot Homes (11) 490 151 $308,163 Crestline Homes (12) 480 36 $75,000 Simplex Industries (13) 452 45 $99,558 R-Anell Housing Group (14) 408 42 $102,941 Stratford Homes (15) 375 35 $93,333 New England Homes (16) 350 27 $77,143 American Homestar Corp. (17) 341 111 $325,513 Four Seasons Housing (18) 320 84 $262,500 Handcrafted Homes (19) 307 28 $91,205 Westchester Modular Homes (20) 305 30 $98,361 Fleetwood Enterprises (21) 261 2145 $8,218,391 Unibilt Industries (22) 253 22 $86,957 Integrity Building Systems (23) 247 22 $89,069 Penn Lyon Homes Corp. (24) 230 32 $139,130 Oxford Homes (25) 220 15 $68,182 Deluxe Building Systems (26) 165 33 $200,000 Barvista Homes (27) 125 15 $120,000 Custom Building Systems (28) 121 11 $90,909 Heritage Homes of Nebraska (29) 121 14 $115,702 Manufactured Housing Enterprises (30) 106 10 $94,340 Epoch Homes (31) 100 14 $140,000

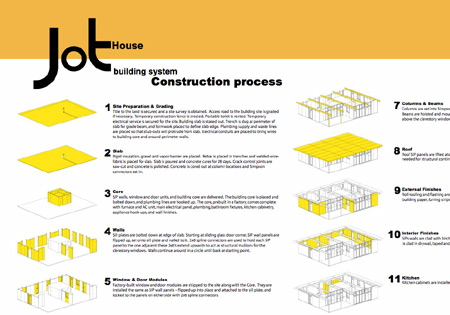

A couple weeks back, I reported on the JoT House. I've received a few more details about the JoT line of products from Jim Vinson.

The reported "as low as $100/sf" price was for a spartan artists loft. Their PDF states "the average cost is $180 per square foot" excluding design fees, site prep, and materials shipping.

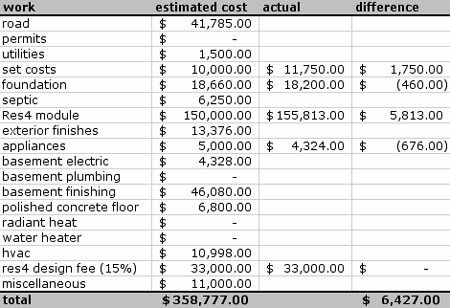

One of the great features of A Prefab Project is the detailed budget homeowner Chris keeps updating. As the project nears completion, it offers an accurate estimation of how much a prefab project from Res4 might cost you. Granted, your site work and other specifics might differ, but it's a good bunch of numbers to study.

I've pulled together the spreadsheet above showing the initial estimation of how much each piece of work would cost. I've then inputted numbers for the actual costs, based on what Chris has reported. They are doing an impressive job of sticking to their budget!

My only question: why does a prefab house have a 15% design fee? I emailed Resolution 4 on Aug. 7th and Aug. 11, but haven't heard back.

In today's issue of the Newark (Ohio) Advocate, a mortgage broker discusses the financing of mobile homes vs. manufactured homes vs. modular homes.

CubeMe found another company, producing small prefab outbuildings. We've covered  Modern Shed,

Modern Shed,  Modern Cabana and

Modern Cabana and  Ecospace, and now there is the

Ecospace, and now there is the  MetroCabin from

MetroCabin from  MetroShed:

MetroShed:

"The simple and sophisticated design allows it to exist easily in an urban setting, while the quiet strength and sturdy attitude are comfortable in a more rugged environment."

Update: fixed the picture (thanks to a commenter for pointing out the mistake)

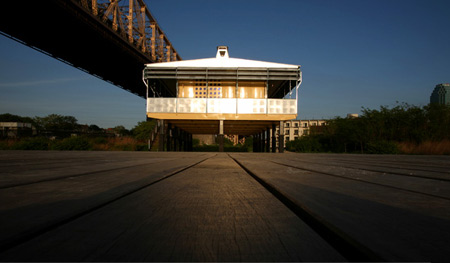

Jean Prouve's classic Maison Tropicale was sold last night at auction for $4.97 million, according to Bloomberg.com:

"'I just love Prouve,' said tanned hotelier Andre Balazs who bought the house and said he hasn't decided what he will do with it. Of one thing was he certain: 'It belongs back in the tropics.'"

The article added details on the house's history:

He sold one to American collector and former commodities trader Robert Rubin, who restored and donated his house to the Centre Pompidou in Paris. 'This price validates the other one,' said Rubin after the sale, speaking of the house he donated."

Jean Prouve's Maison Tropicale doesn't go on the auction block until next week. The vintage prefab stirred up a little more press this week. Luxist covered the home and linked an article in the Queens Tribune.

Treehugger brought a couple other treehouse companies to the table:

"If you want to live out your childhood fantasy of moving into your treehouse (and preferably seceding from the family), but a couple of planks slapped together with some rusty nails isn't going to cut it, you'll want to give the able carpenters of TreeHouse Workshop a ring."

Inhabitat's Prefab Friday shared thoughts and more good photos of Richard Rogers' Oxley Park Houses that Treehugger mentioned last week:

"The homes' most innovative feature is the 'EcoHat,' a roofing system that allows hot air to rise and consequently be reused to provide passive solar water heating, thereby mitigating the energy consumption of the house. Clever floorplans optimize natural lighting schemes, while prefab modules and flat-pack components reduce waste and energy..."

Inhabitat's Prefab Friday covered a prefab school project in progress by Jennifer Siegel's OMD:

We find this project particularly interesting as it is an addition to an existing structure, which provides not only site-specific but aesthetic and programmatic context."

The San Jose Mercury News ran an article about prefab and price:

About 1.4 million people in California live in manufactured homes, and the typical profile of an owner has become younger, more educated and more affluent...

...standard site-built homes cost about $250 a square foot whereas manufactured housing can be as low as $120 a square foot, a big savings for people used to paying top dollar in the Bay Area."

On Wednesday the New York Times published an article about the classic prefab Maison Tropicale up for auction:

"Tomorrow, the Maison Tropicale, a small aluminum-paneled house built in 1951 by Jean Prouvé, a French designer and the current court favorite of well-heeled contemporary art and design collectors internationally, is being opened to the public for preview in Long Island City. Christie's, the auction house, will offer it for sale on June 5. The presale estimate is $4 million to $6 million."

That article touched off a flurry of posts around the blogosphere about the house and its sale. Treehugger's Lloyd Alter shared his thoughts and linked to an earlier article all about the home:

"One of the most remarkable experiments in prefabrication was Jean Prouve's Tropical House, designed and built in France and airlifted in 1951 to be assembled in Brazzaville, now the middle of a war zone....Treehugger...learned from him that the process [of] assembly and dissassembly is hard on the house and its fittings, so this may be one of the very few chances to see this masterpiece. Prouve is under-appreciated, his work in building and furniture design is brilliant."

Tropolism tried to visit the house and reported back:

"The Maison is plug-and-play: there was never any plumbing, and it is wired for electricity. It ships in six containers. Christie's is compiling a short list of potential bidders with substantial properties in Mustique, Antigua, the Hamptons — name your playground — who might like a 59-foot-by-32-foot-by-16-foot-tall folly/outdoor sculpture/guesthouse/vintage metal toy to park on the lawn, with a designer label attached."

Apartment Therapy mentioned the home. Erratica excerpted the NY Times article and some of the NY Times images. Prefab Update posted the same images.

The Christie's auction lot shared some more details on the home:

• all load bearing parts in bent steel sheets, all covering parts in bent aluminum sheets

• the interior steel floor covered with modern iroko and rubber boat decking (not designed by Jean Prouvé) replacing the original linoleum

• with two modern access stairs (not designed by Jean Prouvé) and with original connecting platform

The home's early use of factory-built parts jives with Jean Prouve's character, as discussed in this International Herald Tribune article from last year:

He studied under two of France's most gifted blacksmiths, Emile Robert and Szabo, both of whom produced 'art metalwork': wrought-iron grilles and doors in ornate floral shapes....Prouvé followed his father's design principles: 'Learn about the past; never plagiarize; always use the most up-to- date methods.'"

I just found a Yahoo! Group dedicated to sharing the thoughts and experiences of  LV Series homeowners. LV Series homeowner Gregg started the group in July of 2005:

LV Series homeowners. LV Series homeowner Gregg started the group in July of 2005:

The reason I am starting this group is because I have had a lot of questions during this process to which I could not find answers on the web -- the most notable example being the actual cost....I felt it would be a good idea to have a forum for people interested in the home to be able to ask around."

Foundation: +3300 Framing and roof: +5000 Heat, Plumbing, Elec: +1500 Interior Finish: +400

...It fell very close to Rocio's estimate, and I am in one of the most expensive areas of the country."

One user, having just finished his LV Home posted a full recap of construction costs, photos and thoughts on the project:

"Note that we did not encounter any big problems during construction. I will say that we were not pleased at all with the costs and do blame our contractor for a lot of the cost madness. But when we solicited bids more than one builder said, "kit or no kits, the cost per square foot will be the same." And that bore out to be true."

If you want to build an LV home, this is definitely a must-visit site.