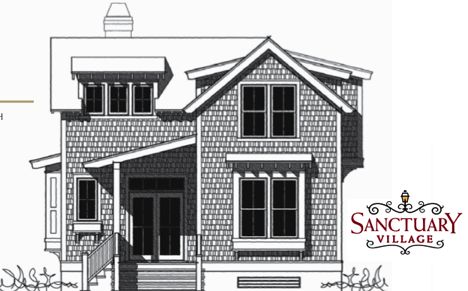

Haven Custom Homes recently issued a press release to announce completion of their first home at

Haven Custom Homes recently issued a press release to announce completion of their first home at  Sanctuary Communities in North Carolina.

Sanctuary Communities in North Carolina.

The home was delivered to the site ... nearly 80 percent complete.

...

The neighborhood is designed to reflect neighborhoods of America's past and be a walkable, mixed-use village when completed.

Also available in 2009:

| Model | Size | BR | Bath | |

|---|---|---|---|---|

Cowee Creek II Cowee Creek II |

1,002 sf | 1 | 2 | |

Cowee Creek I Cowee Creek I |

1,496 sf | 2 | 3 | |

The Windy Gap The Windy Gap |

1,343 sf | 2 | 3 | |

The Cullowhee The Cullowhee |

1,879 sf | 3 | 4 | |

The Redlands The Redlands |

2,598 sf | 3 | 4 | |

Hat tip: Building Systems Blog on March 24, 2009.

Read our earlier post for more details on the development, and the role of modular.

NY Daily news recently covered a prefab housing development in East New York.

Details:

-

designer:

Alexander Gorlin Architects

Alexander Gorlin Architects

-

builder:

Capsys Corp.

Capsys Corp.

- developer: Nehemiah Housing Development Fund

- price: $158,000 - $350,000

- plan: over 550 homes by 2013

The Nehemiah houses in the Spring Creek development are being assembled

in a Brooklyn Naval Yard factory as big as a football field

where construction workers

churn out more than 8,000 square-feet per week on a supersized assembly line for homes. Working in three separate areas, men build ceilings, flooring and wall frames. Cement trucks pour concrete floors while blast machinists drill holes for pipes and wiring. Then, the three components merge as the homes take shape. Beams are established, paint is applied, and toilets are installed.

After tying down any loose parts such as kitchen drawers and oven doors, the 20-by-40 units are shipped by extra-wide flatbed trucks to the East New York site.

On site, a 250-ton hydraulic truck crane lifts the units on top of each other to build the two-, three- and four-story homes.

Worth noting:

Founded in the mid-1980s by powerful local preachers as a means to rebuild East New York, the Nehemiah Housing Development Fund Co. is the real estate arm of East Brooklyn Congregations. In 20 years, they built and sold more than 3,000 homes with a foreclosure rate of less than 1%.

Read the entire article for more information, and see pictures of the units on the Capsys website.

Building Systems blog reported back in November:

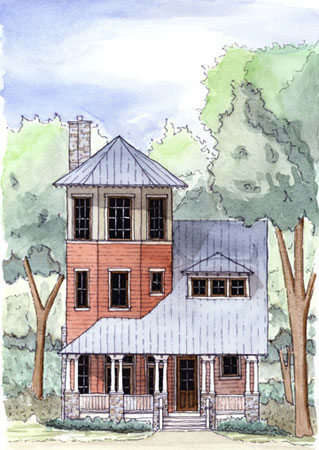

Carl Krave, president of Pocket Neighborhoods, a builder and developer in the Tampa Bay, FL ... recently won the coveted Aurora Award for his Glencairn Cottages project.

These green and energy-efficient model homes, which are built off site by Nationwide Custom Homes (Martinsville, VA), replicate the old, historic homes seen in Key West, FL, and Charleston, SC. The project won the award for the best development on less than 100 acres

Worth a listen: their podcast about Krave's strategy.

Worth browsing: Glencairn Cottages

Builder:  Nationwide Custom Homes

Nationwide Custom Homes

Here's an interesting modular development that was announced last month:

Haven Custom Homes ... and Sanctuary Communities have begun construction on the first home in Sanctuary Village, a Traditional Neighborhood Development (TND) located in the western mountains of North Carolina ...

Sanctuary Village will be a walkable, mixed-use village that will encompass 24 acres of multi-generational living with mansion flats, village houses, tree houses, mountain cottages and a civic/commercial component that will include shops, cafes, book stores, cultural events and community gathering spots a short stroll from homes.

We found this explanation of a Traditional Neighborhood Development:

a comprehensive planning system that includes a variety of housing types and land uses in a defined area. The variety of uses permits educational facilities, civic buildings and commercial establishments to be located within walking distance of private homes...

Haven Custom Homes emphasizes the advantages of building "in an off-site, climate controlled environment where the materials used in your home are protected from the weather."

- Precision construction resulting in straight walls, square corners, fitted windows and flat ceilings.

- Extra reinforcements in bearing walls.

- Move in 16-23 weeks after execution of a contract and your approval of final drawings and finish schedules.

Facts:

-

developers: Tim and Iva Ryan of

Sanctuary Communities

Sanctuary Communities

-

builder:

Haven Custom Homes

Haven Custom Homes

-

designer:

Allison Ramsey Architects (strategic partner)

Allison Ramsey Architects (strategic partner)

- location: "five blocks from Franklin's historic Main Street"

Links:

(Hat tip: Building Systems on October 29, 2008)

From the husband and wife team at  Taalman Koch Architecture comes news of a small development of 3 iT houses: Three Junipers.

Taalman Koch Architecture comes news of a small development of 3 iT houses: Three Junipers.

Situated on 5 acres of pristine high desert landscape, each house offers an uninterrupted view of Pipes Canyon and the Pioneertown sawtooth peaks...

The iT house utilizes a "light touch" installation approach, minimizing the construction footprint through use of smaller scale, modular elements and minimal packaging material.

In tandem with that announcement, a new itHouse website has been launched with:

- iT house configuration options

- details on the framing system

- explanation of the on-site assembly

Also worth a look: an informative blog following the construction of the first iT house.

(Hat tip: Jetson Green)

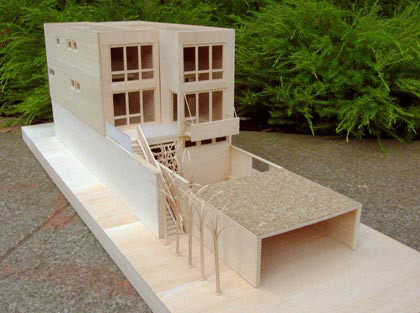

The Seattle Times reported a few weeks back on an attempt by Unico Properties to bring affordable housing to Seattle:

Several years ago, Unico lost some good downtown office tenants to outlying locations. Sperling says that when he asked the companies why they were moving, they told him most of their employees spent too much time commuting and couldn't afford to live in Seattle.

So, Unico turned to modular construction:

The company retained architectural firms Mithun and HyBrid to explore whether units could be built economically that might appeal to the design, environmental and technological tastes of young urbanites.

The result: the two Inhabit prototypes. The wood-frame units were built in a factory in Burlington, Skagit County, trucked to Seattle, and lifted by crane onto the plaza at the base of Unico's Rainier Tower.

For reference: Mithun, HyBrid Architecture.

The savings?

[The Inhabit units cost] 15 percent less than a conventional project.... [and] the prototypes were built in just three weeks. Units could be put together while other work is going on at the site, and neighbors wouldn't experience as much disruption.

Features of the units include:

- 480 - 675 sf

- studio - 1 bedroom

- 62 units total

- floor-to-ceiling windows, a "green" roof to reduce stormwater runoff

Our previous coverage of prefabs being used for similar high-density developments:

-

the KT2 from the new partnership between

KieranTimberlake and

KieranTimberlake and  LivingHomes

LivingHomes

- an mkLoft development in Denver

- a prefab hotel in London

(Hattip: Jetson Green)

We reported last year on retailer IKEA's prefab homes. More from The Guardian:

Britain's first "Ikealand" opened its metal-panelled pine doors yesterday in an experiment designed to spread the company's off-the-shelf principle from wardrobes and sofas to entire houses.The first of 93 flatpack homes designed and equipped by the household goods store went on show in Gateshead on Tyneside, where scores of would-be buyers are being vetted to ensure that their savings and income are modest enough to qualify....

Prices on the cul-de-sac off Marigold Avenue, where each unit comes with 22 Skimmia shrubs and an apple tree in the garden, range from £99,500 [$198,000] for a one-bedroom flat to £149,000 [$295,000] for a three-bedroom house...

Treehugger adds:

Seen as a way for them to get onto the property ladder, these houses will sell for $260,000 for a two bedroom townhouse. Assembled in a factory nearby, they get to the site ready to be bolted together and take about 16 weeks from start to completion.The system is called BoKlok (Ikea speak for smart living) and was developed in conjunction with Ikea.

I did a little research on prices in the area; these look competitive.

G Living commented on the TrailerWrap project:

While the low cost motive behind the introduction of mobile homes in the mid-1900s was a good one, the execution was often aesthetically reprehensible, shoddily constructed and inefficient energy-wise. TrailerWrap set out to take these small, dilapidated (often abandoned) structures and re-fashion them into something exciting and remarkable, yet sustainable and affordable.

Freshome covered the  Perrinepod:

Perrinepod:

a cute prefab home that can be built in just 3 days and withstand everything from earthquakes to cyclones.

The Good Human's Prefab Wednesday showed a prefab development in London that was covered last year on some of the other blogs.

Inhabitat's Prefab Friday featured the Single Hauz, a sort of house-meets-billboard:

...the idea takes shape in such a stylish little form that we can’t help ponder the challenge posed: how much space do you really need and where do you want it?

TreeHugger posted a video of  Adam Kalkin speaking about containers, and looked back at their enthusiasm of three years ago.

Adam Kalkin speaking about containers, and looked back at their enthusiasm of three years ago.

Michelle Kaufmann's  mkLoft will be used in a new development in Denver. From the Rocky Mountain News:

mkLoft will be used in a new development in Denver. From the Rocky Mountain News:

Denver developers Susan Powers and Chuck Perry are teaming with Kaufmann to put 40 factory-built town houses on 21 acres near Regis University at West 52nd Avenue and Federal Boulevard. The 1,100- to 1,500-square-foot town houses will be built at the All American Homes factory in Milliken, in Weld County, and trucked 60 miles, in sections, to the Denver site for assembly.That they're modular won't be apparent, as factory-built houses don't necessarily have the mass- produced, cookie-cutter look they did 30 years ago.

Read more about the plans in the full article.

Michelle Kaufmann Designs is one of the hottest companies in the modernist prefab world today. Right on the heels of the

Michelle Kaufmann Designs is one of the hottest companies in the modernist prefab world today. Right on the heels of the  mkLotus comes the announcement of the

mkLotus comes the announcement of the  mkLoft:

mkLoft:

This spacious 2-story, 2-bedroom + loft features a double-high ceiling in the living room, creating an open, harmonious environment for reflection and creativity.mkLoft™ is the perfect design for urban dwelling, whether you are looking to build your primary residence or live/work solution, a duplex, or a healthy community, this home can be designed in 2- or 3-story configurations to suit your needs....

mkLoft™ is also ideal in a multifamily development layout.

The Good Human was impressed:

She has done it again - come out with another stunning example of what a modern prefab can be.

Inhabitat noted the low price of the homes:

Depending on volume and finishes, the typical mkLoft ranges from $130 to $140/sf. This does not include the cost of land nor the permit approval process.

Developers are building a smaller development of three homes in Detroit:

The Hines family will be able to move into their new home within 30 to 45 days, once additions such as the front porch and garage are built. The Delmar Street homes are manufactured by Auburn Hills-based Champion Enterprises and cost from $170,000 to $210,000. They are between 1,700 square feet and 2,000 square feet.

The two homes assembled Thursday, and a third to be built later, are sold and include a full basement, two-car attached garages, three to four bedrooms, multiple baths and kitchen appliances."

A 23-unit modular development is rising in Grand Haven Township, Michigan:

The 11 duplex-style condo buildings will include composite fieldstone on the building's exterior....

They will be assembled on the site, along with garages and sunrooms. Each condo will have an inspection sheet when they're built in Indiana that will be completed by Michigan inspectors."