Here's an unexpected use of prefab. The folks at  kitHAUS have completed a display pavilion at the Westfield UTC Mall in San Diego. Tom Sandonato, of kitHAUS, gave us the details:

kitHAUS have completed a display pavilion at the Westfield UTC Mall in San Diego. Tom Sandonato, of kitHAUS, gave us the details:

We modified two K2 modules: one of the K2's as an open gazebo, the second as an all glass Gallery space.

Total time to install was two weeks with four weeks worth of design and shop fabrication...

In terms of promoting kitHAUS, we have a product display on site there inside the Gallery module, as well as vinyl art stating 'modules constructed by KitHAUS'."

These are the very same components we use to create the K3 units that are available for residential accessory structures. The K3 is large enough to be used as an outdoor studio, an office, a kids play room, etc — its uses are limitless, and with its size, it fits below the permitting requirements of most municipalities.

The kitHAUS K3 unit will be on display at the upcoming Dwell on Design show in San Francisco September 14-16."

A while back, I wrote about the models from  kitHAUS. The product features an aluminum framing system called

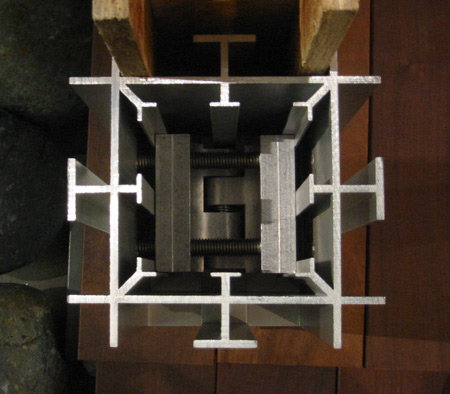

kitHAUS. The product features an aluminum framing system called  MHS (Modular Housing System) developed by US Systems LLC:

MHS (Modular Housing System) developed by US Systems LLC:

"Our modules are constructed on site in a matter of days, not months, and because of [the framing system's] lightweight properties can get into the hardest [to] reach places, without heavy equipment."

I had the chance to see the system for myself at the CA Boom show, and thought it was quite impressive. Clamps are used to hold the structural members together; bolts are only used to tighten the clamps. The kitHAUS reps did inform me that power tools are necessary to tighten the bolts, as hand tools wouldn't achieve the proper torque.

The system manufacturer's website has images, and even a cool video (MHS.WMV at the bottom of the main page) to show how the system comes together. For those interested, there are detailed reports on the structural testing of the system.