Copeland Casati, founder of  Green Modern Kits, recently posted that she would be holding an Open House at her

Green Modern Kits, recently posted that she would be holding an Open House at her  casa ti Modern Net Zero Prefab.

casa ti Modern Net Zero Prefab.

The green building architect of the casa ti, David Day of David Day Design, will be available on site. Our fabulous contractor, Ron Bernaldo, will also be there so you can ask him [all] your building questions.

We recently received an email from a company called  Shelter-Kit in Tilton, NH.

Shelter-Kit in Tilton, NH.

According to their site:

Shelter-Kit® buildings include all of the materials required to construct a weather tight shell on your foundation: hardware, fasteners, framing, sheathing, floors, roofing, flashing, drip edge and trim.

All kits, except the Barn-House include a standard window & door package. All materials are hand selected, carefully cut to precise dimensions, labeled, and packaged in easily identifiable bundles that two people can carry.

Worth noting:

In the past 39 years, over 85% of our kits have been built by people with no prior building experience.

Shelter-Kit offers a variety of buildings and styles:

| Model | Price | Size | BR | Assembly Time |

|---|---|---|---|---|

Cape Style Barn-Houses Cape Style Barn-Houses |

$26,345+ | 875-2,500 sf | 1-5 | 10+ days |

Green Homes Green Homes |

varies | 875-2,500 sf | 1-5 | 10+ days |

Post & Beam Lofthouses Post & Beam Lofthouses |

$17,185+ | 415-1,565 sf | 2 | ~7 days |

Unit One Unit One |

$9,975+ | 144-1,500 sf | 1 | 3-4 days |

Also check out their kits for Barns, Garages & Workshops.

They are currently advertising:

Shorter lead times and special pricing are available for kits without major design modifications, for delivery by October 31, 2009.

The  casa ti prototype by

casa ti prototype by  Green Modern Kits has been covered in the news recently, according to a post by Copeland Casati:

Green Modern Kits has been covered in the news recently, according to a post by Copeland Casati:

NBC12 in Richmond, Virginia on August 4, 2009 includes a video (2:03)

C-ville Abode in Charlottesville mentions the house in their Green Scene section dated August 4-10, 2009

LamiDesign (La Vardera Milano) recently posted pictures of a Plat House in Texas built by one of their customers.

LamiDesign (La Vardera Milano) recently posted pictures of a Plat House in Texas built by one of their customers.

Check out the post for 16 more pictures.

FKDA Architects designs and builds micro-homes in the UK.

FKDA Architects designs and builds micro-homes in the UK.

They currently offer two models they call "sheds":

According to their site:

The shed could be entirely prefabricated in a factory and delivered to site

...

Alternatively, the components can be delivered and the shed assembled on site, with each being small and light enough for one or two people to manhandle, eliminating the need for a crane.

...

The total process typically takes around 18 weeks.

They are also working on a Zero Carbon modular house they are calling eco-home. We will post more information when it becomes available.

Hat tip: Inhabitat on June 16, 2009 via Design Boom on June 15, 2009.

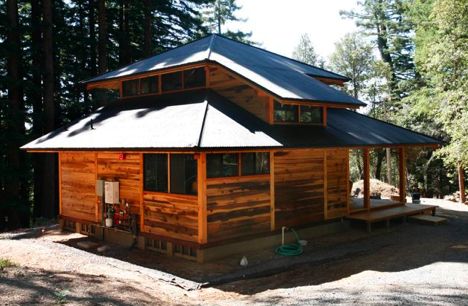

Live Edge in West Oakland, CA has an interesting source of wood:

Live Edge in West Oakland, CA has an interesting source of wood:

LE uses urban trees which are removed for many reasons: disease, storm damage, danger of falling, or to clear the way for a construction project. We regularly accept usable raw logs from local arborists and salvage some of these trees.

The company builds furniture and prefab houses.

The building process is based on an 8ft. modular plan...The kit is comprised of posts, beams, floor panels, wall panels, doors, roof and ceiling components. It is a finite set of parts which can be arranged in an infinite number of ways. Live Edge produces all the parts for a kit home in our shop, adapted to each design, to be assembled on site.

Check out their picture gallery.

Hat tips: Apartment Therapy on March 26, 2009 and Jetson Green on March 27, 2009.

We received an email a while back from Copeland Casati, founder of  Green Modern Kits.

Some background:

Green Modern Kits.

Some background:

The housing crisis and concern over our earth propelled her to gather green building energy-system and design partners to help other eco-conscious individuals achieve their green goals. She wants to help other people like herself find affordable, green housing solutions.

The company currently has two models available.

Both kits are bare bones: you get beautiful design and structure (SIPs exterior walls & roof, and design documents) and you will need to finish the house with a local contractor.

Model information:

- R1 floorplan first floor (PDF)

- R1 floorplan second floor (PDF)

- R1 floorplan with addition (PDF)

- R1 floorplan with garage (PDF)

Also check out:

- Copeland Casati's blog

- 60 pictures of casa ti prototype under construction

-

Green Cottage Kits

Green Cottage Kits

-

Green Cabin Kits

Green Cabin Kits

Last week, The Houston Chronicle took an in-depth look at Zamore Homes.

When Sears started selling kit houses by mail in 1908, the company promised that a man of average abilities could assemble any of the models in the catalog — from a small gabled cottage to a roomy Dutch colonial....

Exactly one century later, Houston architect Brett Zamore is bringing kit homes back.

Zamore assumes that the average man or woman of today has neither the desire nor the ability to assemble a home. That's why Zamore Homes will gather the materials, coordinate delivery and manage the construction process....

Some homes are local:

Zamore is just finishing construction on three kit houses in Houston's West End, on Center near Thompson.

Some not:

Mississippi native Karen Parker ... mother of six lost her Biloxi home to Hurricane Katrina ... selected Zamore's design and finally moved into her 1,400-square-feet home this past January.

The article provides a good working definition of "prefab":

In the strictest terms, prefabricated homes are built and assembled in a factory and then shipped to the property. In a larger sense, the term could also apply to homes with prefabricated parts that are assembled on site.

Zamore Homes models fall into the latter category.

In all, there are seven designs, in sizes that reach 2,200 square feet. But the KIT05 can grow as large as the homeowner wants.

Here's the models and specs from the Zamore Homes site:

- KIT00: 400 sf, 1 bedroom ("little casita")

- KIT01: 992 sf, 2 bedrooms

- KIT02: 1,250 sf, 2 bedrooms

- KIT03: 2,000 sf, 2 bedrooms

- KIT04: 2,200 sf, 3 bedrooms

- KIT05: varies

- KIT06: 1,300 sf, 3 bedrooms

- KIT500: 504 sf, 1 bedroom

Compared to local costs in the Houston area:

... new construction going for $130 to $170 per square foot.

The pricing sounds quite competitive:

Zamore's kit homes cost between $110 and $150 per square foot, which includes hard and soft construction costs. [information on hard vs. soft construction costs]

Here's our quick comparison to other kit homes:

| Company | Models | Materials supplied | Advises |

|---|---|---|---|

Rocio Romero Rocio Romero |  LV Series LV Series | only the walls and roof framing | windows, finishes and other materials |

kitHAUS kitHAUS |  k3 k3 | everything except interior fixtures (plumbing, lighting) | None |

Jeriko House Jeriko House |  Jeriko House Jeriko House | all finishes | None |

The materials and finishes page on the Zamore Homes site is worth a look.

Read the full article for more details.

Via Curbed LA:

LivingHomes is partnering with Philadelphia-based architecture firm KieranTimberlake Associates on an “expandable” single-family (pictured above) prefab green homes that can grow from 900 square feet to 2,230 square feet. All parts of the home are made in a factory--and owners can essentially order more parts of their home as their family grows... Additionally, the home will be priced at $215 a square foot, but as the country catches on to the expandable home, costs are expected to drop to $155 a home.

The post quotes Steve Glenn of  LivingHomes:

LivingHomes:

As you marry, have kids, add in-laws to the household, etc., you’re either moving a lot or constantly renovating, which is time-consuming, expensive, stressful, and very wasteful from a resource perspective.... LivingHomes by KieranTimberlake introduce an important new capability to homes – the ability to efficiently and cost-effectively adapt to people’s changing lifestyle living needs.

Treehugger adds:

As a cured architect and developer, I could only dream of what the result might be if one mixed the talents and innovations of architects like Kieran Timberlake with a business visionary like Steve Glenn and set them to produce small, efficient projects that don't need a Silicon Valley multimillionaire's income to own.

That's worth some research, and we'll share the details soon.

We mentioned the  Jeriko House last year. Here are some construction details:

Jeriko House last year. Here are some construction details:

Jeriko House is based on a sophisticated high-tech 'kit-of-parts' building system providing high strength and incredible ease of assembly.... The heart of this system is its unique high-performance aluminum framing derived from the 'T-slot' framing commonly used in industrial automation applications. Made from aerospace-grade aluminum formed into precision shaped 'profiles' offering the approximate strength of steel with a great savings in weight, the Jeriko House frame structure is resilient, weatherproof, rustproof, and pest-proof....Using special modular connectors, the Jeriko House frame is assembled in a classic post & beam structure. Houses as small as 240 square feet and larger than 6,000 square feet can be built. These unit shapes can be combined in a variety of ways....

In addition to custom options, the Web site shows four sample floorplans:

As of July 2007, three projects were underway:

...now under construction in Louisiana: a 4320-sq-ft Lakefront home; a 5500-sq-ft luxury home in Mandeville; and a 250-sq-ft garden retreat in Metairie...

On the heels of the port-a-bach comes news of the iPad, another prefab "bach" (see note below) from New Zealand:

The iPAD is a true kitset bach designed to covers a range of options; it could be a one bedroom holiday home, secondary dwelling, granny flat, office, studio or resort unit to name but a few.It can be grouped as a series of pavilions to form larger accommodation if required....

Of particular note is that the iPAD can be either manufactured off-site and easily transported to its final destination, or shipped as a kitset and erected on site by a licensed contractor.

TreeHugger has some thoughts and also mentions the earlier Bachkit.

Bach = "small structures like beach huts or small holiday homes" (from Shedworking)

(Hat tip: Materialicio.us)

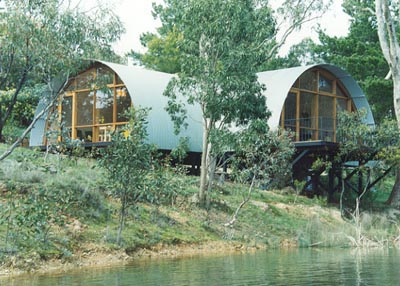

RAL Homes is a company in Victoria, Australia producing home kits that resemble Quonset Huts. The

RAL Homes is a company in Victoria, Australia producing home kits that resemble Quonset Huts. The  RAL Home kits can be combined in a number of formations, and even added on to your existing home. The kits consist of a series of pre-framed panels which join together to form an arch.

RAL Home kits can be combined in a number of formations, and even added on to your existing home. The kits consist of a series of pre-framed panels which join together to form an arch.

"The components arrive on site, complete with hardware and including an illustrated Assembly Manual. Two workers with a basic knowledge of Carpentry skills and standard tools simply bolt panels together. The external Colorbond corrugated steel roofing and leaf-free guttering system make RAL Homes virtually maintenance free."

Rocio Romero was not present at CA Boom 4, but she and her team run a serious prefab operation. I spoke with Donna Rosanswank, Sales Manager, on the phone last week. 35

Rocio Romero was not present at CA Boom 4, but she and her team run a serious prefab operation. I spoke with Donna Rosanswank, Sales Manager, on the phone last week. 35  LV Series homes have been completed from the 100 LV Series kits sold since operations began in 2003. Many homes are built from more than one kit, and some projects have been delayed. Sales are doubling every year and they will expand into Canada by early next year.

LV Series homes have been completed from the 100 LV Series kits sold since operations began in 2003. Many homes are built from more than one kit, and some projects have been delayed. Sales are doubling every year and they will expand into Canada by early next year.

The LV series includes:

design:

• standard or customized floorplan (extra $ for custom design time)

• full set of construction documents (exceeds UBC and IRC requirements)

• list of materials, product specifications, and a construction schedule to help your local contractor realize your project

• a binder listing all of the suppliers used to build the original show home; this will help homeowners source materials that are not included in the kit

materials shipped with the kit:

• exterior wall panels

• structural components for floor and roof

• exterior siding

materials that are NOT included:

• interior framing materials

• interior finishes

• windows and doors

• fixtures (plumbing and lighting)

• roofing

The home kits include so few finish materials because "Rocio wanted to be able to fit the whole kit in one flatbed delivery," and to allow customers flexibility in the final product.

Three prefab companies that exhibited at CA Boom in 2006 didn't return this year. Why not? Let's start with  Taalman Koch.

Taalman Koch.

I spoke with Alan Koch yesterday about their aluminum and glass iT House:

Why didn't you return to CA Boom this year?

"It was a lot of work last year and we didn't feel like it was our audience. Our house is a little more fussy than some. It requires a big leap of faith to live in an all glass house. It's not cheaper faster; it's a lifestyle choice. [Our audience is] a very niche market. It's not the general population, not even people interested in modern homes. It's about getting in touch with something - themselves or the landscape. It's a tool for reaching a new state."

I noticed you removed all information about standard models from your website, what is the plan there?

"We're not sure about the models and are reevaluating currently. Because of the way we were trying to offer the building before, we weren't really sure what it was. There was something about the way that it was presented that implied anything was changeable - that someone could build a 5,000sf iT House. It doesn't translate to that scale."

You and your wife have a variety of work in your portfolio, why prefab?

"We explore all kinds of things, stumble upon interesting things and do something with them. It's not exciting to just talk about problems architects are interested in. Prefab is not totally in the realm of the architect. We like and are satisfied by the process of figuring out prefab."

What do you think is one advantage of prefab?

"All the story that's published right now is 'modern and cheaper.' It is cheaper in a way; none of our clients could afford the design time we've poured into the house. Everyone who does buy an iT House gets the benefit of the hours of design time...for a cheaper price."

I understand that you are building an iT House prototype in the California desert. How is that going?

"We are almost finished with the model, and have done a lot of the work ourselves. We can't do everything, like roofing. But we did things like the frame. It was very simple to put together: 4 guys, 1 day, no skills and we had no problem setting up the whole frame. If you show the drawings to a contractor, they get worried because it's not something they know, so they tend to overcharge."

To find out more about the iT House prototype, check out the iT House blog.

Read more about the iT House in the blogs: Treehugger discusses the iTHouse's green properties. Inhabitat shares details about another iT House built in Orange County, CA.

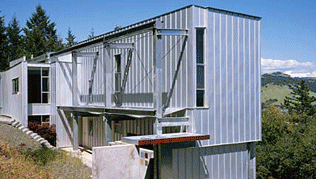

Sander Architect's

Sander Architect's  Hybrid House is more philosophy than product. Coming to CA Boom 4 with what they call "part prefab, all custom™", Sander Architects designs custom homes using prefab techniques and products. Every Hybrid House comes with a prefab structural steel frame; some incorporate prefab wall and roof panels.

Hybrid House is more philosophy than product. Coming to CA Boom 4 with what they call "part prefab, all custom™", Sander Architects designs custom homes using prefab techniques and products. Every Hybrid House comes with a prefab structural steel frame; some incorporate prefab wall and roof panels.

Catherine Hollis, wife of principal Whitney Sander, told me that Sander Architects thinks of architecture "as an artform." They use prefab elements to extend clients' budgets, but they see a rigid 100% prefab approach as limiting. Installation of finishes and fixtures takes place on site using traditional construction methods, and therefore with the traditional construction timeline.

Sander Architects has five Hybrid House homes under construction, ranging in size from 3,000 sf to a monstrous 8,000 sf home. Proving the benefits of their "part prefab, all custom" process, a 3,000sf home being built in Culver City, CA should come in at about $150/sf, much lower than some of the 100% prefab outfits at CA Boom.