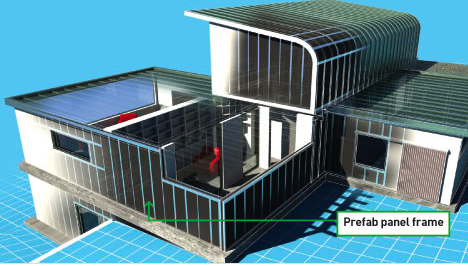

Popular Science recently featured a project using a new type of prefab panel frame by  kama Energy Efficient Building Systems.

kama Energy Efficient Building Systems.

These aren't your conventional structural insulating panels. Instead of foam and strand board, Kama...custom-makes the rigid panels out of light-gauge metal studs and a special type of expanded polystyrene called Neopor that's non-toxic, fully recyclable and blended with graphite to lock out heat, moisture and mold.

According to John B. Carnett, the Popular Science staff photographer who is building the house:

They cost me about 5 percent less than a stick frame would have, but they're 60 percent more energy-efficient and can cut heating and cooling bills in half.

The price listed in his specs for the prefab panel box installation is $7.04 per sf.

Carnett claims to be "the first in the U.S to incorporate Kama's new panels."

House details:

Follow progress via his blog.

Hat tip: Jetson Green on July 21, 2009.

Yankee Barn Homes in New Hampshire designs and builds custom post & beam homes nationwide using prefabricated elements.

Yankee Barn Homes in New Hampshire designs and builds custom post & beam homes nationwide using prefabricated elements.

We ... construct the wood framed True Wall, and True Roof panels, along with specialty millwork, in the protected, controlled environment of our workshop. We build everything that is practical in our shop, then pack the Yankee Barn for shipment to the site.

The Yankee Barn is raised on site and enclosed usually in twelve to seventeen days depending on the project size.

...

Our prefabricated approach to building allows our customers to design and build a custom home with all the latest energy efficient options and still manage to save money by shortening the construction time on their site.

More about the company:

- virtual tours

- photos

- NH Chronicle video (5:51)

- 100's of plans

- model home information

Worth a look: Why they use True Panels instead of SIPs.

While researching yesterday's post, we found some interesting information about  LionForce Building Systems and their construction process. According to their newly launched website:

LionForce Building Systems and their construction process. According to their newly launched website:

We use a proprietary wall and roof panel system that incorporates Expanded Polystyrene integrally molded to fit a special metal stud shape.

...

The panel system used for the shell (walls and roof) of the home are manufactured offsite based on engineered drawings...panels are delivered similar to a “flat-pack” product, are easily handled without hoisting equipment

The cost for the shell system is "about 5% more than a conventional stick-framed shell" and a standard home (1,600 sf) takes about 120 days to build.

In addition to their "green" focus, the company emphasizes their use of technology:

At the core of the ecoLiving platform is Building Information Modeling, or BIM. BIM software is revolutionizing all construction related industries because it the first parametric construction modeling and documenting software.

Something to watch for: LionForce will be launching an interactive home "configurator" this summer, in which

decisions are guided by our real-time display of selections indicating price, energy efficiency, LEED rating, and operating cost.

The Contemporist recently covered a two-family prefab in Austin, TX.

According to the architect's website:

The house is constructed of a modular steel frame. The frame is infilled with prefab thermasteel panels to minimize construction on-site waste. The structural frame is exposed, showing the construction process and articulating the house’s facades. The repetitive modular method, as well as the prefabrication allowed for greater efficiency during construction.

Check out:

- pictures ... though the Contemporist post has a nice selection that loads faster

- virtual tour

- Chinese magazine article in Vision May 2007 (PDF)

We also found a video (2:00) showing some of the construction details.

The February 2009 issue of Dwell Magazine featured a concrete prefab in Switzerland by architect Felix Oesch.

it took nine months to build the house using a prefabricated panel system

...

Each panel is made up of two outer layers of 2.4-inch-thick concrete, which act as the bread of the sandwich. Inside there’s a core layer of concrete as well as seven inches of insulation. This means the panels, which arrived onsite with all the holes cut for the fixtures and fittings, are relatively light and easy to maneuver. Subsequently, construction was a question of fitting them all together like pieces of Lego.

Read the entire article and view a slideshow containing 11 pictures of the home.

Hat tips: StyleCrave on March 17, 2009 via materialicious on March 11, 2009.

The goal of prefab is clear:

For more than a century, architects and builders have strived toward a prefabricated, industrialized house, one made in a factory so that economies of scale would be realized and the product would be affordable to all home buyers.

It's worth remembering that the current "stick built" process was itself an important innovation, "prefabricating" the basic components:

Until the 1830s, most houses in America were built with post and beam framing. All the pieces were hand-hewn and held in place with complex joinery, and home building was a time-consuming, costly process. Around then, however, steam-driven saws that could produce large quantities of accurately sized building lumber and machines that made huge quantities of iron nails began to appear in the larger cities.

An enterprising Chicago building contractor, George Washington Snow, saw the potential for these new products to revolutionize the building industry. He devised a method of framing that was much faster and far less costly.

One step forward in the meantime: panels (6% of homes built in the US in 2007).

the 2-by-4 stud walls sometimes are assembled in factories and hauled to a job site, an approach called panelizing.

A bigger step: modular (3% of homes built in the US in 2007).

a method of building in a factory an entire conventional wood-framed house in sections, loading each one onto a flatbed trailer, trucking it to a job site and then setting it in place with a crane.

Read the whole article for a few details on pros, cons, and possible futures.