I am on vacation all of this week, but will be returning September 1. Look for new posts then.

The Washington Post discussed MoMA's Home Delivery show earlier this week, leading with a quite provocative line:

The architect who masters prefabricated housing -- how to make homes that are well designed, mass-produced, affordable and easy to build -- may well go down in history as the Last Architect.

Got my attention, at least. The article continues with the prodding:

As a fascinating and important new Museum of Modern Art exhibition, "Home Delivery: Fabricating the Modern Dwelling," makes clear, they have mostly failed. But if anyone ever succeeds, perhaps the grand challenge of domestic architecture would be over -- time's up, pencils down.

The article makes many such observations and poses a few questions:

The paradox of the prefab dream, which began with proles in boxes, is that it lingers in the bourgeois craving for luxury goods and second houses.

And so does prefab turn out to be just another designer accessory, not so different from Louis Vuitton handbags or Prada shoes, industrial status symbols that are basically the same from unit to unit? Is it true once again that the blessings of modernism, supposedly a gift for the many, are really just a prize for the few?

Some specific thoughts on the homes in the show:

the ridiculously small confines of the Micro Compact House will [not] leave you with any desire to live there.

the System3 project ... is a compelling piece of architecture by any standard.... Stand in the System3 for a few moments, and you want to live here.

In summary:

"Home Delivery: Fabricating the Modern Dwelling" will leave you honestly conflicted, dubious about where history has brought the prefab dream. And more than ready to move into a prefab castle, just as soon as you can buy a nice plot of land and muster the down payment...

What do our readers think about The Posts's observations? Have most of prefab's early practitioners failed? Is prefab just a "prize for the few?"

While reading the full article, be sure to check out the accompanying slideshow.

From Materialicio.us, here's a useful tip for those interested in MoMA's Home Delivery exhibition:

I just went to see the show myself this past monday, and I put the best of the photos I took up on Flickr the next day. I tagged them and yesterday decided to see who else had visited and tagged their photos with “Home Delivery”. I was pleasantly surprised to see many other photos on Flickr. A great way to get a photo tour if you can’t make it to the show.

The link: Flickr Home Delivery search

Witold Rybczynski filed a slideshow report from MoMA's Home Delivery show. In his usually candid style, he gives his impressions of the show, inside and out:

Prefabricated houses have remained an elusive goal for architects, and the MoMA show is a stylish litany of second-place finishers, also-rans, if-onlys, and downright losers.

I'd dare to say that just being included in the MoMA show makes each of the featured projects a first-place, upright winner, but maybe that's just me. Anyway, back to Witold:

After considering some 500 firms, the museum chose younger, lesser-known architects, and the range of solutions demonstrates both a sense of enthusiasm and a variety of novel prefabrication technologies.

He shares his thoughts on the  BURST*008:

BURST*008:

The rather crudely built structure looks out of place here—or, I suspect, anywhere.

The  System3:

System3:

most people's idea of contemporary prefabrication: It's elegant, stylish, and rather austere.

Larry Sass's Instant House:

an ingenious and very complicated answer to the wrong question. ... The laser-cut decorative fretwork on the porch is nice, though.

The  m-ch:

m-ch:

Nothing revolutionary here, but a very nicely designed package.

(Though he suggests buying an Airstream trailer instead.)

And the  Cellophane House:

Cellophane House:

The design, fabrication, and construction are seamlessly integrated, and the various pieces are automatically ordered from the fabricator to suit the design as it is entered into the architect's computer. If there is a Next Big Idea in prefabrication, this may be it.

For the rest of Rybczynski's thoughts and some great photos, check out the whole slideshow at Slate.

The Christian Science Monitor took a look at modular homes last week, focusing on the green qualities:

This summer, two exhibitions of modular houses – at Chicago’s Museum of Science and Industry (MSI) and New York’s Museum of Modern Art (MoMA) – are putting a spotlight on how off-site building techniques can shrink the carbon footprint of a new house.

The article cites a number of reasons why building in the factory is a good idea:

- finish construction usually takes a few weeks, not months, saving energy by requiring fewer trips to the job site by construction workers

- by building indoors, workers can also more easily make sure that energy-saving features like insulation are carefully and properly installed for maximum effectiveness

- individual home-building companies may not have the resources to keep current on the latest "high-performance building" techniques ... but modular homes can have state-of-the-art environmental design built into them at the factory

The companies mentioned in the article:

-

KieranTimberlake Associates

KieranTimberlake Associates

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

-

HOM Escape in Style

HOM Escape in Style

- Envision Prefab

- Cardinal Homes

Read the complete article for details.

I was away this weekend, so here's last week's prefab news a bit late. (Posted Tuesday, but dated Saturday in line with our "This week" series.)

Inhabitat's Prefab Friday looked at  Marmol Radziner's new Rincon 5:

Marmol Radziner's new Rincon 5:

The unit was recently showcased in a Los Angeles event that explored its possibilities as a guest house, yoga studio, and home office. Want to make your new guest bedroom a Rincon 5? The basic unit costs $223,000 to be built, delivered and installed, plus the price of whichever upgrades you think your guests will appreciate most.

Materialicio.us noted that the price of the OMD showhouse in Venice has been reduced. The home (without the lot) was originally listed at $295,000, and then reduced to $259,000. Now:

reduced to $175,000

This year's West Coast Green features a new Showhouse built of containers:

At its core, the 1,700 sqft two-story home will be made of reused shipping containers, which will make construction, in any environment, sustainable, fast, and safe.

Being built right on the tradeshow floor, the home will open to a series of outdoor living spaces and decks, showcasing a dramatic outdoor kitchen ... and a stunning garden of native and naturalized plants and mature olive trees.

The stats:

- 1,700 sf

- 2 bedrooms

- 2 bathrooms

- 2 stories

Jetson Green likes it:

It's a 1700 sf container home, but you probably can't tell just by looking. Sustainability will be number one, with GreenPoint and LEED certification in the plans. Plus, it seems that ecofabulous will be doing the interior design work, so the home, you can believe, will be modish, posh, and green.

Until August 18, you have the opportunity to come up with a name:

Name the Showhouse!

We’ll pick the top submissions, and post them for everyone to vote on.

Whatever name gets the most votes, wins!

We will announce the winning name on September 1st

This year's West Coast Green building conference and expo comes to San Jose, California at the end of September:

You’ll find over 380 exhibitors showcasing the latest in resource-efficiency among a stunning array of green and healthy building products. Over 100 experts and visionary leaders will be presenting their latest developments, insights, and inspiration at the expanding frontiers of the field.

While there aren't many prefab-specific agenda items worth noting, the conference's educational agenda includes a presentation by  Michelle Kaufmann on "The Art of Mass Customization".

Michelle Kaufmann on "The Art of Mass Customization".

The long list of presenters includes Allison Arieff, former editor of Dwell magazine, and even Al Gore.

The show features a Showhouse built of containers; we'll cover that tomorrow.

Michelle Kaufmann

Michelle Kaufmann

MSNBC's Virtual Lifestyles visited the  mkSolaire in Chicago and filed the above video report. Look for:

mkSolaire in Chicago and filed the above video report. Look for:

- explanations of the home's green features

- an interview with Michelle Kaufmann

- a quick montage of the home's assembly

- various views inside and out

- a talking plant!

The price mentioned for the home: $450,000.

The Chicago Tribune visited  Michelle Kaufmann's

Michelle Kaufmann's  mkSolaire exhibit last week:

mkSolaire exhibit last week:

everything in and about the 2,500-square-foot home on exhibit just outside of the Museum of Science and Industry in Chicago has been designed to show the public how easy it can be to incorporate environmental sustainability into their own abodes.

Michelle Kaufmann commented on her hopes for the exhibit:

"We tried to look for ideas in every choice that we make in our homes ... hoping that everyone who goes through it will be inspired to make some change on some level.... Some people will walk away and want to do an entire new home, or some people will think when they go for their towels next and go for organic linens."

Some of the many features of the home:

- half the energy of traditional homes

- a third of the water of traditional homes

- water from the bathroom sink is diverted to the toilet

- a bicycle in the children's bedroom must be pedaled for 30 minutes to charge a battery to power video games

Interesting:

Visitors receive a resource guide that tells about the function of each feature, how they're assembled and where they can be purchased.

e-OCULUS, the blog for the New York chapter of the American Institute of Architects, criticized MoMA's Home Delivery exhibition:

Even though digital fabrication is interesting, I believe there is so much more that goes into prefab housing today than mass production. The eras represented in the exhibition are coming together to create contemporary prefabrication that exists out of necessity, invention, experimentation, as well as digital design. If MoMA had chosen to include examples of buildings that are built, or at least in planning phases ... the exhibition would have more relevance and urgency needed to put the many current prefab ideas into production.

DVICE, a blog from SciFi.com, shared some favorites from the show.

Inhabitat had a double Prefab Friday. First, they linked to ScribeMedia's video from MoMA, seen above:

Chock full of interviews with architects and led by Chief Curator of Architecture & Design Barry Bergdoll, it’s a must-see for anyone interested in a current survey of the potential of prefabricated housing.

Second, they covered the Glenburn House:

...it would be easy to miss this deceptively simple, yet elegant house nestled into the surrounding countryside. But once you have reached this beautiful abode designed by Sean Godsell it’s hard to forget it.

A useful link: Sean Godsell's site.

Jetson Green provided an update on the GreenMobile® from Mississippi State University:

At present, the university ... is trying to finalize agreements with industrial partners.

The Marmol Radziner blog has lots of news about their recently completed Palms House.

The home's specs:

- 2,800 sf

- 3 bedrooms

- 2.5 bathrooms

- living/dining, kitchen, office

KTLA, a TV station out of LA, visited the house last week and filed a number of video reports (hosted by a slightly overbearing correspondent). One is seen above. A couple others:

- the first floor (3:11)

- the second floor (2:24)

- the exterior (3:02)

Back in June (sorry we missed this!), the home was featured on Planet Green Channel's Renovation Nation:

Our episode highlights the green features of prefab building and follows the Palms House as it traveled through our factory.

Be on the lookout for a re-run in your area.

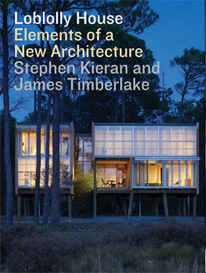

Another new book:  KieranTimberlake Associates principles Stephen Kieran and James Timberlake profile the design and construction of their

KieranTimberlake Associates principles Stephen Kieran and James Timberlake profile the design and construction of their  Loblolly House in a volume released in June:

Loblolly House in a volume released in June:

Through the use of state-of-the-art building information modeling (BIM), the architects were able to streamline the design-build process. Thousands of parts were collapsed and integrated into a few dozen panels and blocks that slid into an aluminum frame set on wooden pylons. Consisting of 70 percent prefabricated components, the kit-of-parts house was assembled (mostly with a wrench) and lifted into place on-site in less than six weeks.

The Dwell blog approves:

... handsomely documents the entire design-build process of the Loblolly House.... I dare say this book should be required reading for all architects, contractors, and developers.

Also worth noting:

The book includes a DVD of the film "A House in the Trees" by producers Rick Deppe and Kathleen Blake, a real-time documentary of the design, fabrication, and assembly of Loblolly House.

The list price of $40.00 is reduced to $26.40 at Amazon.

See also: our page of prefab books.

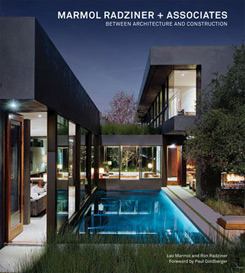

Marmol Radziner + Associates released a new monograph last month. Written by firm principles Leo Marmol and Ron Radziner, the book also features a foreword by Paul Goldberger, architecture critic for The New Yorker. From publisher Princeton Architectural Press:

Marmol Radziner + Associates released a new monograph last month. Written by firm principles Leo Marmol and Ron Radziner, the book also features a foreword by Paul Goldberger, architecture critic for The New Yorker. From publisher Princeton Architectural Press:

If you design some of the most stylish and beautiful modern houses in the Los Angeles area, including many for celebrity clients, how do you ensure that the projects are built to the standards you, and your patrons, demand? If you're the highly sought-after firm of Marmol Radziner + Associates, you do what an increasing number of practices are doing: become your own contractor, building your projects with the same rigor and beauty with which they were designed, and, in the process, remake your firm into one of the most visible and successful design-build firms in the country....

[The book] explains in detail how this pioneering design-build firm — one of the few led by architects — has managed to integrate building–installation, construction, and fabrication into one seamless design process.

Keep an eye on the Marmol Radziner blog for announcements of book signings.

Listed at $40.00, the book is on sale at Amazon for $26.40.

See also: our page of prefab books.

Very interesting -- though apparently not headed to the US. From an article in the Wall Street Journal:

Best known for its top-selling cars like the Prius and Corolla, Toyota is looking to apply its ecofriendly image and technical know-how to help boost sales of its small and little-known prefabricated-housing division.

Unbeknownst to most of us, Toyota prefabs have been around for awhile:

Since 1975, Toyota has been building steel-frame houses designed to withstand earthquakes and typhoons and keep out burglars.

The tie-in with Toyota's vehicles is certainly interesting:

Toyota's aspirations as a home builder are also gaining new importance with the planned launch by 2010 of its plug-in vehicles, gas-electric hybrid cars with powerful lithium-ion batteries that drivers will need to recharge at home. The car maker is testing an electricity-monitoring system in its homes that would charge the vehicle during off-peak hours to keep utility bills low, while the car's battery can serve as an electrical backup, powering the home during blackouts.

I can't help but quote this imagery:

At the Kasugai Housing Works in central Japan, one of Toyota's three prefab-housing factories, an assembly line of robots, conveyor belts and helmeted workers produced a steady flow of rectangular steel-framed cubicles finished with staircases, kitchen cupboards, bathtubs and toilets.

The timeline sounds right:

Most Toyota homes are made from six or more of these large cubicles, which are assembled -- like Legos -- on the building site. From its start on the factory floor to its final completion on site, a Toyota home can be built in 45 days, less than half the time it takes for contractors to build a typical wooden-frame home, Toyota says.

Alas:

Other than what it called a one-time "experiment" building a development of 50 homes near its truck plant in San Antonio in 2006, Toyota says it has no ambitious plans to build homes outside Japan.

The company's past sales leave much room for expansion, within Japan and abroad:

- 5,000 units in 2006

- 4,600 units in 2007

I couldn't find an official Toyota Homes Website, just this little tidbit from Toyota's homepage.

Read the whole article for some housing issues that are specific to Japan.

Here's a round-up of other recent coverage on Zamore Homes.

Inc.com included Zamore's pitch:

...I sell detailed designs, plus a list of materials that customers can have shipped from nearby facilities, including Trussway for building supplies and Ikea for cabinets. I was the general contractor for the first three homes, which will be on sale in Houston this summer. Eventually I'll charge $3,000 to $7,000 for the list and drawings.

materialicio.us concludes:

Pretty damn cool, if you ask me…

Dwell's blog wonders:

But is Zamore’s method the most sustainable? Michelle Kaufman, a leader in the prefab industry, argues that, in her experience, it’s more energy efficient to build offsite.

Apartment Therapy Los Angeles remarks:

Now if they could only reduce the price of the land itself here, we'd be living in pre-fab comforts!

Jetson Green covered the homes earlier this month.

A busy week!

Inhabitat's Prefab Friday enjoyed Method Homes' cabin:

we’re happy to report that Method Home’s modern wood wonder has blossomed into a beautiful home.

Inhabitat also covered HOM:

Simple, purposeful, ecological and crafted, HOM houses are meant as secondary residences; a HOM away from home to which busy urbanites can escape in style.

Jetson Green wrote about a container home in San Francisco, designed by Leger Wanaselja Architecture:

It's a simple design that shows what [is] possible with innovative home construction.

Visit Jetson Green for the full post and a bunch of photos of the home. The previous day, Preston previewed the West Coast Green showhome:

It's a 1700 sf container home, but you probably can't tell just by looking.

We'll cover West Coast Green and the showhome in more detail soon.

And a little more news on MoMA's Home Delivery show. New York's The Villager discussed the show:

“Home Delivery" ... is a coup for quality. It’s also a tour of prefab past, a spiffy toy store of drawings, models and actual toys from the century-plus history of industrialized home construction.

Business Week reran a short article from Architectural Record on the show:

One of New York's most exciting cultural venues this summer is a vacant lot in Midtown Manhattan....

Moco Loco ran a series of posts on their favorite three homes in the show. They introduced the show Monday. On Tuesday, they covered the  System3 house:

System3 house:

Inside, its austere bearing gives way to a more luxurious simplicity...

Wednesday's post featured an interview with Cellophane House designer James Timberlake:

What will happen to this particular home on October 21? We are working on this concurrently with the show. We have discussed the possibility of auctioning the house.

Thursday's post looked at  BURST*:

BURST*:

But marveling at the architecture is not the point of BURST*. Ultimately, the structure puts the emphasis on nature: The house’s rear elevation unfurls in a cascade of bleacher-style seating, all the better to sit and enjoy the view—out.

Last week, The Houston Chronicle took an in-depth look at Zamore Homes.

When Sears started selling kit houses by mail in 1908, the company promised that a man of average abilities could assemble any of the models in the catalog — from a small gabled cottage to a roomy Dutch colonial....

Exactly one century later, Houston architect Brett Zamore is bringing kit homes back.

Zamore assumes that the average man or woman of today has neither the desire nor the ability to assemble a home. That's why Zamore Homes will gather the materials, coordinate delivery and manage the construction process....

Some homes are local:

Zamore is just finishing construction on three kit houses in Houston's West End, on Center near Thompson.

Some not:

Mississippi native Karen Parker ... mother of six lost her Biloxi home to Hurricane Katrina ... selected Zamore's design and finally moved into her 1,400-square-feet home this past January.

The article provides a good working definition of "prefab":

In the strictest terms, prefabricated homes are built and assembled in a factory and then shipped to the property. In a larger sense, the term could also apply to homes with prefabricated parts that are assembled on site.

Zamore Homes models fall into the latter category.

In all, there are seven designs, in sizes that reach 2,200 square feet. But the KIT05 can grow as large as the homeowner wants.

Here's the models and specs from the Zamore Homes site:

- KIT00: 400 sf, 1 bedroom ("little casita")

- KIT01: 992 sf, 2 bedrooms

- KIT02: 1,250 sf, 2 bedrooms

- KIT03: 2,000 sf, 2 bedrooms

- KIT04: 2,200 sf, 3 bedrooms

- KIT05: varies

- KIT06: 1,300 sf, 3 bedrooms

- KIT500: 504 sf, 1 bedroom

Compared to local costs in the Houston area:

... new construction going for $130 to $170 per square foot.

The pricing sounds quite competitive:

Zamore's kit homes cost between $110 and $150 per square foot, which includes hard and soft construction costs. [information on hard vs. soft construction costs]

Here's our quick comparison to other kit homes:

| Company | Models | Materials supplied | Advises |

|---|---|---|---|

Rocio Romero Rocio Romero |  LV Series LV Series | only the walls and roof framing | windows, finishes and other materials |

kitHAUS kitHAUS |  k3 k3 | everything except interior fixtures (plumbing, lighting) | None |

Jeriko House Jeriko House |  Jeriko House Jeriko House | all finishes | None |

The materials and finishes page on the Zamore Homes site is worth a look.

Read the full article for more details.